Quick Overview

| Feature | 2 Flute End Mill | 4 Flute End Mill |

| Number of Flutes | 2 | 4 |

| Chip Clearance | Larger chip space | Smaller chip space |

| Cutting Speed | Faster chip removal, suitable for soft materials | Smoother cutting, ideal for hard materials |

| Material Suitability | Aluminum, plastics, softer metals | Steel, stainless steel, harder alloys |

| Finish Quality | Rougher surface finish | Smoother surface finish |

| Feed Rate | Higher feed rate | Lower feed rate but higher rigidity |

| Coolant Access | Better airflow for cooling | Limited airflow, needs coolant |

| Ideal For | Slotting and roughing operations | Finishing operations |

Summary of Pros and Cons

| Type | Pros | Cons |

| 2 Flute End Mill | Excellent chip clearance, great for softer materials, faster material removal | Rougher finish, less rigid |

| 4 Flute End Mill | Better surface finish, longer tool life, more rigid | Less chip space, risk of clogging in soft materials |

Introduction

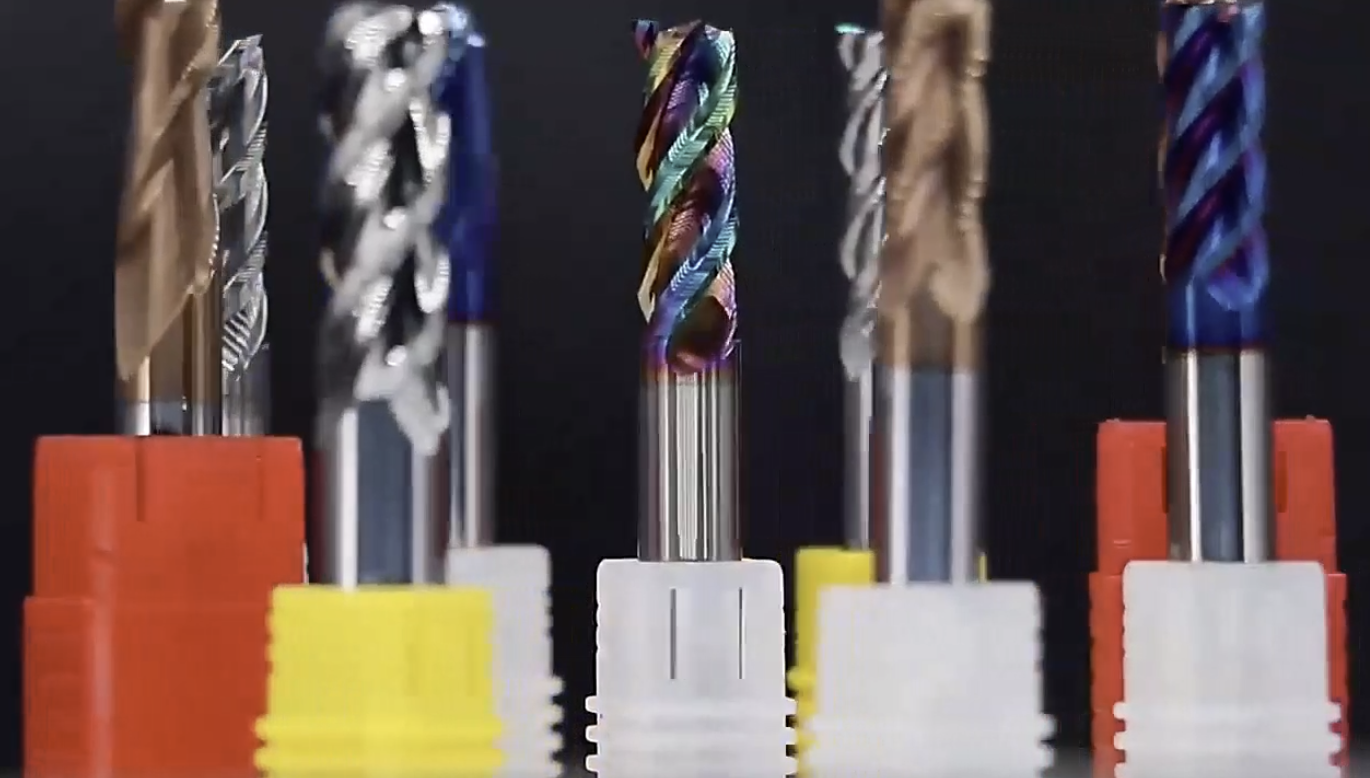

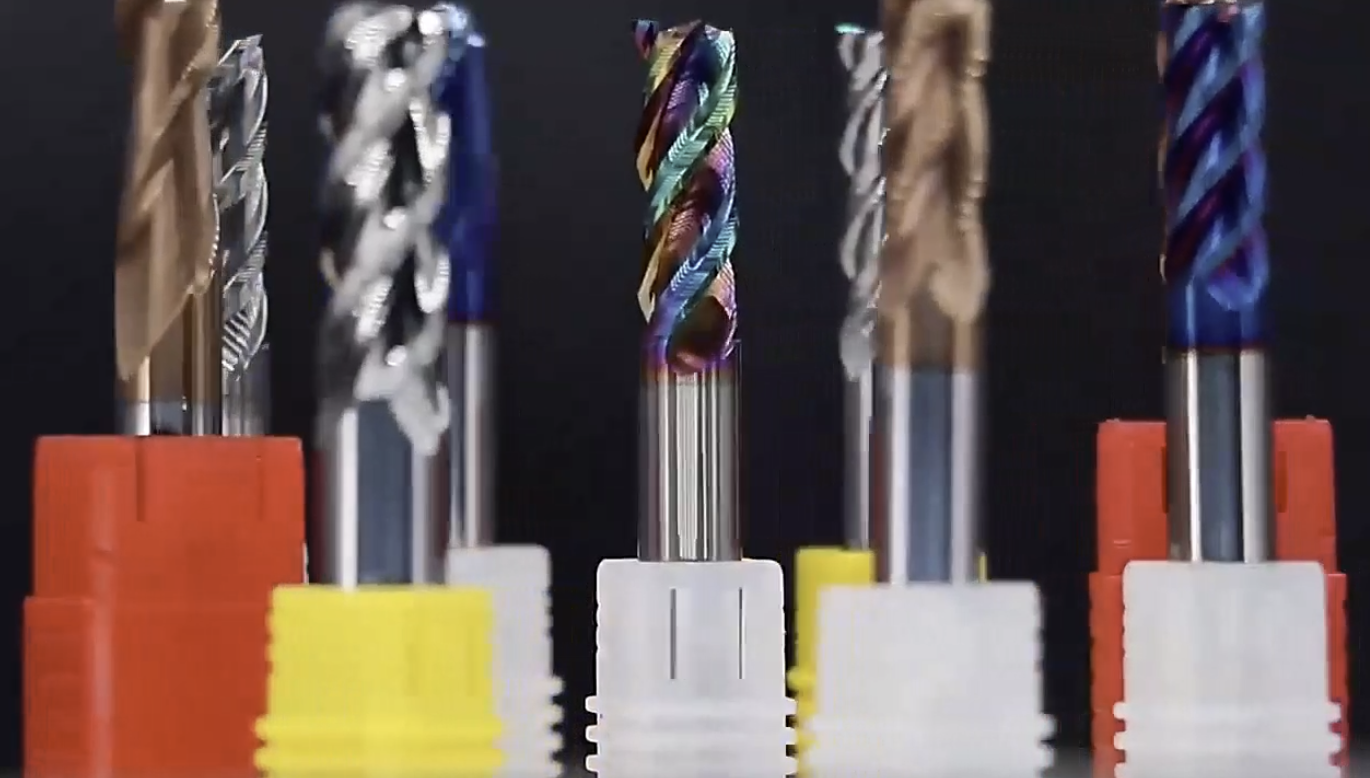

If you’ve ever worked with a CNC machine or done any kind of milling, you’ve probably come across end mills. These are the unsung heroes of the machining world — shaping, cutting, and carving metal and other materials into precise parts. But when you go to pick one, the question always comes up: Should you use a 2 flute end mill or a 4 flute end mill?

Sounds like a small detail, right? Yet this small choice can make or break your machining job. So, let’s dig deep and understand what sets them apart — and more importantly, when to use each one.

What Is an End Mill, Anyway?

Before we jump into flutes, let’s start with the basics.

An end mill is a type of cutting tool used in milling applications. It looks like a drill bit but performs differently. While a drill cuts straight down into material, an end mill can cut in all directions — vertically, horizontally, and even at an angle.

End mills are used for profiling, contouring, slotting, drilling, and finishing. They come in different shapes, coatings, and — you guessed it — flute numbers.

So, what’s a flute?

What Are Flutes on an End Mill?

Imagine spiral grooves twisting along the body of your end mill — those are flutes. They have two main purposes:

Cutting Edge: The sharp edges of the flute slice into the material.

Chip Removal: The space between the flutes allows the cut material (chips) to escape.

The number of flutes affects chip clearance, tool strength, feed rates, and surface finish. This is why the difference between a 2 flute and 4 flute end mill matters so much.

2 Flute End Mill: The Workhorse for Soft Materials

Let’s start with the 2 flute end mill — often the go-to tool for beginners and machinists working with softer materials like aluminum, brass, or plastics.

1. Design and Function

A 2 flute end mill has two cutting edges and two large flute valleys. This design gives the tool plenty of space for chip evacuation, which is crucial when working with materials that tend to gum up or clog.

2. Advantages

Excellent Chip Clearance: With more space between flutes, chips can easily escape, preventing clogging.

Faster Material Removal: You can push the tool harder and take bigger cuts.

Better Cooling: The open design allows more air or coolant to reach the cutting edge, keeping it cooler.

3. Disadvantages

Rougher Finish: Fewer flutes mean fewer cutting edges, resulting in a less smooth finish.

Less Rigidity: With fewer flutes, the tool is slightly weaker and more prone to vibration.

4. Best Applications

In short, the 2 flute end mill is perfect for soft materials and high-speed cutting where you want to move material quickly.

4 Flute End Mill: The Precision Performer

Now, let’s talk about the 4 flute end mill — the precision tool designed for harder materials and finishing passes.

1. Design and Function

With four cutting edges, this tool offers greater rigidity and a smoother cutting action. However, the reduced flute space means less room for chips, making it less suitable for soft or gummy materials.

2. Advantages

Smoother Surface Finish: More cutting edges mean smaller chip sizes and a finer finish.

Higher Strength and Rigidity: The tool can withstand greater pressure and vibration.

Longer Tool Life: The load is shared across more flutes, reducing wear.

Better for Hard Metals: Ideal for cutting steel, stainless steel, and harder alloys.

3. Disadvantages

4. Best Applications

The 4 flute end mill is your go-to tool for precision and finish, especially when working with tougher materials.

2 Flute vs 4 Flute End Mill: Key Differences Explained

Let’s break down the main distinctions between the two types.

1. Chip Removal

This is the biggest factor.

2 flute end mills provide more room for chips to clear out, which keeps things cool and prevents clogging.

4 flute end mills, with their smaller flute spaces, can struggle with chip removal — especially in soft metals.

2. Feed Rate and Speed

3. Surface Finish

2 flute end mills produce rougher surfaces.

4 flute end mills deliver smoother, more refined finishes.

4. Tool Rigidity

More flutes mean greater rigidity. The 4 flute end mill resists deflection and vibration better, leading to tighter tolerances and longer life.

5. Material Type

2 flute end mills: Aluminum, brass, and plastics

4 flute end mills: Steel, stainless steel, cast iron, titanium

Why Does the Number of Flutes Matter So Much?

Think of flutes like lanes on a highway.

If there are too few, traffic (chips) moves freely — but each car (cutting edge) has to work harder.

If there are too many, you get traffic jams (chip buildup), but each car carries a lighter load.

The trick is to choose the right “traffic pattern” for your material and operation.

Choosing Between 2 Flute and 4 Flute End Mills

So, when should you use each one? Here’s a quick guide:

Use a 2 Flute End Mill When:

Working with soft or sticky materials (like aluminum or plastic)

You need fast material removal

You’re doing slotting or deep cuts

Cooling and chip evacuation are top priorities

Use a 4 Flute End Mill When:

You’re machining hard materials (like steel or cast iron)

You need a fine surface finish

You’re doing finishing operations

Tool rigidity and precision matter more than speed

Material and Coating Considerations

Flutes are just one part of the equation. Material and coating can make a world of difference too.

1. Tool Material

High-Speed Steel (HSS): Affordable and good for general-purpose milling.

Carbide: Harder, more heat-resistant, and ideal for high-speed operations.

Cobalt: Great for tougher materials like stainless steel.

2. Coating Types

TiN (Titanium Nitride): Increases wear resistance.

TiAlN (Titanium Aluminum Nitride): Handles higher temperatures.

DLC (Diamond-Like Carbon): Perfect for aluminum — reduces sticking.

Common Mistakes to Avoid

Even seasoned machinists can trip up when choosing or using end mills. Here are some things to watch out for:

Using 4 flute end mills in aluminum: Chips get stuck and ruin the surface.

Pushing 2 flute end mills too hard: They can deflect and chatter.

Ignoring coolant: Especially critical for high-speed or deep cuts.

Wrong speeds and feeds: Always adjust based on flute count and material type.

Pro Tips for Getting the Best Results

Match the flute count to your material. Soft materials = fewer flutes; hard materials = more flutes.

Use coolant wisely. Helps with heat dissipation and chip removal.

Monitor chip color and shape. Blue chips mean overheating; long chips mean poor evacuation.

Invest in quality carbide tools. They last longer and perform better.

Try variable flute designs. They reduce vibration and improve finish.

Advanced Flute Variations: Beyond 2 and 4

While 2 and 4 flutes are the most common, modern machining has expanded the range.

3 Flute End Mills: A great compromise between chip clearance and rigidity.

5+ Flute End Mills: Designed for ultra-smooth finishes on hard metals.

Variable Flute End Mills: Reduce vibration and increase tool life.

These advanced options give machinists even more control over performance and finish.

End Mill Maintenance and Longevity Tips

Your end mill’s life depends heavily on how you treat it. Here’s how to make it last longer:

Clean after every use. Remove chips and debris.

Avoid overheating. Use coolant or air blast.

Inspect regularly. Look for wear or chipping on edges.

Store properly. Keep tools dry and organized.

Conclusion

When it comes down to it, the choice between a 2 flute end mill and a 4 flute end mill is all about balance — speed versus precision, chip clearance versus surface finish.

If you’re cutting aluminum or softer materials and want fast chip removal, go for a 2 flute end mill.

But if you’re working on steel and want a smooth, precise finish, the 4 flute end mill is your best friend.

By understanding how flute count impacts performance, you’ll not only improve your machining efficiency but also extend your tool life and achieve higher-quality results.

Final Thoughts

Choosing the right end mill isn’t just about picking a tool — it’s about understanding the science of cutting. Once you master how flutes, material, and coatings interact, you’ll find your machining projects becoming faster, smoother, and far more satisfying.

Because at the end of the day, in milling — as in life — it’s all about finding the perfect balance.

FAQ About End Mills

1. What is an end mill used for?

An end mill is a cutting tool used in milling machines or CNC machining centers to cut materials like metal, wood, or plastic. Unlike a drill bit that only cuts straight down, an end mill can cut in multiple directions — vertically, laterally, and even diagonally. It’s used for profiling, contouring, slotting, drilling, and finishing.

2. What is the difference between an end mill and a drill bit?

The main difference is in cutting direction and design:

A drill bit cuts straight down to make holes.

An end mill can cut sideways and shape the surface of materials.

End mills have flutes and cutting edges along their sides, allowing for more complex shapes and surface finishes.

3. What are flutes on an end mill?

Flutes are the spiral grooves that run along the body of an end mill. They act as:

The number of flutes affects tool performance, surface finish, and chip removal — that’s why choosing between a 2 flute end mill and a 4 flute end mill matters.

4. What’s the difference between roughing and finishing end mills?

Roughing end mills remove large amounts of material quickly. They have serrated edges that break up chips and reduce cutting load.

Finishing end mills are used for the final pass, producing a smooth, accurate surface.

You can think of roughing as carving the shape, and finishing as polishing the details.

5. Can I use a 4 flute end mill for aluminum?

Technically, yes — but it’s not recommended. Aluminum chips are soft and sticky, and 4 flute tools have small flute spaces, which can cause chip clogging and poor surface finish. A 2 or 3 flute end mill is much safer and more efficient for aluminum.

6. What is the best end mill for steel?

For steel, use:

4 flute or more end mills for higher rigidity.

Carbide or cobalt material for heat resistance.

TiAlN or TiCN coatings to withstand higher temperatures.

These features allow smoother cutting and longer tool life in hard materials.

7. What’s the difference between carbide and HSS end mills?

HSS (High-Speed Steel): Affordable and tough, but wears faster. Good for low-speed operations.

Carbide: Harder, heat-resistant, and capable of higher speeds. Best for CNC and precision work.

If you want durability and cleaner finishes, carbide end mills are worth the investment.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg