Views: 0 Author: Site Editor Publish Time: 2025-11-03 Origin: Site

Image Source: pexels

You can make smooth and exact cuts in cnc machining if you use a ball nose end mill the right way. Pick the best ball end mill for your material and check your setup before you begin. Watch your tool choice, cutting speeds, and workholding to stop problems like bad finishes or tool wear. Hiboo Tools’ Carbide Ball End Mills give you accuracy and last a long time for good results. Follow clear steps and stay away from common mistakes to make your machining process simple and successful.

Pick the right ball nose end mill for your material. This helps you get smooth and accurate cuts. Watch your tool choice, cutting speed, and how you hold your work. This stops common problems when machining. First, shape the material with a rough cut. Then, use a smaller stepover to make the surface smooth. Clean and sharpen your ball nose end mills often. This makes them last longer and work better. Know what ball nose end mills can and cannot do. They work best for finishing and detail jobs. They are not good for removing lots of material fast.

Image Source: pexels

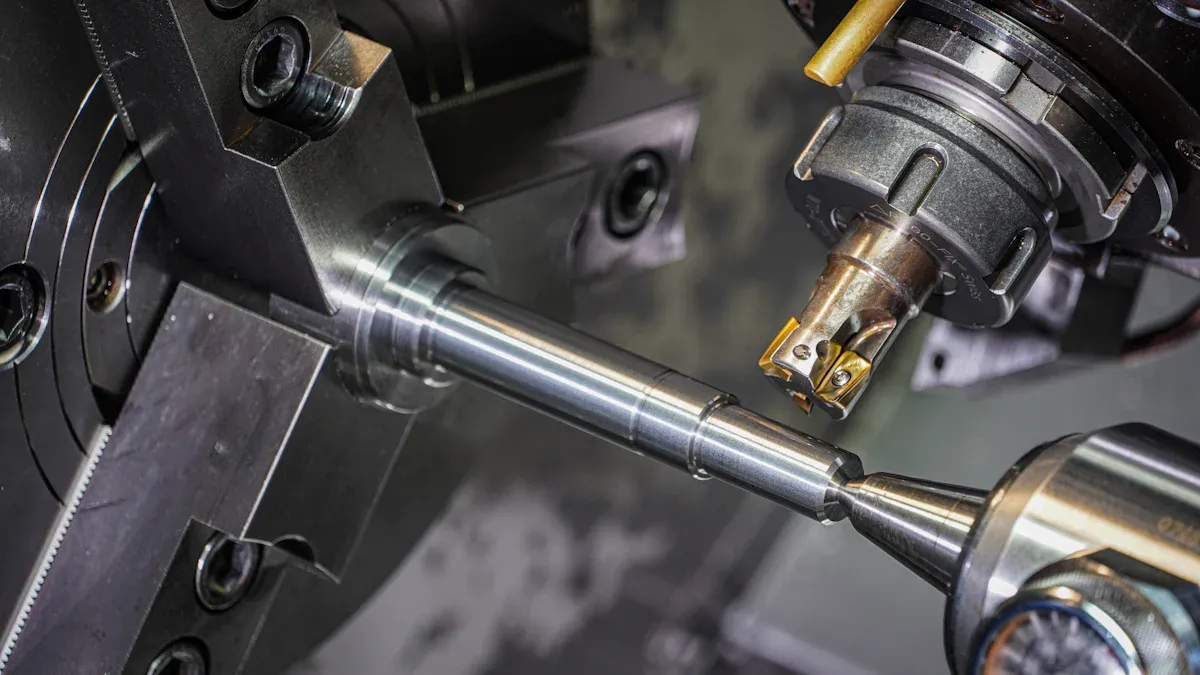

You use a ball nose end mill when you want to create smooth curves and detailed shapes in your cnc projects. This tool has a dome-shaped tip instead of a flat or sharp edge. The rounded end lets you cut 3D contours, reliefs, and complex surfaces with ease. You can see how it compares to other end mills in the table below:

Type of End Mill |

Shape |

Application |

Surface Finish Characteristics |

|---|---|---|---|

Ball Nose End Mill |

Dome-shaped tip |

High-detail contours, relief artwork |

Can lead to scalloping, requires more passes for flat surfaces |

Flat End Mill (Fishtail) |

Flat tip |

Creating flat surfaces, sharp corners |

Produces flat surfaces without scalloping |

Corner Radius End Mill |

Flat bottom, rounded corners |

Combination of flat and ball-nose |

Reduces scalloping, improves surface finish |

You pick a ball end mill when you need to machine molds, dies, or parts with rounded edges. The tip helps you reach tight spaces and create smooth transitions between surfaces.

Hiboo Tools Carbide Ball End Mills stand out because of their strong design and advanced coatings. You get tools made from ultra-fine micro-grain carbide, which means they last longer and resist wear. The special coatings, like TiAlN and AlCrN, help with heat dissipation and chip evacuation. This keeps your tool cool and working well, even on tough materials.

Tip: The geometry of a ball nose end mill matters. The edge radius sets the minimum chipload for effective cutting. The rake angle affects how aggressive the cut feels. The flute design gives space for chips to escape, which helps prevent heat buildup.

Here are the main benefits you get when you use ball-nose end mills for precision cnc machining:

Superior design and construction give you better wear resistance and longer tool life.

You can use them for many tasks, like profiling and contouring, especially when you need a smooth finish.

The ball nose shape lets you cut smoothly and get high-quality finishes, which boosts productivity.

You change tools less often because these end mills last longer.

You save money over time since you need fewer replacements and get more work done.

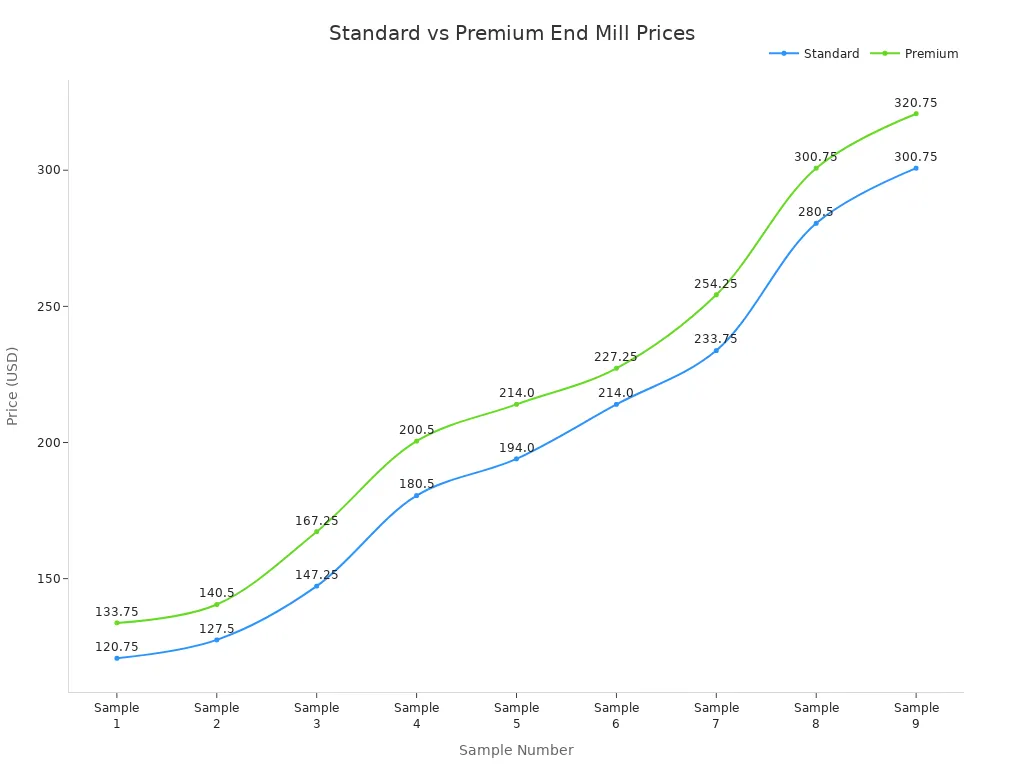

Hiboo Tools offers both standard and premium carbide ball end mill options. Premium tools cost more, but you get extra durability and performance. Check the chart below to see the price difference:

You can choose the right ball nose end mill for your job and budget. Hiboo Tools also provides custom solutions, so you get the exact tool you need for your cnc work.

A ball nose end mill is good for making smooth curves. It helps you finish 3D shapes and curved surfaces. You use it for relief artwork and detailed designs. Mold and die makers use this tool for shaping complex parts. Many industries need ball nose end mills for careful work. You see them in aerospace, cars, and medical jobs where accuracy is important.

Some common ways to use ball nose end mills are:

Machining 3D surfaces

Making molds

Finishing surfaces with care

Creating detailed patterns

Look at the table below to see how different industries use ball nose end mills:

Industry/Application |

Description |

|---|---|

Mold Manufacturing |

Makes complex curves in molds and dies. |

Automotive Components |

Gives smooth finishes to car parts. |

Consumer Electronics |

Used for precise work in electronics. |

Industrial Parts |

Helps make detailed designs and finishes. |

Hiboo Tools’ Carbide Ball End Mills work well for hard jobs. They are very tough and have special coatings to handle heat. These tools last a long time and are great for hard materials. They are perfect for 3D contouring in aerospace and mold making.

Ball end mills have many good points. The round tip helps you finish curved surfaces neatly. You can make detailed shapes and smooth finishes. Hiboo Tools’ ball nose end mills are strong and last a long time. They work well even on hard steel and super alloys.

But there are some downsides. Ball nose end mills do not remove material quickly. You need more time because you take smaller cuts. They are not good for flat-bottomed shapes. If you use them for rough work or deep slots, they may wear out faster.

Here is a table that shows the main downsides:

Limitation |

Description |

|---|---|

Inefficiency in material removal |

Ball nose end mills do not remove material as fast as other types. |

Longer machining times |

You need more time because of smaller cuts. |

Unsuitable for flat-bottomed features |

They are not made for flat-bottomed shapes. |

You can use a tapered ball end mill for deep or angled spaces. This tool helps you reach farther and keeps steady.

Pick ball nose end mills for finishing, shaping, and detailed work. For rough cuts or flat surfaces, choose other tools.

Image Source: unsplash

You want the right ball end mill for your cnc project. Start by looking at the diameter and flute count. A larger diameter gives you more rigidity and lets you cut deeper with less bending. If you need to remove material quickly, pick a bigger tool. For fine details, use a smaller diameter.

The number of flutes matters. Fewer flutes, like one or two, clear chips better and work well with soft materials such as aluminum. More flutes, like four, make smoother finishes but can clog with chips in softer metals. Here is a table to help you choose:

Flute Count |

Impact |

|---|---|

1-2 Flutes |

Better chip clearance, ideal for aluminum and soft materials. |

4 Flutes |

Smoother surface finish, may jam chips in soft materials. |

You also need to think about tool rigidity and how fast you want to remove material:

Factor |

Description |

|---|---|

Tool Rigidity |

Larger diameter means less bending and deeper cuts. |

Material Removal Rate |

Bigger tools remove material faster. |

The flute count affects feed rate, surface finish, and chip removal. More flutes make smoother cuts but less space for chips. If you want a custom tool, Hiboo Tools offers OEM and ODM services. You can get a ball end mill with the right diameter, flute count, and coating for your job. Advanced coatings like TiAlN and AlCrN help your tool last longer and cut better. AlCrN coatings give you more wear resistance and keep the cutting edge sharp, especially in high-speed jobs.

If you need to reach deep or angled spaces, try a tapered ball end mill. This tool helps you keep steady and reach farther into your workpiece.

You need a stable setup for your ball nose end mill. Secure your workpiece tightly so it does not move. Choose the right tool holder for your cnc machine. Here is a table with common tool holders and their advantages:

Tool Holder Type |

Description |

Advantages |

|---|---|---|

CAT Tool Holders |

Sturdy, supports automatic tool change |

Quick changes, good for heavy-duty jobs |

HSK Tool Holders |

Hollow taper, strong internal clamp |

Twice the clamping force, high precision |

BT Tool Holders |

Symmetrical, balanced design |

Stable at high speeds |

Collet Chucks |

Precise holding for small tools |

Fast setup, good productivity |

Heat Shrink Chucks |

Uses heat to grip tool |

High control, precise cutting |

Hydraulic Chucks |

Fluid pressure for clamping |

Less vibration, longer tool life |

Milling Chucks |

Bearing nut for strong grip |

Reliable for tough machining |

When you program your cnc, use smart toolpaths. Tilt the tool 5° to 15° to avoid the center and get a better finish. Set your step-over between 3% and 8% of the tool diameter for smooth surfaces. Use a step-down of 0.05 to 0.2 mm for fine finishes. Keep the tool stick-out short to reduce bending. Pick the right coating for your material. For example, AlCrN works well for tough jobs and keeps your tool sharp.

Tip: Use a two-step finishing process. First, rough out the shape with a larger step-over. Then, finish with a smaller step-over for a smooth surface.

You must set the right speeds and feeds for your ball end mill. If you work with hardened steel, use slower speeds and smaller cuts. Here is a table with recommended rates:

Hardness (Rc) |

SFM |

IPT (inches) |

|---|---|---|

35-45 |

270 |

.0004 - .003 |

45-55 |

200 |

N/A |

55-65 |

70 |

N/A |

The step-over and step-down settings affect your finish and speed. Larger tools let you use bigger step-overs for fast work. Smaller tools need smaller step-overs for detail. Softer materials can handle bigger step-overs. Harder materials need smaller ones to avoid damage. If you want a shiny finish, use a small step-over. If you want speed, use a bigger step-over.

Factor |

Impact on Stepover Performance |

Example Scenario |

|---|---|---|

Tool Diameter |

Bigger tools = bigger step-over for speed; smaller for detail |

10mm tool, 50% step-over = 5mm per pass |

Material Hardness |

Softer = bigger step-over; harder = smaller for safety |

Aluminum, 6mm tool: 10-20% step-over |

Machine Rigidity |

Strong machines = bigger step-over; weak = smaller for accuracy |

Industrial CNC: 50% step-over; desktop: 25% or less |

Note: Always balance quality and speed. Adjust your step-over and step-down to match your needs.

AlCrN coatings help your ball end mill last longer and cut better, especially at high speeds. These coatings resist wear and keep the edge sharp. You get more work done before you need a new tool.

Set up your cnc with the right tool, holder, and program. Choose smart speeds and feeds. Use Hiboo Tools’ custom options and advanced coatings for the best results.

You want your part to look smooth after machining. Ball nose end mills are good for making detailed shapes. But they can leave small bumps called scallop marks. Flat end mills work better for flat areas and finish faster. To get a better finish, keep scallop height low. You do this by making the stepover distance smaller. A smaller stepover means less scallop height. But it takes more time to finish. Using a bigger ball nose end mill helps too. Bigger tools make smaller scallop marks for the same stepover. Try to keep scallop height the same on your whole part. This gives you a smooth look and helps your tool last longer.

Tip: Use a tapered ball end mill for deep or angled spots. It can reach farther and keeps your cuts steady.

You can stop mistakes by planning your toolpaths well. Pick the right tool size for your job. Hiboo Tools Carbide Ball End Mills last longer and work well. You spend less time changing tools and more time machining.

Here is a table with problems and ways to fix them:

Common Problem |

Problem Description |

Solution |

|---|---|---|

Tool breakage |

Tool breaks when cutting hard stuff or deep areas. |

Change feed rate and spindle speed; use good toolpaths; pick strong tool materials. |

Poor surface finish |

Hard to get a smooth look, especially with tricky shapes. |

Use smaller steps for finishing; keep tools sharp; use coolant. |

Vibration and tremor |

Vibration makes the surface rough and wears out tools. |

Hold tools tight; set cutting settings well; use short tools. |

Tools wear quickly |

Tools wear out fast in tough jobs. |

Use strong tools; do not use high feed rates; add coolant or lubricant. |

Poor cutting accuracy |

Parts may need fixing if accuracy is low. |

Check tools often; use smart strategies; keep machines precise. |

When you pick tool diameter, remember bigger tools are more accurate and cut heavier. Smaller tools are good for fine details but bend more. Hiboo Tools uses carbide to cut faster and reduce vibration. This helps you work better and keep your parts precise.

You want your ball nose end mills to last a long time. Taking care of them helps you save money. Clean your end mills after you use them. This removes chips and coolant. Put them away safely so they do not get damaged. Sharpen your tools often. Most carbide ball end mills can be sharpened three to five times before you need a new one. Check your tools for wear and replace them before they break.

Keep your CNC machine in good condition. Make sure oil flows well through sight glasses for spindle lubrication. Clean the way wiper systems and look for oil buildup. Check that oil spreads to all moving parts. These steps help your machine work well and protect your tools.

Hiboo Tools uses strict quality rules. Their ISO 9001 certification means their products are reliable and meet customer needs. You can trust Hiboo Tools to give you good quality and performance.

You might have problems like rough surfaces, tool wear, or chatter when using your CNC machine. Here are some ways to fix these problems:

Balance your tool holders to stop vibration.

Hold your workpiece tight so it does not move.

Use the shortest tool you can to lower bending.

Pick end mills with more flutes for smoother cuts.

Change spindle speed and feed rate for your material.

Change your tool path to push cutting forces into stronger parts.

Try climb milling if regular milling does not work well.

Make sure your tool run-out is within limits.

The main reasons tools wear out early are abrasive wear, flank wear, crater wear, adhesion wear, chipping, thermal cracking, and plastic deformation. Watch for these signs and act fast to stop tool failure.

Hiboo Tools helps you after you buy their products. You get usage guides, technical help, repair services, and regular check-ins.

Service Type |

Description |

|---|---|

Usage Guide |

Step-by-step instructions and operation guides for milling cutters. |

Technical Consultation |

Expert answers to technical questions during use. |

Repair Service |

Fast repair of broken milling cutters to reduce downtime. |

Customer Return Visit |

Regular visits to check if you are happy and solve problems. |

Tip: Doing regular maintenance and fixing problems quickly keeps your CNC jobs running well and helps you get the best results from your Hiboo Tools Carbide Ball End Mills.

You can get smooth and accurate CNC results if you follow simple steps for setting up and using a ball nose end mill. Pick good tools like Hiboo Tools Carbide Ball End Mills because they last longer and make better finishes. Use these ideas to help your machining projects. When you talk to suppliers, think about what you need and which tool type works best, like standard, tapered, or extended-reach ball nose end mills. Keep learning new things and ask trusted suppliers for help so you can do well in CNC machining.

You use a ball nose end mill to create smooth curves and high-detail contours. This tool helps you finish 3D shapes and complex surfaces in your projects.

You should match the ball cutter size and coating to your material. Harder materials need strong coatings like AlCrN. Softer materials work well with fewer flutes and larger diameters.

You can use a ball nose end mill for roughing, but it works best for finishing. Flat end mills remove material faster during the cnc process. Save the ball nose for detailed work.

You should use a small stepover and keep your tool sharp. Clean your tool often. Try a two-step process: rough first, then finish with a smaller stepover for a smooth look.

You need to clean your tool after use and store it safely. Check for wear and sharpen it when needed. Regular care helps your tool last longer and keeps your cuts accurate.