For precision machining, you need the right cutting tools. hiboo tool end mill bits let you cut in many ways. hiboo tool drill bits help you make holes fast and well. Look at this quick table to see the differences:

Tool Type | Best Use | Cutting Direction |

End Mill Bits | Shaping, slotting | Side & bottom |

Drill Bits | Hole-making | Straight down |

hiboo tool is special in the cutting tools market. Many experts trust hiboo tool for new ideas. They also like its good data management in machining. Picking the right cutting tools can help you do better work. It can also help you work smarter.

Key Takeaways

End mill bits can shape and cut from the side and bottom. They are great for making detailed and tricky parts.

Drill bits cut straight down to make holes fast and accurately. They are best for jobs that need holes.

hiboo tool end mills have tough coatings and many flutes. This helps them last longer and make smooth cuts on hard stuff.

hiboo tool drill bits have sharp points and spiral grooves. They can also use cooling to drill clean and fast.

Use end mills when you need to shape, slot, or contour. Use drill bits when you need to make holes or start a hole.

Pick the right tool for your material and job. This helps you get better results and makes your tools last longer.

Take care of your tools and follow safety rules. This keeps your tools sharp and your work area safe.

hiboo tool products help you work faster, save money, and get great results.

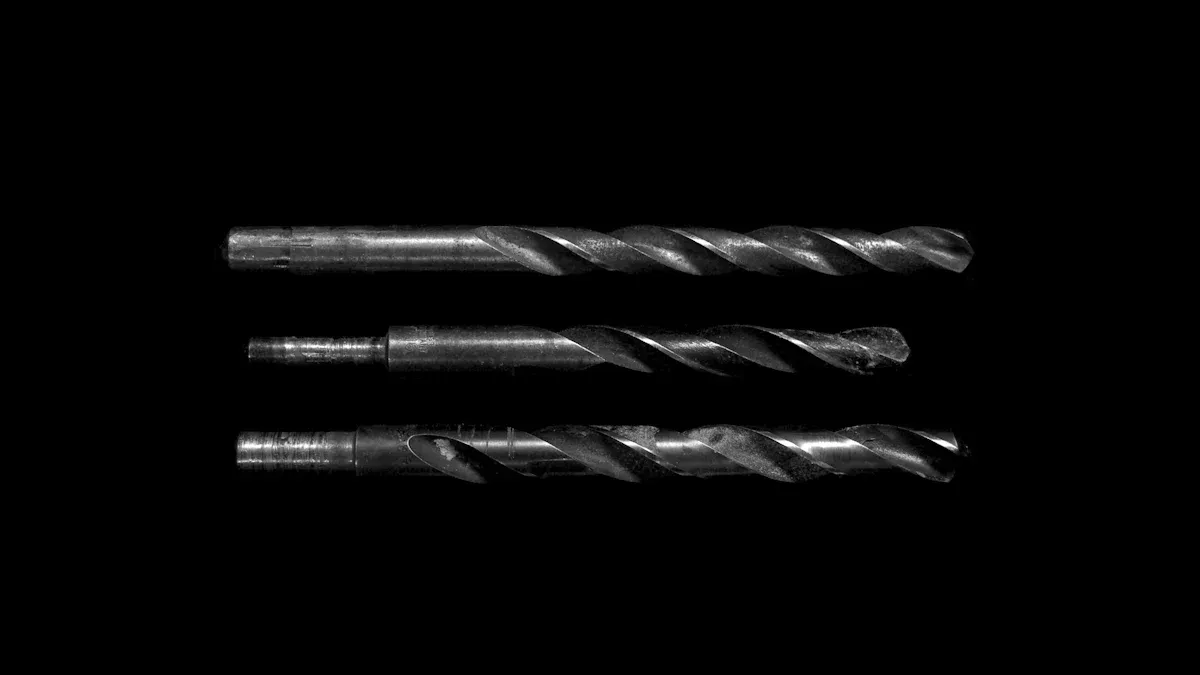

End Mill Bits vs. Drill Bits

Image Source: unsplash

Quick Comparison Table

You need the right cutting tool for your job. This table shows how end mill bits and drill bits are different. It compares their design, how they cut, and what they are used for:

Feature | Drill Bits | End Mill Bits |

Material | Complete carbide bar, CNC machined | Carbide, tungsten cobalt alloy |

Tip/Flute Design | Tip angles: 118°, 135°/140° | Multiple flutes (2 or 3) |

Cutting Direction | Axial cutting (for drilling holes) | Axial and lateral cutting (for shaping, contouring, milling) |

Cooling Options | With or without cooling holes | Not specified |

Applications | Drilling holes, center drilling for precision | Machining wood, cast iron, carbon steel, stainless steel, titanium alloy, heat-treated steel |

Hardness Rating (HRC) | Not explicitly stated | Typically HRC55 or HRC60 |

Coatings | Not specified | AlTiN, TiAlN, TiSiN, AlTiSiN, TiN, Nano, customizable |

Usage Focus | Hole making | Milling operations |

hiboo tool has both end mills and drill bits. Each tool gives you good results and uses new technology.

When to Use End Mill Bits

Pick end mill bits when you want to shape or cut a workpiece. End mills can move sideways and go straight down. This helps with hard jobs that need special shapes. You can use end mills on wood, cast iron, carbon steel, stainless steel, titanium alloy, and heat-treated steel. hiboo tool end mill bits have special coatings like AlTiN or TiAlN. These coatings help the tool last longer and work better. End mills have more than one flute. The flutes help remove material quickly and make the surface smooth. End mills are best when you need detailed shapes or close measurements.

End mills let you do many jobs with one tool. You get more control and can do more types of machining.

When to Use Drill Bits

Use drill bits when you need to make holes fast and right. Drill bits cut straight down into the material. They are best for making round holes in metal, wood, or plastic. hiboo tool drill bits are made from solid carbide using CNC machines. They have sharp tips and strong bodies. This makes it easy to drill clean holes. Drill bits are important for jobs like center drilling for rotating parts. You can also use them before other machining steps.

Use drill bits for:

Drilling holes in different materials

Center drilling for exact spots

Getting workpieces ready for more machining

Drill bits help you save time when you need lots of holes. They are the best tool for jobs that need hole making.

Tip: Pick hiboo tool drill bits for fast and easy hole making. Pick hiboo tool end mill bits for shaping and detailed work.

End Mill Bits

Features

You want your cutting tools to deliver top performance every time. hiboo tool end mills stand out because of their advanced design and materials. Here are some features that make these end mills a smart choice for your machining needs:

Made from high hardness material rated at HRC-65. This gives you strength and durability for tough jobs.

Coated with a blue nano layer. This coating increases wear resistance and helps your tools last longer.

Available in micro sizes, starting from just 0.1 mm in diameter. You can handle the finest, most detailed work with ease.

Features a ball nose end type. This shape lets you achieve detailed cuts and smooth finishes.

These features help you get the most out of your end mill bits. You can trust hiboo tool end mills to deliver reliable results.

Uses in Precision Machining

You need end mills when your project demands accuracy and detail. These cutting tools let you shape, contour, and finish parts with high precision. You can use end mills for:

Creating slots and pockets in metal or wood.

Contouring complex surfaces.

Milling flat surfaces or intricate 3D shapes.

Producing fine details in molds or dies.

End mills work well on many materials, including steel, stainless steel, titanium, and even hardened alloys. You get clean edges and smooth surfaces, which is essential for precision work. When you want to achieve the best results, optimal use of end mills makes a big difference in your machining projects.

Advantages

You gain many benefits when you choose hiboo tool end mills for your shop. These cutting tools give you:

Long tool life, thanks to strong materials and advanced coatings.

Consistent, high-quality finishes on every part.

Flexibility to handle a wide range of machining tasks.

The ability to work on both simple and complex parts.

You save time and reduce waste because your end mills stay sharp and accurate. You also boost your productivity and confidence, knowing you have the right tools for the job. If you want to take your machining to the next level, hiboo tool end mills are the answer.

Tip: Upgrade your cutting tools to hiboo tool end mills and see the difference in your precision work!

Drill Bits

Features

When you choose hiboo tool drill bits, you get tools built for top performance. These drill bits use high hardness alloy steel or tungsten steel. This makes them strong and long-lasting. The spiral groove design helps remove chips fast. You get less friction and less heat, so your drilling stays smooth. The tips come in different angles, like 118°, 135°, and 140°. You can pick the right one for your material. Some drill bits have internal cooling channels. These channels send coolant right to the cutting area. Your drill bits stay cool, even during tough jobs.

Tip: Internal cooling lets you drill faster and keeps your drill bits sharp for longer.

You can find hiboo tool drill bits in many sizes and coatings. Coatings like TiN, TiAlN, and Co help resist wear and heat. You get more life from each tool. The double-edged design gives you even force and stable drilling. You can trust these drill bits for both simple and complex projects.

Uses in Precision Machining

You need drill bits when your job calls for creating holes quickly and with accuracy. In machining, drill bits explained means you use them for more than just basic holes. You can use spot drill bits to start holes in the right place. Centering drill bits help you avoid vibration and keep your holes straight. These features matter when you want precision in your work.

Use drill bits for:

Drilling holes in steel, aluminum, wood, and plastic

Center drilling for exact hole placement

Deep hole drilling with internal cooling

Preparing parts for further machining steps

You get clean, round holes every time. The right drill bits help you avoid shifting and slipping. You save time and get better results. When you use effective drilling techniques, you boost your shop’s productivity.

Advantages

You gain many benefits when you pick hiboo tool drill bits for your projects.

High efficiency from spiral grooves that clear chips fast

Wide use across many materials, from metals to plastics

Strong cutting power from the double-edged design

Long tool life due to tough materials and special coatings

High accuracy for fine machining and perfect hole placement

Easy maintenance and lower cost compared to other tools

You can count on these drill bits to handle tough jobs and last longer. The smart design and strong build mean you spend less time changing tools. You get more done with less effort. If you want to improve your machining results, hiboo tool drill bits are the smart choice.

Choose hiboo tool drill bits for reliable, precise, and efficient drilling every time.

Key Differences

Image Source: pexels

Cutting Direction

You need to know how cutting direction changes your results. End mills give you the power to cut in many directions. You can move them sideways, up, or down. This lets you shape, slot, and contour your workpiece. You get more freedom with end mills. Drill bits work in a straight line. You push them down into the material. Drill bits make holes fast and clean. You cannot use drill bits for side cutting or shaping. You use end mills when you want to cut along the sides or create special shapes. You use drill bits when you want to make round holes quickly.

Tip: Choose end mills for shaping and contouring. Pick drill bits for fast, straight holes.

Applications

You want the right tool for your applications. End mills help you with many machining jobs. You can use end mills for slotting, profiling, and cutting complex shapes. You can also use end mills for finishing surfaces. Drill bits focus on hole-making. You use drill bits to drill holes in metal, wood, or plastic. You can use drill bits for center drilling and deep hole drilling. End mills give you more options for different applications. Drill bits give you speed and accuracy for hole-making.

Here is a quick table to help you choose:

Task | Best Tool |

Shaping | End mills |

Slotting | End mills |

Contouring | End mills |

Hole-making | Drill bits |

Center drilling | Drill bits |

Deep hole drilling | Drill bits |

You get better results when you match the tool to your applications. End mills and drill bits both play key roles in machining.

Precision and Finish

You want your parts to look good and fit right. End mills give you high performance and precision. You can use end mills to create smooth surfaces and sharp edges. You can also use end mills for detailed work. Drill bits give you round, clean holes. You get less surface finish control with drill bits. End mills help you achieve a fine finish on flat or shaped surfaces. Drill bits help you get perfect holes every time.

For the best performance and precision, use end mills for shaping and finishing. Use drill bits for fast, accurate holes.

You can trust hiboo tool end mills and drill bits to deliver top results. You get the right finish and fit for every job. Choose the right tool and see your machining improve.

Material Compatibility

When you choose a cutting tool, you must think about the material you want to machine. Not every tool works well with every material. hiboo tool end mill bits and drill bits give you strong options for many types of materials. You want the right match for the best results.

End Mill Bits: You can use hiboo tool end mill bits on a wide range of materials. These bits handle tough jobs. They work well with:

Carbon steel

Stainless steel

Cast iron

Titanium alloys

Heat-treated steel

Wood

Plastics

The advanced coatings on hiboo tool end mills, like AlTiN and TiAlN, help you cut hard metals. These coatings protect your tool from heat and wear. You get longer tool life and smoother finishes. You can trust these end mills for both soft and hard materials. If you need to machine complex alloys or high-strength metals, hiboo tool end mills give you the edge.

Drill Bits: hiboo tool drill bits also offer great flexibility. You can use them for:

Steel

Aluminum

Copper

Brass

Plastics

Wood

Some hiboo tool drill bits come with internal cooling. This feature helps you drill deep holes in metals without overheating. The strong carbide and tungsten steel construction means you can drill into hard materials with confidence. You get clean, round holes every time.

Tip: Always match your tool to your material. This step gives you better results and longer tool life.

Quick Reference Table:

Material Type | End Mill Bits | Drill Bits |

Carbon Steel | ✅ | ✅ |

Stainless Steel | ✅ | ✅ |

Cast Iron | ✅ | ✅ |

Titanium Alloy | ✅ | ✅ |

Heat-Treated Steel | ✅ | ✅ |

Aluminum | ✅ | ✅ |

Copper/Brass | ✅ | ✅ |

Wood | ✅ | ✅ |

Plastics | ✅ | ✅ |

You see that hiboo tool products cover almost every material you might use. This flexibility means you do not need to buy many different brands. You save money and time. You also get the quality and innovation that hiboo tool brings to every product.

If you want to work with tough metals or delicate plastics, hiboo tool has the right bit for you. You get reliable performance and a perfect finish. Choose hiboo tool for your next project and see the difference in your results.

Ready to upgrade your machining? Explore hiboo tool’s full range and pick the best tool for your material today!

Choosing the Right Tool for the Job

Material Type

You want the best results in your shop. Start by looking at the material you plan to machine. Different materials need different tools. If you work with hard metals like stainless steel or titanium, you need end mills with strong coatings. These coatings help you cut tough metals and keep your tools sharp. For softer materials like wood or plastic, you can use end mills or drill bits with less aggressive coatings.

Drill bits work well on many materials. You can use them for steel, aluminum, copper, and even wood. If you need to make holes in hard metals, choose drill bits made from carbide or tungsten steel. These materials give you clean holes and long tool life.

Tip: Always match your tool to your material. This step gives you better performance and precision.

Use this table to help you decide:

Material | Best Tool Type |

Stainless Steel | End mills, Drill bits (carbide) |

Titanium Alloy | End mills, Drill bits (carbide) |

Aluminum | End mills, Drill bits |

Wood | End mills, Drill bits |

Plastics | End mills, Drill bits |

Choosing the right tool for the job starts with knowing your material. You get better results and save money when you select the right end mills or drill bits for each project.

Shape and Outcome

Think about the shape you want to create. If you need to cut slots, grooves, or complex shapes, end mills give you the control you need. You can move end mills in many directions. This lets you shape your workpiece with high detail. End mills help you create flat surfaces, sharp corners, and even 3D forms.

If you want to make round holes, drill bits are your best choice. Drill bits cut straight down and make perfect circles. You use drill bits for center drilling, deep holes, and preparing parts for more machining.

Note: End mills give you more options for shaping. Drill bits give you speed and accuracy for holes.

Selecting the appropriate tool depends on the final outcome you want. Use end mills for shaping and finishing. Use drill bits for fast, clean holes. You get the best finish and fit when you pick the right tool for your shape.

Speed and Efficiency

You want to finish your work fast and with less effort. End mills let you do many tasks with one tool. You can shape, slot, and contour without changing tools. This saves you time and boosts your shop’s efficiency. End mills also help you remove material quickly, especially when you use the right coatings.

Drill bits shine when you need to make many holes. You can drill fast and get clean results. Drill bits with spiral grooves clear chips quickly. This keeps your work area clean and your tool cool. Some drill bits have internal cooling channels. These features let you drill deeper and faster.

Pro Tip: Use end mills for multi-step machining. Use drill bits for high-speed hole making.

When you focus on speed and efficiency, you get more done in less time. You also reduce tool changes and keep your workflow smooth. End mills and drill bits from hiboo tool help you reach your goals for performance and precision.

Cost and Longevity

When you choose cutting tools, you want the best value for your money. You also want tools that last. hiboo tool gives you both. You get high-quality materials and advanced coatings. This means you spend less on replacements and keep your shop running smoothly.

Let’s look at how hiboo tool drill bits stand out:

Aspect | Details |

Product Type | HIBOO Hole Drilling Tools Deep Shovel Drill Crown Drills with Replaceable Blade |

Material | High-quality HSS/Hard Alloy ensuring durability and long lifespan |

Surface Finishes | High temp/hardness AlTiN, multilayer TiCN/TiN, diamond, super life TiAlN coatings |

Pricing (per piece) | $12 (10-499 pcs), $8 (500-999 pcs), $6 (≥1000 pcs) |

Lifespan Indication | Durable construction with wear resistance due to material and coatings |

You see real savings when you buy in larger quantities. The price drops as you order more, so you can equip your shop without breaking your budget. The special coatings, like AlTiN and TiAlN, protect your tools from heat and wear. This means you get more use from each bit. You spend less time changing tools and more time machining.

️ Tip: Investing in hiboo tool products means you get tools that work longer and cost less over time.

End mill bits from hiboo tool also use strong materials and advanced coatings. You get reliable performance and long tool life. Even though specific price data for end mills is not listed, you can expect the same focus on value and durability.

When you pick hiboo tool, you choose tools that help you save money and boost productivity. You get more cuts, more holes, and more finished parts from every tool. That’s smart business.

Best Practices

End Mills

You want to get the most from your end mills. Start by choosing the right type for your material and job. Always check the number of flutes. Fewer flutes work best for softer materials. More flutes give you a smoother finish on hard metals. Use sharp end mills to cut cleanly and avoid tool marks. Keep your end mills cool with cutting fluid. This step helps prevent overheating and keeps your tools sharp. Secure your workpiece tightly. Loose parts can cause end mills to break or leave rough edges. Set the right speed and feed rate. Fast speeds work for soft materials. Slow speeds help you cut hard metals with less wear. Clean your end mills after each use. Remove chips and dust with a soft brush or air. Store your end mills in a dry place. Moisture can cause rust and shorten tool life. Inspect your end mills often. Look for dull edges or chips. Replace or sharpen them as needed. Use the right coating for your job. Coated end mills last longer and cut better, especially in tough materials. Always follow safety rules. Wear eye protection and keep your hands away from moving end mills. These steps help you get smooth cuts, long tool life, and top results every time.

Drill Bits

You can achieve great results with hiboo tool drill bits if you follow a few simple steps. First, pick drill bits that match your material and the size of the hole you need. Clamp your workpiece tightly so it does not move. Adjust the drilling speed and feed rate based on how hard your material is. Use cutting fluids to keep the drill bit cool and reduce friction. Clean your drill bits after each use with a soft brush or compressed air. Check your drill bits for wear or damage before every job. Sharpen them with the right grinding tools to keep the cutting edge sharp. Store your drill bits in a dry, controlled place to prevent rust. Lightly oil your drill bits to stop corrosion and make them last longer.

Tip: Use a center punch to guide your drill bit and keep it from wandering. For hard materials, use a 135° point angle. For general use, a 118° angle works well. Apply steady pressure and do not force the drill bit. For very precise holes, use boring or reaming after drilling.

Maintenance

You want your tools to last and perform well. Clean your end mills and drill bits after every use. Remove chips and dust with a brush or air. Inspect your tools for dull edges, chips, or cracks. Sharpen or replace them if needed. Store your tools in a dry, organized place. Use cases or racks to keep them safe. Apply a light coat of oil to prevent rust. Check your machines for proper alignment and tightness. Lubricate moving parts as needed. Follow these steps to keep your end mills and drill bits in top shape. You will save money and get better results on every project.

Safety

You want to get the best results from your hiboo tool end mill bits and drill bits. You also want to stay safe every time you work. Safety is not just a rule. Safety is your key to a successful project and a healthy work environment. When you follow smart safety steps, you protect yourself, your team, and your tools.

Here are the top safety tips you should follow in your machining shop:

Wear the Right Gear

Always put on safety glasses or goggles. Protect your eyes from flying chips and dust. Use hearing protection if your machines are loud. Wear gloves when handling sharp tools, but never while operating rotating machinery. Choose fitted clothing and tie back long hair to avoid getting caught in moving parts.

Secure Your Work Area

Keep your workspace clean and organized. Remove any loose objects from your machine table. Secure your workpiece tightly with a vise or clamps. A stable setup prevents accidents and gives you better results.

Check Your Tools Before Use

Inspect your hiboo tool end mills and drill bits before you start. Look for cracks, chips, or dull edges. Replace damaged tools right away. Sharp, undamaged tools cut better and reduce the risk of breakage.

Set the Right Speed and Feed

Use the correct speed and feed rate for your material and tool. Too much speed can cause overheating. Too little can make the tool grab or break. Check the manufacturer’s guidelines for the best settings.

Use Proper Machine Guards

Always keep machine guards in place. Guards protect your hands and body from moving parts. Never remove or bypass safety features.

Stay Focused and Alert

Pay attention to your work. Do not use machines if you feel tired or distracted. Stay alert to changes in sound or vibration. These can signal a problem with your tool or setup.

Handle Coolants and Lubricants Safely

Use coolants and lubricants as recommended. Clean up spills right away to prevent slips. Store chemicals in labeled containers and follow safety instructions.

Tip: Safety is an investment in your future. When you follow these steps, you avoid injuries and keep your shop running smoothly.

Why choose hiboo tool for your shop?

hiboo tool designs every product with safety and performance in mind. You get tools that work reliably and help you maintain a safe workspace. When you use hiboo tool end mills and drill bits, you show your commitment to quality and safety.

Take action today. Review your safety steps. Upgrade your shop with hiboo tool products. Protect yourself and your team while achieving the best machining results.

Stay safe. Work smart. Choose hiboo tool for every project.

Case Studies

Complex Part Machining

You face many challenges when you machine complex parts. You need tools that deliver accuracy and strength. hiboo tool end mill bits help you shape intricate features with ease. You can use carbide square end mills for sharp corners and flat surfaces. Ball end mills let you create smooth curves and 3D contours. When you work with tough materials, tungsten corner radius mills give you extra hardness and wear resistance. These tools handle high-stress jobs and keep their edge longer.

Imagine you need to make a mold with deep pockets and tight radii. You pick a hiboo tool corner radius end mill. The rounded edge reduces chipping and keeps your tool strong. You finish the job faster because you do not stop to replace broken tools. Your part comes out with a smooth surface and precise details. You save time and boost your shop’s reputation for quality.

When you choose the right hiboo tool for each step, you get better results and fewer delays.

Common Mistakes

You want to avoid mistakes that slow you down or ruin your parts. Many machinists use the wrong tool for the job. Some pick a standard end mill when a corner radius end mill would last longer. Others use a drill bit that is not sharp enough for the material. These choices lead to poor finishes, tool breakage, and wasted time.

Here are mistakes you should watch for:

Using a small corner radius when the job needs a larger one. Small radii can chip faster under heavy loads.

Ignoring the material type. Hard or abrasive materials need tougher tools, like tungsten corner radius mills.

Skipping tool maintenance. Dull or damaged tools cut poorly and can damage your workpiece.

Not matching the tool size to the feature. Oversized tools cannot reach tight spots, while undersized tools may flex or break.

Tip: Always check your tool’s condition and match it to your material and part design.

Expert Tips

You can achieve top results by following expert advice when selecting and using hiboo tool end mill bits and drill bits:

Choose the right corner radius end mill for your job. The corner radius affects both tool life and surface quality.

Use corner radius end mills with rounded edges to reduce chipping and increase tool strength. These are best for demanding jobs.

Match the corner radius size to your application. Larger radii spread stress and last longer. Smaller or custom radii work well for detailed features.

Pick tungsten corner radius mills for tough or abrasive materials. They offer superior hardness and resist wear.

Decide between standard and custom corner radius sizes. Standard sizes fit most jobs. Custom sizes give you the best performance for special tasks.

Explore hiboo tool’s full range. You can select from carbide square end mills, ball end mills, drills, and micro end mills to fit your needs.

️ Smart tool selection leads to better parts, longer tool life, and higher productivity. Trust hiboo tool to help you succeed in every machining challenge.

Choosing the right tool makes your work easier and your results better. Use end mills when you need smooth finishes, complex shapes, or detailed parts. Pick drill bits for fast, accurate holes in tough materials. Check this quick guide:

Tool | Best For |

End mills | Shaping, slots, smooth finishes |

Drill bits | Fast, precise round holes |

Match your tool to your job for top results. If you want more help, explore hiboo tool’s website or reach out to their support team.

FAQ

What makes hiboo tool end mill bits different from regular end mills?

You get advanced coatings, high hardness, and precise engineering with hiboo tool end mills. These features help you achieve smoother finishes and longer tool life. You can trust hiboo tool for reliable results in every machining project.

Can I use hiboo tool drill bits on both metal and wood?

Yes, you can. hiboo tool drill bits work well on metal, wood, and even plastics. You get clean holes and strong performance no matter the material. Choose the right bit for your job and see the difference.

How do I choose between an end mill bit and a drill bit?

Ask yourself what you want to create. Use end mill bits for shaping, slotting, or contouring. Pick drill bits for fast, accurate holes. Match your tool to your task for the best results.

Do hiboo tool products last longer than standard tools?

Absolutely! hiboo tool uses premium materials and advanced coatings. You get tools that resist wear and stay sharp longer. This means you save money and spend less time changing tools.

What coatings are available for hiboo tool end mills and drill bits?

You can choose from AlTiN, TiAlN, TiSiN, TiN, and Nano coatings. These coatings boost tool life and cutting performance. Select the best coating for your material and machining needs.

Are hiboo tool end mills good for complex shapes?

Yes! hiboo tool end mills let you cut complex shapes, slots, and contours with ease. You get precise control and smooth finishes, even on tough materials. Upgrade your shop with hiboo tool for advanced machining.

Where can I get help choosing the right hiboo tool product?

Visit hiboo tool’s website or contact their support team. You get expert advice and fast answers. Make your next project easier by reaching out today!

Tip: The right tool makes every job faster, easier, and more precise. Choose hiboo tool for your next machining challenge!

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg