When cutting steel, carbide end mills for steel are very strong and heat-resistant. Special coatings like AlTiN can handle heat up to 1,400 °F. AlTiN Nano coatings can even handle heat up to 2,100 °F. These features make carbide tools great for fast cutting. They give smoother finishes and save time on extra polishing. HSS end mills for steel, however, wear out quicker and need sharpening often. But they are tough and cost less, so they work well for certain jobs. Choosing between these tools depends on your speed, budget, and material needs.

Key Takeaways

Carbide end mills cut hard metals like steel quickly and accurately. They handle heat well and don’t wear out easily, making them great for tough jobs.

HSS end mills cost less and work better on softer metals or slower tasks. They are strong and easy to sharpen, so they’re good for small projects.

Think about how hard the material is and how fast you need to work when picking carbide or HSS. Carbide is best for hard materials, while HSS works better for soft ones.

Carbide tools last longer and need less care, but they cost more at first. HSS tools are cheaper to buy but wear out faster and need replacing more often.

Using the right cutting fluids helps both carbide and HSS tools work better. It also makes them last longer and improves cutting results.

Overview of End Mills for Steel

What Are Carbide End Mills?

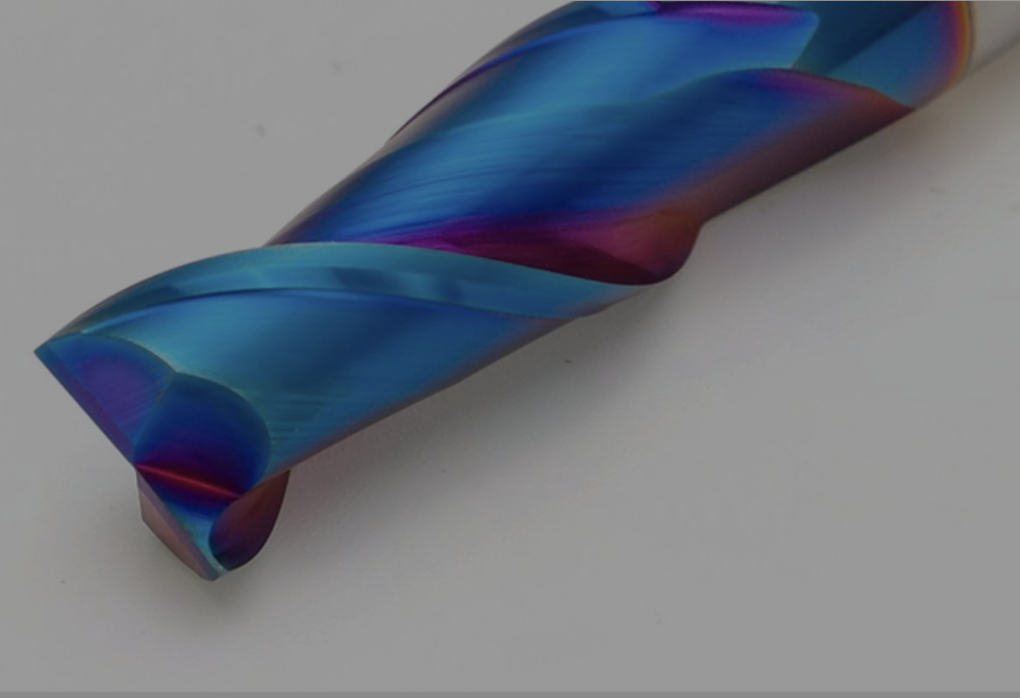

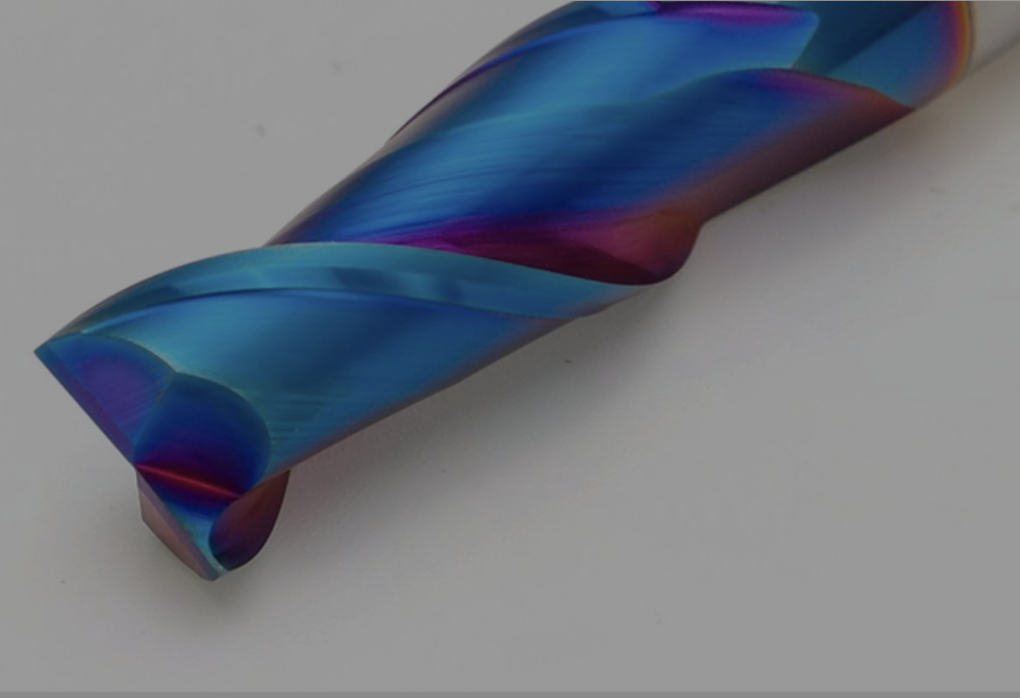

Carbide end mills are tools made from tungsten carbide and cobalt. They are very hard and resist wearing out, making them great for cutting steel. These tools can work fast and stay sharp even when hot. This makes them perfect for jobs needing accuracy and speed. Many carbide tools have special coatings like (Al,Cr,Si)N. These coatings help them handle heat and cut better.

Carbide end mills are best for fast cutting jobs. They are used for removing material, shaping, and making designs. They work well with tough metals like carbon steel and stainless steel. That’s why they are often used in factories.

What Are HSS End Mills?

HSS (High-Speed Steel) end mills are made from steel mixed with tungsten, molybdenum, and chromium. These tools are strong and can handle impacts, so they are good for stop-and-go cutting. HSS tools are not as hard as carbide ones but are less likely to chip or break.

HSS end mills are used for finishing and cleaning up edges. They are good for jobs where speed is not important but accuracy is. They also cost less, so they are a good choice for small projects or softer metals.

Key Differences in Composition and Properties

Carbide and HSS end mills are different in how they are made and how they work. Carbide tools are harder, so they stay sharp longer and work faster. HSS tools are tougher, so they can take hits without breaking.

Property | Carbide | HSS |

Hardness | Very high | High |

Toughness | Lower | Higher |

Edge Retention | Excellent | Good |

Heat Resistance | Superior | Moderate |

Cost | Higher initial investment | Lower initial cost |

Carbide end mills are best for fast, precise cutting. HSS tools are better for strong, low-cost jobs.

Performance Factors of Carbide vs. HSS

Cutting Speed and Efficiency

Carbide tools cut faster than HSS tools. They stay sharp at high speeds. This makes them great for quick machining jobs. Carbide tools remove material faster and save time. Industries use carbide end mills for steel when speed and accuracy matter.

HSS tools work slower but are good for detailed jobs. They are better for softer metals or precise designs. HSS tools are not ideal for big or fast projects.

Durability and Wear Resistance

Carbide tools last longer and resist wear. They stay sharp even under tough conditions. This makes them great for cutting hard materials like steel. HSS tools wear out faster, especially on hard metals or at high speeds.

HSS-Co tools depend on speed, feed rate, and cooling. HSS tools are less durable but tougher. They handle impacts and interruptions without breaking easily.

Heat Resistance and Thermal Stability

Carbide tools handle heat very well. They stay hard and sharp even when hot. You can use them for long periods without cooling often. Coatings like AlTiN improve carbide tools' heat resistance.

HSS tools have lower heat resistance. They work fine at slow speeds but struggle with heat during long use. For continuous cutting, carbide tools are better. For short or slow jobs, HSS tools work well.

Machining Quality and Surface Finish

When cutting steel, the cut quality and surface smoothness are important. Choosing between carbide and HSS end mills affects these results. Carbide end mills usually give better outcomes, especially for tough jobs.

Why Carbide End Mills Are Better

Carbide end mills stay sharp longer. This helps them cut smoothly and evenly. They work at high speeds, which reduces vibrations. Less vibration means fewer flaws on the surface. Carbide tools also cut hard materials well, making them great for steel.

Main benefits of carbide end mills:

Last longer and resist wear better.

Cut faster for quicker work.

Smoother finishes due to more cutting edges.

HSS End Mills and Their Uses

HSS end mills are good for certain tasks. They are tougher than carbide tools, so they don’t chip easily during rough cuts. But they are softer, so they don’t make fine finishes on hard metals like steel. HSS tools are best for softer metals or slow cutting.

Main benefits of HSS end mills:

Tougher for handling rough impacts.

Cheaper for smaller jobs.

Decent finish for simple tasks.

Comparing Surface Finish Features

The table below shows how carbide and HSS end mills differ in cutting quality and surface finish:

Feature | Carbide End Mills | HSS End Mills |

Durability and Wear | Lasts longer, resists wear better | Wears out faster, needs replacing more often |

Cutting Speed | Works well at high speeds | Best for slower speeds |

Material Hardness | Cuts hard metals easily | Best for softer metals |

Flute Count Effect | More flutes give smoother cuts and stability | Fewer flutes may lower performance |

Carbide end mills are best for precise cuts and smooth finishes. HSS tools are good for easier and less detailed jobs.

Cost-Effectiveness of Carbide and HSS End Mills

Initial Investment and Tooling Costs

The price of carbide and HSS end mills is important. Carbide end mills cost more at first. They are made with advanced materials and coatings, which makes them pricier. But they are worth it for fast and precise cutting.

HSS end mills are cheaper to buy. They are good for smaller budgets or jobs that don’t need high speed. If you work with softer metals or short projects, HSS tools save money while still working well.

Maintenance and Resharpening

Carbide end mills need less maintenance. They are very hard and resist wearing out, so they stay sharp longer. This means you don’t have to sharpen them often, saving time. But when they do need sharpening, it costs more and takes more effort.

HSS end mills are easier and cheaper to sharpen. You can sharpen them many times, which makes them last longer. However, they wear out faster, especially on hard metals like steel. This means you’ll need to sharpen them more often, which can increase costs.

Tool Lifespan and Long-Term Value

How long a tool lasts affects its value. Carbide end mills last much longer than HSS tools. They are tough and resist wear, making them great for long-term use in tough jobs.

HSS end mills don’t last as long. They are better for occasional use or less demanding projects. Even though they cost less upfront, replacing them often can make them more expensive over time.

Feature | Carbide End Mills | High-Speed Steel (HSS) Tools |

Speed | Works faster | Slower cutting |

Durability | Lasts longer | Wears out sooner |

Cost | Costs more upfront | Cheaper to buy |

Tool Life | Longer-lasting | Shorter lifespan |

Precision | Very accurate | Less precise |

CAM Compatibility | Works great | Limited use |

Carbide end mills are better for long-term use because they last longer and work faster. HSS tools are good for short-term jobs or when you have a small budget. Pick the right tool based on your needs and money.

When to Use Carbide End Mills

Carbide end mills are great for fast and precise cutting. Use them for hard metals like carbon steel or stainless steel. They are very strong and resist heat, making them perfect for tough jobs. For big projects or detailed designs, carbide tools last longer and work better.

These tools work well with special cutting fluids. Fluids like vegetable oil-based lubricants help reduce heat and friction. They also make the tools last longer and improve cutting results. Using these fluids makes carbide tools even more effective.

Carbide tools are best for smooth finishes. They stay sharp at high speeds, reducing vibrations. This helps create flawless surfaces. Industries like aerospace and car manufacturing often use carbide tools for steel machining.

When to Use HSS End Mills

HSS end mills are good for jobs needing toughness and lower costs. Use them for small projects or softer metals. They handle impacts well, making them great for stop-and-go cutting.

HSS tools are better for slower jobs. They are good for cleaning edges or detailed finishing. These tools are easy to sharpen, which saves money over time.

HSS tools work with eco-friendly cutting fluids like rubber seed oil. These fluids improve cutting and are better for the environment. If your budget is small or you need frequent tool changes, HSS tools are a smart choice.

Factors to Consider: Material Hardness, Speed, and Budget

Picking the right tool depends on several things. Hard metals need carbide tools, while softer metals work better with HSS tools. For tough alloys like die steel D2, carbide tools are more durable and precise.

Speed matters too. Carbide tools cut faster, making them great for big jobs. HSS tools work slower but are better for detailed tasks.

Budget is also important. Carbide tools cost more upfront but last longer and need less maintenance. HSS tools are cheaper to buy but wear out faster, making them better for short-term projects.

To choose wisely, test tools on real materials or ask experts for advice. Trying new technologies can improve cutting and save money. Regular updates to your tools also help meet sustainability goals.

Picking the right end mill depends on your project needs. Carbide end mills are great for fast, accurate cutting. They work best with hard steels or big jobs. Their hardness and heat resistance make them perfect for tough tasks.

HSS end mills are strong and cheaper. They are better for slower work or softer metals. These tools are good for testing designs or saving money.

Tool Type | Advantages | Disadvantages |

Uncoated HSS End Mills | Cheaper, good for soft metals or test projects | Wears out faster on hard metals |

Carbide End Mills | Harder, handles heat, great for tough metals | Costs more at first |

In the end, pick based on cost, performance, and job needs.

FAQ

What is the main advantage of carbide end mills over HSS?

Carbide end mills are harder and resist heat better. They cut faster and last longer. This makes them great for tough jobs and hard metals like steel.

Tip: Pick carbide tools for accurate and quick work on big tasks.

Are HSS end mills suitable for cutting steel?

Yes, HSS end mills can cut steel but work slower. They cost less and are tougher, making them good for small jobs or softer metals.

How do coatings improve end mill performance?

Coatings like AlTiN or TiCN lower heat and friction. They make tools stronger and cut better, especially carbide ones. Coated tools last longer and give smoother results.

Which end mill is better for beginners?

HSS end mills are better for beginners. They cost less, are easy to sharpen, and handle mistakes well. For learning or testing, HSS tools are a smart pick.

How do I choose the right end mill for my project?

Think about material hardness, speed, and cost. Use carbide for hard metals and fast jobs. Pick HSS for softer materials or if saving money matters.

Note: Try tools on your material to find the best option.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg