Which square end mill works best for your metal jobs

Image Source: pexels

Choosing the right square end mill is essential for quality metalworking. For aluminum applications, the Hiboo Tools Carbide Square End Mill stands out as the top choice in 2025, offering excellent chip removal and a smooth surface finish. When working with steel, the Hiboo Tools High-Performance Square End Mill delivers outstanding results. Leading brands such as Niagara Cutter and SPEED TIGER also provide square end mill options known for their strength and precision. Selecting the appropriate square end mill not only speeds up your workflow but also extends tool life and enhances the appearance of your finished parts. Factors like tool coatings, flute count, and geometry play a crucial role in performance. Relying on high-quality square end mills ensures you complete projects efficiently and consistently meet strict industry standards.

Key Takeaways

Pick square end mills based on the metal you cut. Aluminum and steel need different tools for good results.

Use carbide end mills with 2 or 3 flutes for aluminum. High helix angles help clear chips fast. This gives smooth finishes.

For steel, use carbide end mills with 4 flutes. TiAlN coatings help resist heat and wear. This makes strong, smooth cuts.

Match your end mill’s flute count, coating, and shape to your machine’s power. Think about what the job needs for faster, cleaner work.

Set the right speeds and feeds for your metal and tool. This helps avoid tool damage and gives better surface quality.

Keep your end mills sharp and clean. Store them the right way to make them last longer and cut better.

Do not use dull tools, wrong feeds, or deep cuts. These mistakes can break tools and give bad finishes.

Hiboo Tools sells high-quality carbide square end mills. They have advanced coatings and are made very carefully for good metalworking.

Best Square End Mill Comparison

Image Source: unsplash

Aluminum vs. Steel: Key Differences

When you pick a square end mill, think about the metal you will cut. Aluminum and steel need different tools because they are not the same. Aluminum is softer and can stick to the tool. Steel is harder and makes more heat when you cut it. These things change which end mill works best.

Aspect | Aluminum Machining Requirements | Steel Machining Requirements |

Material Properties | Softer, more pliable, prone to chip welding and clogging | Harder, more abrasive, higher cutting forces and heat |

Tool Material | Solid carbide preferred for rigidity and high-speed cutting | Tools designed for toughness and wear resistance |

Flute Count | 1 or 2 flutes for better chip evacuation | More flutes to handle harder material and reduce tool load |

Flute Design | Larger flutes, sharper edges, high helix angles | Geometry optimized for strength and heat dissipation |

Coating | Often uncoated or special coatings to reduce heat and wear | Wear-resistant coatings to withstand abrasion and heat |

Cutting Speed & Feed | Higher speeds and feeds for better finish and chip removal | Lower speeds, feeds adjusted for tool life and finish |

Chip Evacuation | Critical; large flute volume and single/two-flute designs help | Less critical; chips are harder but less sticky |

Cooling | Coolant or air blast recommended | Coolant used to manage heat and tool wear |

Tool Rigidity | Solid carbide to minimize deflection at high speeds | Tools designed for toughness under heavy loads |

End Mill Geometry | Square end mills with sharp corners for slotting and contouring | Geometry optimized for durability and surface finish |

The way each metal acts changes how your end mill should look. Aluminum needs fewer flutes and bigger spacesbetween them. This helps chips get out fast and lets you cut deeper. Steel needs more flutes for extra strength and to last longer. Square end mills with sharp corners must be strong and work well for both metals.

Top Models and Specs

There are many square end mills for aluminum and steel. Top brands make special models for different jobs. The table below shows some of the best models for 2025. It lists the most important features for people who use these tools at work.

Brand/Model | Material | Coating | Flute Count | Geometry/Helix Angle | Ideal Applications |

Hiboo Tools Carbide Square End Mill (Aluminum) | Carbide | ZrN | 2/3 | High helix (42°) | Aluminum slotting, contouring |

Hiboo Tools High-Performance Square End Mill (Steel) | Carbide | TiAlN | 4 | Variable helix | Steel slotting, finishing |

Niagara Cutter N560 (Aluminum) | Carbide | Uncoated/ZrN | 3 | High helix | High-speed aluminum cutting |

SPEED TIGER IAUE (Steel) | Carbide | TiAlN | 4 | Standard helix | Steel, alloy, general machining |

SwiftCarb AF5 Series (Aluminum) | Carbide | Uncoated | 2 | High helix | Aluminum, non-ferrous metals |

Kennametal HARVI I TE (Steel) | Carbide | TiAlN | 4 | Variable helix | Steel, stainless, titanium |

OSG AE-VMS (Steel) | Carbide | TiAlN | 4 | Variable helix | Steel, mold, die |

CGS Tool S-Carb (Aluminum) | Carbide | ZrN | 3 | High helix | Aluminum, aerospace |

SAMHO Solid End Mill (Steel) | Carbide | TiAlN | 4 | Standard helix | Steel, tool steel |

6G Tools ZrN Coated (Aluminum) | Carbide | ZrN | 2 | High helix | Aluminum, copper |

Harvey Tool 2-Flute (Aluminum) | Carbide | Uncoated | 2 | High helix | Aluminum, plastics |

Seco Jabro (Steel) | Carbide | TiAlN | 4 | Variable helix | Steel, high-temp alloys |

SHARPRO 4-Flute (Steel) | Carbide | TiAlN | 4 | Standard helix | Steel, cast iron |

You should look for the right mix of material, coating, flute count, and shape for your job. Carbide end mills are popular because they are hard and can take heat. For aluminum, pick 2 or 3 flutes and a high helix angle. This helps chips move out and gives a smooth finish. For steel, use 4 flutes and a strong coating like TiAlN. This makes the tool last longer and work better on tough jobs.

If you cut soft metals, hss end mills can save money for slow or easy cuts. But carbide end mills work better and last longer in most shops.

Tip: Always match your end mill’s flute count and coating to your metal and cutting speed. This helps your tool last longer and gives you better results every time.

How to Choose the Right End Mill

Image Source: pexels

Picking the right end mill helps you get good results. You want your work to look nice and finish fast. Think about what metal you are cutting. Also, think about the kind of cut and what your machine can do. Let’s look at what matters for aluminum and steel. Then, see how your job and machine affect your choice.

For Aluminum: Selection Tips

Material and Coating

Aluminum can stick to tools and wear them out. Solid carbide end mills work best because they stay sharp. They also handle high speeds well. Coatings like Zirconium Nitride or Titanium Diboride help stop sticking. These coatings also make the tool last longer. You can cut faster with these coatings.

Pick carbide for strong and heat-resistant tools.

Use ZrN or TiB2 coatings to stop wear and sticking.

HSS end mills are okay for slow or easy jobs, but carbide is better for most work.

Flute Count and Geometry

Aluminum needs chips to leave the cut fast. Use end mills with 2 or 3 flutes. Fewer flutes mean bigger spaces for chips to get out. This keeps the cut smooth and stops clogging. A high helix angle helps chips move out and gives a nice finish.

Tip: Sharp, polished flutes and a small corner radius work best for aluminum.

2 or 3 flutes help clear chips well.

High helix angle makes cutting smooth and fast.

Variable pitch and polished flutes lower vibration and built-up edge.

For Steel: Selection Tips

Material and Coating

Steel is much harder than aluminum. You need a tough end mill for steel. Carbide end mills are best because they do not wear out fast. Look for coatings like Titanium Aluminum Nitride. This coating protects the tool from heat and rubbing.

Use carbide for hard and long-lasting tools.

Pick TiAlN coating for heat protection and smooth cuts.

Do not use uncoated tools for steel because they wear out fast.

Hardness and Geometry

Steel needs more flutes, usually 4 or 5. More flutes spread out the cutting force and give a better finish. The right shape, like a chip breaker flute and a small edge radius, helps balance force and tool life. Shorter end mills are stiffer and help you cut with more accuracy.

4 or 5 flutes give strength and a nice finish.

Chip breaker flute design helps chips leave the cut.

Shorter tools are stiffer; use longer ones only for deep cuts.

Application and Machine Fit

Your job and machine matter when picking an end mill. Match the end mill’s shape, size, and shank to your job. Square end mills work well for slotting, side milling, and finishing. Always check your machine’s spindle power, torque, and tool holding before picking a size.

Factor | Influence on End Mill Selection |

Job Type | Decides end mill shape and size; square end mills are good for slotting, side milling, and finishing. |

Machine Compatibility | Changes shank type, tool size, and material; machines have limits for spindle power and torque. |

End Mill Diameter | Bigger diameters cut faster but need more power; smaller ones are good for detail work. |

Tool Length/Flutes | Shorter tools are stiffer; flute count changes chip removal and finish. |

Note: Always use the shortest tool that can reach your cut. This makes your tool more accurate and stiff.

If you focus on these things, your end mill will fit your metal, job, and machine. This means you work faster, your tools last longer, and your parts look better.

Square End Mill Reviews 2025

Aluminum: Top Picks

Hiboo Tools Carbide Square End Mill

The Hiboo Tools Carbide Square End Mill is great for aluminum. It gives you both speed and accuracy. This tool uses strong carbide, so it stays hard and lasts longer. The ZrN coating helps stop aluminum from sticking. It also lowers friction and keeps the tool cool. The high helix angle lets chips move away fast. This keeps your work area clean. The sharp corners help you make flat cuts and slots.

Pros:

Chips move out fast for smooth, quick cutting

ZrN coating helps the tool last longer and stops buildup

Strong carbide makes the tool tough and reliable

Sharp shape gives you neat, square cuts

Cons:

Best Use Cases:

Making slots and shapes in aluminum parts

Fast finishing for car and airplane parts

Jobs where a nice surface is important

SwiftCarb AF5 Series

The SwiftCarb AF5 Series is known for its high helix shape and micro-grain carbide. It removes material quickly and leaves a shiny finish. The uncoated type is good for soft aluminum. The ZrN-coated type works better for harder jobs. Many people like this end mill because it is fast and gives a smooth surface.

Pros:

High helix shape helps chips leave and lowers shaking

Micro-grain carbide makes it strong and less likely to bend

You can pick coated or uncoated types

Cons:

Best Use Cases:

Fast roughing and finishing in aluminum

Cutting thin or delicate parts

Jobs that need a shiny, smooth finish

6G Tools ZrN Coated Square End Mill

The 6G Tools ZrN Coated Square End Mill is a good choice for aluminum. The ZrN coating stops sticking and helps the tool last longer. It has two flutes, so chips clear out easily. This is important for deep cuts and fast work.

Pros:

ZrN coating stops wear and buildup

Two flutes help chips get out fast

Good quality and value for making many parts

Cons:

Best Use Cases:

Deep slots and pockets in aluminum

Making lots of parts where tool life matters

General cutting of copper and brass

Carbide square end mills work better than HSS tools for aluminum. They cut faster and last up to five times longer. Coatings like ZrN and TiB2 make them even better and help them wear less.

Steel: Top Picks

Hiboo Tools High-Performance Square End Mill

The Hiboo Tools High-Performance Square End Mill is tough enough for steel. It is made of carbide and has a TiAlN coating. This coating protects the tool from heat and rubbing. The four flutes spread out the cutting force and make the finish smoother. You can use it for many steel jobs like slotting and finishing.

Pros:

TiAlN coating helps with heat and makes the tool last

Four flutes give strength and a smooth finish

Strong carbide is good for hard jobs

Cons:

Best Use Cases:

Slotting and finishing in carbon and alloy steels

Cutting tool steels and stainless steels

Jobs where you need a nice finish and strong tool

SAMHO Solid End Mill

The SAMHO Solid End Mill is a trusted tool for steel. It has a strong carbide body and a TiAlN coating. This helps it last longer in tough jobs. The standard helix and four flutes make it good for many steel tasks.

Pros:

Strong carbide and tough coating

Handles heavy cuts and fast feeds

Works well for roughing and finishing

Cons:

Best Use Cases:

SPEED TIGER 4 Flute Square End Mill

The SPEED TIGER 4 Flute Square End Mill is made for steel. The TiAlN coating keeps it cool and helps it last. Four flutes let chips move out and make the finish smooth. You can use this tool for roughing and finishing.

Pros:

Great heat resistance for fast cutting

Four flutes balance strength and chip flow

Always gives good results

Cons:

Best Use Cases:

Finishing and side milling in steel and alloys

Fast cutting of hard steels

Jobs that need tight sizes and smooth finishes

Carbide square end mills with TiAlN coating are best for steel. They last long, resist heat, and can run fast. Brands like Cleveland and Kyocera are also good for steel jobs.

Pros, Cons, and Use Cases

Model/Brand | Pros | Cons | Best Use Cases |

Hiboo Tools Carbide Square End Mill | Chips clear fast, ZrN coating, strong carbide | Not for steel or hard alloys | Aluminum slotting, shaping, finishing |

SwiftCarb AF5 Series | High helix, micro-grain carbide, smooth finish | Wears faster in rough aluminum | Fast aluminum cutting, thin parts |

6G Tools ZrN Coated Square End Mill | ZrN coating, two flutes, good value | Only for non-ferrous metals | Deep slots in aluminum, copper, brass |

Hiboo Tools High-Performance Square End Mill | TiAlN coating, four flutes, tough carbide | Not for non-ferrous metals | Steel slotting, finishing, tool steels |

SAMHO Solid End Mill | Strong carbide, TiAlN coating, flexible use | Not best for soft metals | General steel cutting, heavy slotting |

SPEED TIGER 4 Flute Square End Mill | Heat resistance, four flutes, always good quality | Not for deep slots in soft materials | Steel finishing, fast cutting |

Square end mills are best for flat cuts and sharp corners. Use high helix or variable helix for aluminum to cut faster and lower shaking. For steel, TiAlN-coated carbide end mills last longest and give the best finish.

Pick a square end mill for general cutting, slotting, and finishing in aluminum and steel.

Use single or two-flute carbide end mills for aluminum to help chips move out.

Choose four-flute carbide end mills with TiAlN coating for steel to make the tool last and get a smooth finish.

Do not use aluminum-based coatings on aluminum because it can hurt the tool.

For tough steel jobs, brands like Kennametal and Sandvik are good choices.

You get the best results when you match the end mill’s shape, coating, and flute count to your metal and job. This way, you get high quality, longer tool life, and fast cutting in your projects.

Expert Tips for End Mill Performance

Speeds and Feeds

You get the best results when you set speeds and feeds right. Speed means how fast the tool spins. Feed rate is how quickly the tool moves through metal. If you go too fast or too slow, you can hurt the tool or get a rough finish. For aluminum, use faster speeds and medium feeds. For steel, go slower and feed carefully.

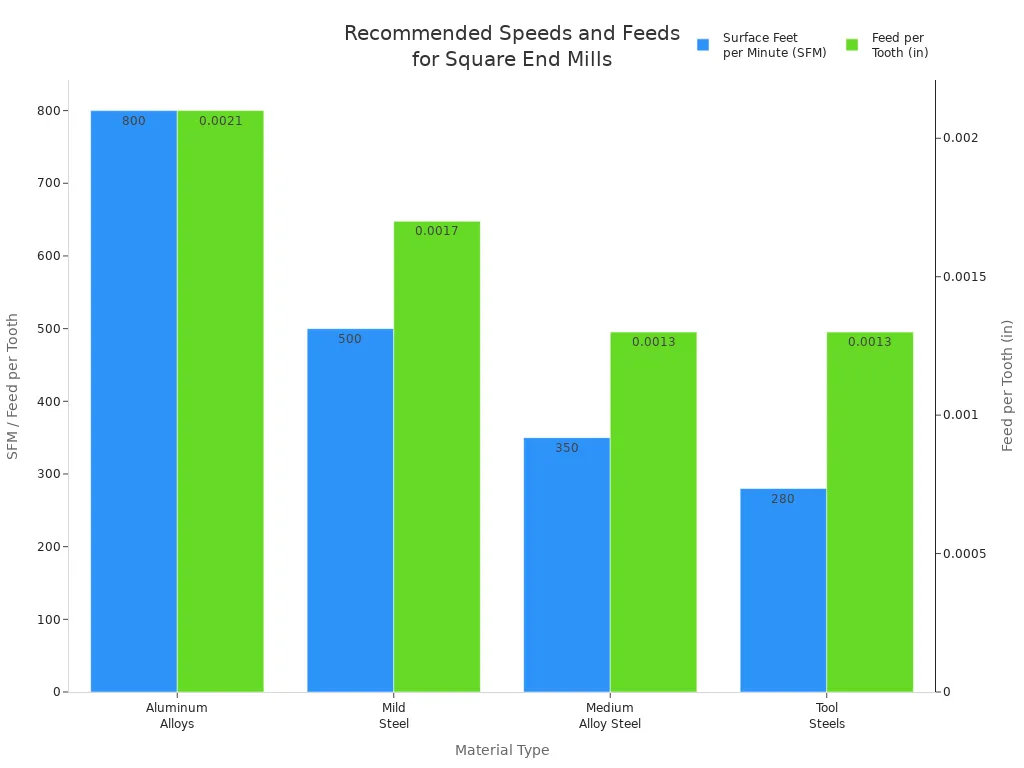

Here is a table to help you pick speeds and feeds for square end mills:

Material Type | Example Material | Surface Feet per Minute (SFM) | Feed per Tooth (inches/tooth) for 1/4" (6mm) Diameter |

Aluminum Alloys | (General) | 600-1000 | 0.0017" to 0.0025" |

Mild Steel | 1018 | 500 | 0.0017" |

Medium Alloy Steel | 4140 | 350 | 0.0013" |

Tool Steels | A2, D2, H13, P20 | 280 | 0.0013" |

Tip: Always look at the manufacturer's rules for your end mill. Change speeds and feeds for your metal and tool size. This keeps your tool working well and lasting longer.

When you use the right speeds and feeds, you control chips and heat. This stops the tool from breaking and keeps your finish smooth. You also make more parts with each tool, which saves money and time.

Maintenance and Longevity

You can make your end mill last longer with simple care. Good care gives you better results and means you do not need new tools as often.

Sharpen and recoat your end mill if it gets dull. This makes it cut well again and saves money.

Use coatings like TiAlN or ZrN to protect your tool from heat and wear.

Cut slower when working with hard or rough metals. This helps your tool last longer.

Use strong coolant to clear chips and keep the tool cool.

Store your tools in a dry, clean place. Handle them gently so they do not chip or break.

Note: Clean your end mill after every use. Check for damage before each job. This keeps your cuts good and your tools ready.

Mistakes to Avoid

You can stop problems by watching out for these mistakes with square end mills. Each mistake can make your tool wear out, break, or give a bad finish.

Common Mistake | Causes / Issues | How to Avoid / Fix |

End Mill Breakage | Too much feed, deep cuts, long tool, dull tool | Lower feed, cut less, hold tool deeper, use short tool, sharpen tool |

Unusual End Mill Wear | Too fast, hard metal, wrong angles, chips cut again | Slow down, use coatings, check angles, use more coolant |

Short Tool Life | Too much rubbing, hard metal, wrong angles | Sharpen tool, use coatings, fix angles |

End Mill Chipping | Heavy feed, tool not stiff enough | Lower feed, use short tool, hold tool deeper, climb milling |

Excess Chip Packing | Big cuts, not enough chip space, not enough coolant | Cut less, use fewer flutes, use more coolant |

Burrs | Dull tool, wrong feed or speed, wrong angle | Sharpen tool, fix feed and speed, set right angle |

Rough Surface Finish | Heavy feed, slow speed, worn tool, wrong angle | Fix feed and speed, change tool, check tool shape |

Remember: Careful setup and regular checks help you stop mistakes and keep your cuts looking great.

Hiboo Tools Brand Spotlight

About Hiboo Tools

You want a partner who knows cutting tools well. Hiboo Tools is in Changzhou, Jiangsu, China. They have been making square end mills for over 12 years. The company makes and sells carbide cutting tools for CNC machines. They can make up to 50,000 tools each month. They also keep more than 20,000 cutters ready in stock. This means Hiboo Tools can fill orders fast when you need them. Their products include square end mills with HRC58 hardness and TiSiN coatings. You can pick from many flute options. Hiboo Tools uses new technology and always has tools ready. This helps your factory keep working without delays.

Why Choose Hiboo Tools

You want tools that work the same every time. Hiboo Tools is special because they use advanced machines and check quality closely. They use CNC grinding machines, like ANCA and 5-axis models. Skilled workers run these machines. Every end mill is checked with Zoller measuring machines. This makes sure the size and material are right. Hiboo Tools can also make custom tools for your needs. They work with you to help your machining jobs go better. The company cares about the environment and makes tools in a clean way.

Aspect | Description |

Manufacturing Equipment | Uses CNC and 5-axis grinding machines for high precision |

Inspection Protocols | Checks tools for accuracy, strong materials, and good performance |

Skilled Operators | Trained workers make sure each tool is high quality |

Customized Solutions | Makes special end mills with your team’s help |

Sustainable Practices | Makes tools in ways that are good for the environment |

Quality Commitment | Checks quality at every step so tools last and work well |

When you pick Hiboo Tools, you get good quality, help from experts, and a worldwide supply that keeps your work moving.

Popular Square End Mills

You need end mills that can cut aluminum and steel well. Hiboo Tools sells top square end mills made from carbide and tungsten cobalt alloy. These tools have coatings like TiAlN and AlTiN. The coatings help the tools last longer and cut faster. You can choose how many flutes and what helix angle you want. Hiboo Tools also makes small tapered square end mills. These are great for side cuts, shaping, and angled slots. The tapered shape stops shaking and bending. This gives you better cuts and makes the tool last longer.

Small tapered square end mills for side cuts and shaping

Carbide tools are strong, fast, and give smooth finishes

Special coatings (TiAlN, AlTiN) protect from heat and wear

Good shapes for deep holes, 3D cuts, and moving chips out

You can pick flute design, taper angle, and coating you need

Every tool is checked to make sure it is high quality

You save money with tools that work well for big jobs in mold making, aerospace, and general machining. Hiboo Tools focuses on quality, trust, and expert help. This helps you get better results and stay ahead of others.

You want your metal work to turn out great. Hiboo Tools is a good choice for both aluminum and steel. Their tools last a long time and work well. When you pick a square end mill, think about what you need:

Hobbyists should have both two-flute and four-flute end mills. This gives you more ways to cut different metals.

Professionals get faster work and smoother parts with multi-flute carbide tools.

If you want to save money, buy a few strong carbide end mills instead of many cheap ones.

Always pick the right tool for your job and machine. Good tools and help from experts make your work more accurate and help you work without stopping.

FAQ

What is the main advantage of using a carbide square end mill for metalworking?

Carbide square end mills give you high hardness and wear resistance. You get longer tool life and better surface finishes. These tools work well at higher speeds, which helps you boost productivity in your shop.

How do you choose the right flute count for your application?

Use 2 or 3 flutes for aluminum to clear chips quickly. Choose 4 or more flutes for steel to increase strength and improve surface finish. Always match flute count to your material and cutting speed.

How often should you replace or resharpen your end mills?

Check your end mills after each job. Replace or resharpen them when you see dull edges, chipping, or poor surface finish. Regular inspection helps you avoid tool failure and keeps your production running smoothly.

Can you use the same end mill for both aluminum and steel?

You should not use the same end mill for both metals. Aluminum and steel need different coatings and geometries. Using the right tool for each metal gives you better results and longer tool life.

What coatings work best for square end mills in steel machining?

TiAlN and AlTiN coatings work best for steel. These coatings protect your tool from heat and wear. You get longer tool life and smoother finishes when you use coated end mills for steel.

How do you prevent chip buildup during high-speed machining?

Use end mills with polished flutes and high helix angles. Apply coolant or air blast to clear chips. Reduce feed rate if you see chip packing. Good chip control keeps your cuts clean and your tools safe.

What should you look for in a reliable end mill supplier?

Key Factor | Why It Matters |

Consistent Quality | Ensures predictable performance |

Fast Delivery | Reduces downtime in your operations |

Technical Support | Helps you solve machining challenges |

Custom Solutions | Meets your unique production needs |

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg