Corner rounding end mill solutions for perfect finishes

Image Source: pexels

Harvey Tool, Maritool, Niagara Cutter, Hiboo Tools, and Micro 100 are top brands for machinists seeking perfect finishes with their corner rounding end mill tools.

Every corner rounding end mill from these brands performs exceptionally well, delivers a great finish, and offers long-lasting durability.

Choosing the right corner rounding end mill significantly impacts the quality of your machining results. The table below illustrates how selecting the proper tools and adjusting cutting parameters affect surface finish smoothness:

Parameter | Impact on Surface Finish Quality |

Feed | 70.22% contribution (most important) |

Cutting Speed | 21.93% contribution |

Tool Coating | Multilayer coatings give finishes close to grinding |

Surface Roughness (Ra) | 0.566–0.994 μm reached with the best machining |

Machinists achieve smoother and more attractive results when they choose the best corner rounding end mill for each specific job.

Key Takeaways

Selection Criteria

Material and Coating

Machinists pick corner rounding end mills by looking at tool material and coating. Carbide tools last a long time and do not wear out fast. These are good for tough jobs. High-speed steel (HSS) costs less but wears out quicker. Cobalt tools are harder and handle heat better than HSS. Some coatings like titanium nitride (TiN), titanium carbonitride (TiCN), and aluminum titanium nitride (AlTiN) make tools harder. These coatings also help tools move smoother and cut faster. Diamond coatings are best for very hard or rough materials. Picking the right tool and coating helps tools last longer and makes the finished corners look better.

Tip: The right material and coating help stop chipping and tool wear. This gives smoother finishes and makes tools last longer.

Radius and Pilot Diameter

The corner radius and pilot diameter change how the edge looks. The corner radius sets how round the edge will be. The pilot diameter helps guide the tool along the workpiece. A bigger pilot diameter keeps the tool steady. A smaller pilot diameter lets you make more detailed edges. Sometimes machinists use a small radius tool or chamfer the material first. This helps the tool last longer and gives a smoother finish. The cutter diameter and tool radius also help spread out the load and clear chips. This is important for keeping the finish even. Picking the right pilot diameter and corner radius gives the best results for each job.

Flared vs. Unflared Corner Rounder

A flared corner rounder has a small flare, about 5 degrees, on the pilot and shoulder. This helps the corner blend smoothly into the workpiece. It also stops problems like steps or cuts that go too deep. Flared tools are easier to set up and often do not need extra finishing. But they do not make a full radius. An unflared corner rounder makes a full radius but needs careful setup. If not set up right, it can leave steps or ridges. Flared corner rounders save time and are easier to use. Unflared corner rounders are best when you need a full radius and can set up the tool very carefully.

Top Corner Rounding End Mills

Harvey Tool

Harvey Tool is well known for its corner rounding end mill solutions. The company uses solid carbide, so the tools last a long time and do not wear out fast. Each tool has a special flute shape with a positive rake. This shape helps make smooth finishes and removes chips easily. The 2° flare angle lets the tool make gentle edges on parts. Harvey Tool moves the radius center by 0.005 inches from the tool’s end. This helps machinists get very accurate results.

The AlTiN Nano coating makes the tool harder and helps it handle heat. This coating lets machinists use faster speeds without losing finish quality. The h6 shank tolerance means the tool fits tightly in holders for high-precision work. Harvey Tool makes its corner rounding end mill tools in the USA using advanced CNC grinding. The company also gives users helpful resources like speeds and feeds charts, CAM tool libraries, and simulation files.

Feature | Description |

Material | Solid carbide |

Flute Design | Helically ground, positive rake |

Flare Angle | 2° for smooth transitions |

Radius Center Offset | 0.005” from tool end |

Coating | AlTiN Nano for hardness and heat resistance |

Shank Tolerance | h6 for high precision |

Manufacturing | CNC ground in the USA |

Performance Optimization | Machining Advisor Pro, speeds & feeds charts, CAM libraries |

Pros:

Gives very accurate cuts and smooth finishes

Lasts a long time and resists wear

Offers lots of technical help for machinists

Cons:

Ideal Use Cases:

Note: Harvey Tool’s corner rounding end mill is a great pick for machinists who want the best finish and dependability.

Maritool

Maritool has many corner rounding end mill choices. The company uses high-quality carbide, so the tools last longer in tough jobs. Maritool makes sure its tools have sharp edges and tight tolerances. These features help machinists get the same good results every time and need less extra finishing.

Maritool’s corner rounding end mill tools come in flared and unflared types. The flared type helps blend the edge into the part, while the unflared type makes a full radius. Maritool tools usually cost less than some top brands, so they are a good deal for shops that want good tools without paying the most.

Pros:

Cons:

Ideal Use Cases:

Niagara Cutter

Niagara Cutter is known for making strong and high-performing corner rounding end mill tools. The company uses advanced carbide and offers different coatings like TiAlN and AlTiN. These coatings help the tools last longer and handle heat during hard jobs.

Niagara Cutter designs its tools to remove chips well and cut smoothly. Many tools have a helical flute shape, which helps clear chips and keep the finish clean. Niagara Cutter also makes special tools for undercutting and deburring.

Pros:

Cons:

Ideal Use Cases:

Hiboo Tools

Hiboo Tools is a good choice for shops that want affordable corner rounding end mill tools. The company uses both carbide and high-speed steel, so machinists can pick what fits their budget and needs. Hiboo Tools focuses on simple designs that work well for most jobs.

Hiboo Tools’ corner rounding end mill may not have as many special coatings or features as expensive brands. But these tools still work well for the price. Hiboo Tools is popular with shops that need to save money but still want a decent finish.

Pros:

Cons:

Ideal Use Cases:

Micro 100

Micro 100 makes high-precision cutting tools, including corner rounding end mill products. The company uses very fine carbide and advanced grinding. This gives the tools sharp edges and tight tolerances. Micro 100 has both flared and unflared types, so machinists can pick the right one for each job.

Micro 100’s corner rounding end mill tools often have a polished finish for better chip flow. The company also makes special tools for deburring and undercutting. Micro 100 tools cost more than basic brands, but they give great results in tough jobs.

Pros:

Very precise and sharp edges

Special designs for deburring and undercutting

Polished finish helps chips move away

Cons:

Ideal Use Cases:

Tip: Micro 100’s corner rounding end mill is a great choice for machinists who need tight tolerances and special options.

Corner Rounding End Mill Comparison

Key Specs Table

Machinists look at important details when picking a corner rounding end mill. The table below shows what makes each tool different. It lists things like shape, size, form, flute count, helix direction, material, and coatings. These details help people choose the best tool for their job.

Specification | Description & Differentiation |

Shape | Bull-nose end mills have both flat and rounded parts. They make smooth inside corners and help avoid rough spots. |

Size | Bigger tools take away more material but are not as detailed. Smaller tools give more detail but can break more easily. |

Form | Straight end mills cut straight walls. Tapered end mills are stronger for slanted walls but cannot cut straight walls. |

Flute Count | Fewer flutes move chips out better. More flutes make smoother finishes but do not clear chips as well. |

Helix Direction | Up-cut moves chips up for clean bottoms. Down-cut makes the top smooth. Compression does both at once. |

Material & Coatings | HSS costs less but gets dull faster. Carbide lasts longer. Coatings like TiAlN and AlTiN help tools last even longer. |

Note: Picking the right corner radius and pilot diameter helps machinists get smoother finishes and longer tool life.

Performance Overview

Top brands of corner rounding end mills work well for tool life, finish, and speed. Carbide tools with TiAlN or AlTiN coatings fight wear and heat. This lets machinists use faster speeds. A steady pilot diameter, like the 0.107-inch size in some Harvey Tool models, makes setup simple and accurate. The corner radius design spreads out stress and stops chipping. This gives smoother surfaces.

Machinists get the best results when they match the corner radius and cutter diameter to the job. Using the biggest pilot diameter possible makes the tool more stable. The tool radius and corner radii help the tool handle stress and clear chips. Shops that use sharp tools, balanced holders, and good cooling get better finishes. Checking and sharpening the tool often keeps it working well.

Feed rate and speed change with the material. For steel, feed rates are 0.04 to 0.12 mm per tooth. For aluminum, rates can go up to 0.40 mm per tooth.

Carbide tools with coatings last longer and run faster.

Rounded corners lower chatter and make the finish look better.

Tip: Always match the corner radius, pilot diameter, and cutter diameter to the material and job for the best results.

Choosing the Right Corner Rounding End Mill

Application Fit

Picking the right corner rounding end mill starts with knowing what the job needs. Machinists should think about the material, the shape of the part, and how smooth the finish should be. Each thing changes which tool is best and how the job turns out. Here are some steps to help match the tool to the job:

Check if the material is hard or rough. Harder materials need stronger coatings like TiAlN or diamond.

Look at the shape of the part. Use a corner radius end mill for strong corners and smooth edges.

Think about the finish you want. More flutes make a smoother finish. Fewer flutes cut faster.

Make sure the tool fits the machine’s power and accuracy.

Think about how many parts you need to make. If you have a lot, use tools that last longer.

Pick coatings that work with the material and how you will cut.

Set the speed and feed for the material, tool, and number of flutes.

Hold the workpiece tight and plan the tool path for good results.

A small corner radius is best for parts that need strong, smooth edges. Bull nose end mills help make smooth changes and help the tool last longer, especially in tough corners. Machinists should always pick the right corner radii and cutter size for the job to get the best finish.

Budget Considerations

How much money you have matters when picking tools. Shops need to balance price, how well the tool works, and how nice the finish looks. Expensive end mills work best on new, strong machines and for jobs that need very close sizes. Cheaper tools are good for old machines or jobs that do not need perfect sizes.

Shops can get better results by changing speeds, feeds, and tool paths, even with cheaper tools. Picking the right corner radii and pilot diameter gives strong, smooth edges and saves money.

Tips for Perfect Finishes

Image Source: pexels

Setup and Tool Holding

Setting up the machine and holding the tool right is very important for good results. Operators should do these things:

Hold the workpiece tight so it does not move or bend.

Line up the corner rounding end mill with the path for accurate cuts.

Pick a tool that is the right length and can reach the area.

Use strong tool holders to stop shaking and keep quality high.

Check and adjust the milling machine often for accurate paths.

Add coolant or oil to keep things cool and help chips move away.

Plan how the tool will move, especially in corners or tricky shapes.

Make more than one pass on hard materials or big radii to protect the tool.

End with a light pass to get the smoothest finish.

Try climb milling when you can for better results.

Watch the process as it happens to spot problems fast.

Look at finished parts to make sure they are correct.

A helical flute design moves chips away fast and lowers cutting force. This design helps remove metal better and gives a smoother finish, especially when working quickly.

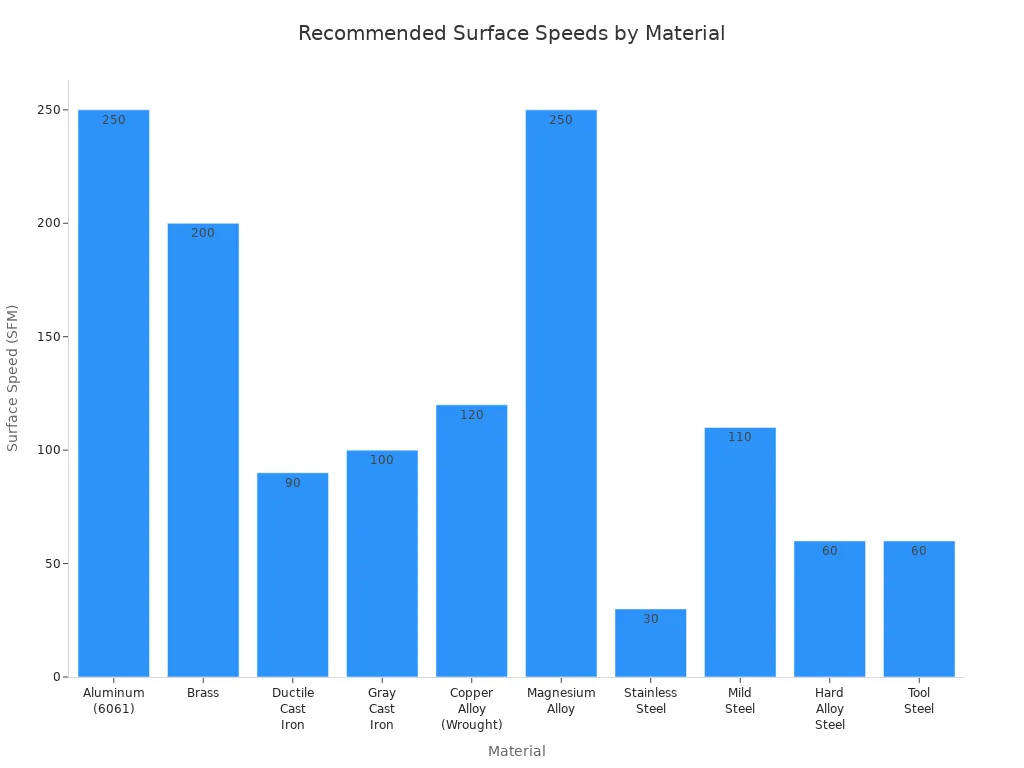

Speeds and Feeds

Picking the right speeds and feeds helps the tool last and makes the finish look good. The table below shows the best surface speeds for HSS end mills in different materials:

Material | Recommended Surface Speed (SFM) for HSS End Mills |

Aluminum (6061) | 250 |

Brass | 200 |

Ductile Cast Iron | 90 |

Gray Cast Iron | 100 |

Copper Alloy (Wrought) | 120 |

Magnesium Alloy | 250 |

Stainless Steel | 30 |

Mild Steel | 110 |

Hard Alloy Steel | 60 |

Tool Steel | 60 |

Operators should change feed rates for curves or corners to keep chip load even. Using the average diameter helps set the right spindle speed. Matching speeds and feeds to the tool and material stops overheating and helps the tool last longer.

Maintenance

Taking care of corner rounding end mills keeps them working well:

Pick the right end mill for each job.

Use cutting settings that fit the material.

Handle tools gently to stop chipping.

Clean and sharpen end mills often to keep them working well.

Doing regular maintenance, handling tools carefully, and storing them right helps tools last longer and gives good results every time.

Unflared Corner Rounder Insights

Design Benefits

An unflared corner rounder makes a full, smooth curve on the edge of a part. This tool is best when you need a complete curve with no breaks. Machinists pick this tool for jobs that cannot have a missing or flat spot on the edge. The unflared design lets you control the edge very well. This is important for jobs where every detail must be perfect.

But using this tool takes more care. The machinist must line up the tool just right and hold the part tightly. Even a small mistake can make steps or cuts that are too deep. The pilot diameter matters too. A bigger pilot gives more strength but can slow things down. A smaller pilot is faster but may not be as steady.

Note: Unflared corner rounders need careful setup, but they give a perfect, full curve when used right.

The table below shows some limits and things to think about:

Limitation/Consideration | Explanation |

Precise Setup Required | Needs careful alignment to avoid steps or over-cuts. |

Sensitivity to Runout and Vibration | Even minor vibration can cause defects. |

Pilot Diameter Impact | Affects tool strength and clearance, especially in tight spaces. |

Material Compatibility | Harder materials may need special coatings or more flutes. |

Machine and Workpiece Setup | Secure clamping and alignment are essential for accuracy. |

Setup Time vs. Radius Completeness | Full radius requires more setup time compared to flared tools. |

Use Cases

Machinists use the unflared corner rounder when a full curve is very important. For example, airplane and medical parts often need smooth, perfect edges with no flat spots. This tool is the best pick when the job does not allow any missing curves. In these cases, the unflared tool helps the part meet strict rules.

Flared corner rounders are better if a small step or not a full curve is okay. Flared tools are faster and easier to set up. But they do not give the same perfect curve as the unflared tool.

Machinists must decide if they want a perfect curve or a faster, easier setup.

Harvey Tool, Maritool, Niagara Cutter, Hiboo Tools, and Micro 100 are known for making tools that are strong and give smooth finishes. Machinists get better results when they pick coated end mills for hard materials. They also do edge work, like polishing with diamond abrasive wheels. These steps help the tools last longer and make the surface look nicer.

To make things even better, machinists can try EDM methods or read guides about how to design parts and pick materials. These ideas help make corners smoother and give every project a more professional look.

FAQ

What is the difference between flared and unflared corner rounding end mills?

Flared end mills make the edge blend smoothly. Unflared end mills cut a full, round curve. Flared tools are easier to set up. Unflared tools need more care but give a perfect curve.

How do coatings affect tool performance?

Coatings like TiAlN or AlTiN make tools harder and tougher. These coatings help tools last longer and make smoother finishes. Shops pick coated tools for hard jobs or fast cutting.

When should machinists choose carbide over high-speed steel?

Carbide end mills last longer and do not wear out fast. Machinists use carbide for hard materials or lots of work. High-speed steel is good for soft materials and cheaper jobs.

How can machinists prevent tool chipping?

Tip: Pick the right speed and feed. Hold the workpiece tight. Use the best tool material and coating. Take light finishing cuts. Check and care for the tool often.

What is the best way to select the right corner radius?

Machinists match the corner radius to the part’s shape. A bigger radius makes the edge stronger and smoother. A smaller radius gives more detail. Always look at the part drawing before picking the tool.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg