Choosing the right end mill manufacturer can be the difference between smooth, efficient machining and a frustrating, costly production line. Whether you're in aerospace, automotive, mold-making, medical equipment, or general machining, the quality of your end mills determines your output. And with India’s machining industry growing at record speed, many companies now offer world-class tools at competitive prices.

So, how do you know which brands truly stand out? That’s exactly what this guide answers.

Why Choosing the Right End Mill Manufacturer Matters

Before we go manufacturer by manufacturer, let’s quickly address something crucial—what makes a great end mill manufacturer?

Choosing the right brand ensures:

Think of it like choosing the right tires for your car—yes, all tires look the same, but the performance difference is massive.

Key Factors to Evaluate an End Mill Manufacturer

1. Material Quality

Carbide purity, coating technology, and hardness levels determine real-world performance.

2. Production Technology

Is the company using 5-axis grinders? Automated coating machines? Consistent heat treatment?

3. Product Range

A reliable manufacturer should offer:

4. Consistency & Tolerance Accuracy

Precision machining requires repeatability.

5. Technical Support

Top brands help customers choose the right geometry and troubleshoot operational issues.

Top 10 End Mill Manufacturers in India (2025)

1. Changzhou Hiboo Tools Co., Ltd

Overview

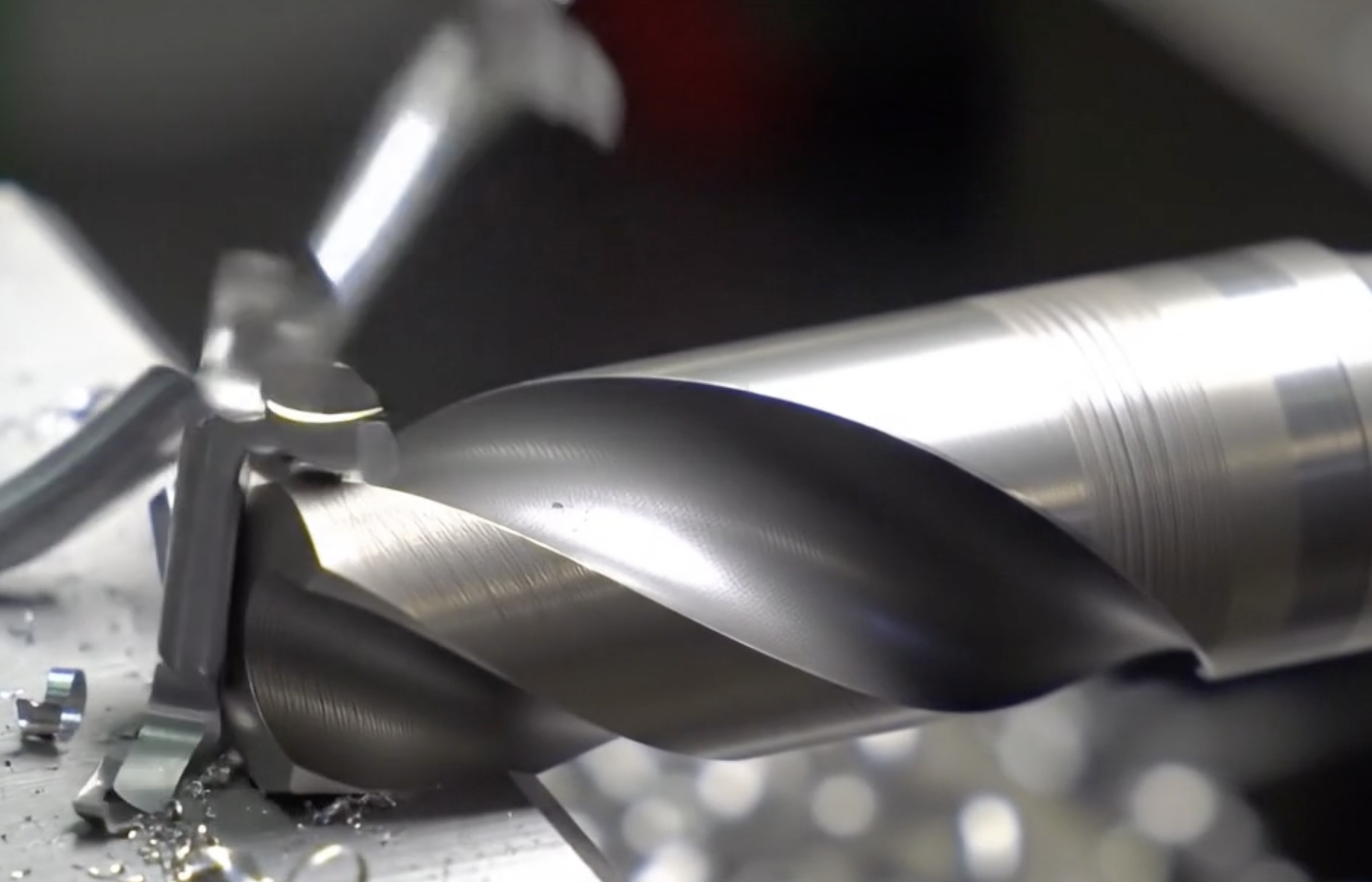

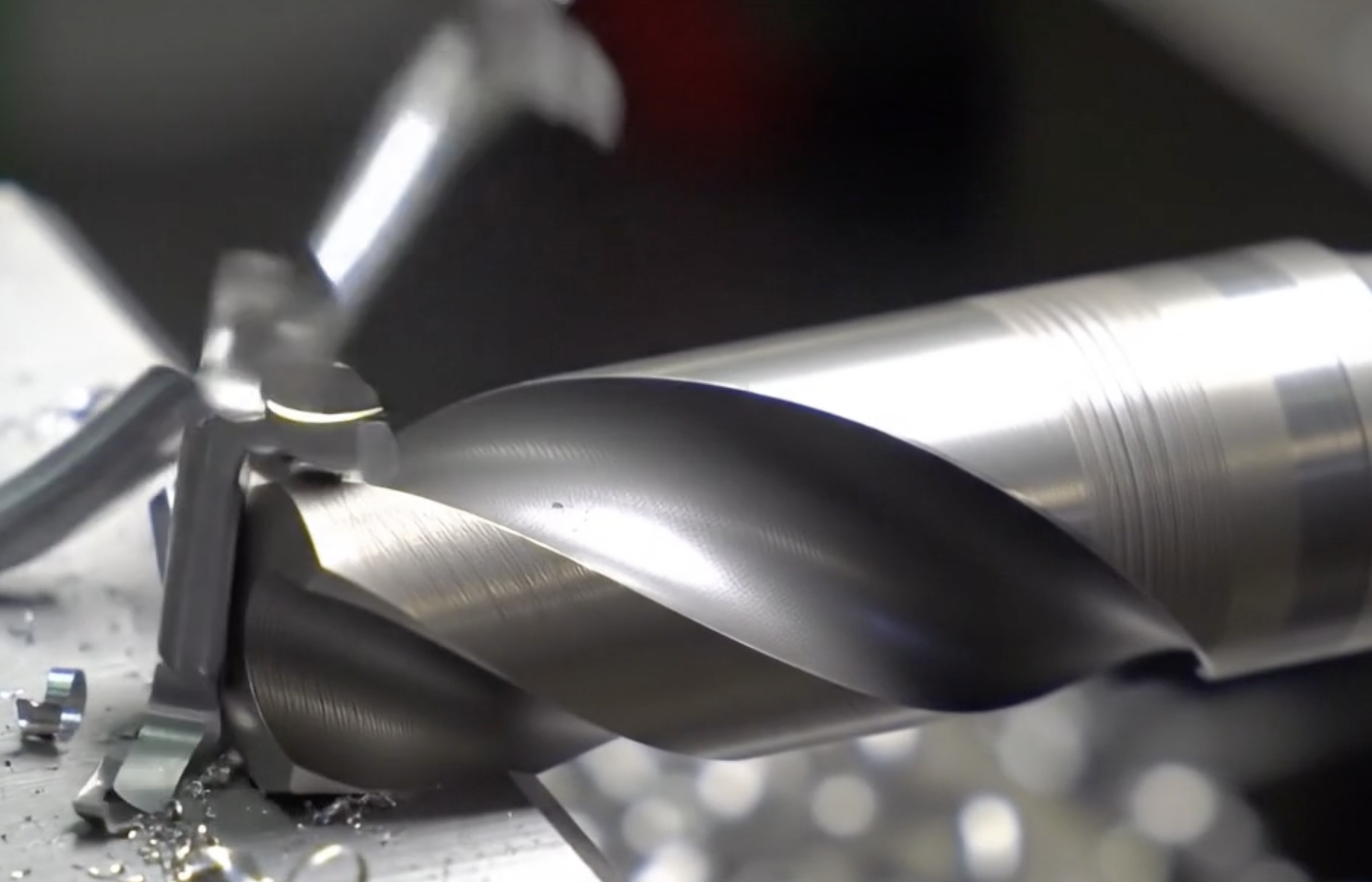

Although headquartered in China, Changzhou Hiboo Tools Co., Ltd is one of the most trusted end mill manufacturers serving the Indian market. With a massive distributor presence across India, Hiboo has become a top choice for machinists seeking high-quality carbide end mills at competitive prices. Their products are widely used in automotive mold manufacturing, aerospace machining, and precision part production.

Strengths

Large selection of solid carbide end mills

Advanced German 5-axis grinding centers

High wear-resistant PVD coatings (AlTiN, TiSiN, AlCrN)

Excellent price-performance ratio

Supports OEM & custom geometry manufacturing

Best Known For

2. Sandvik Coromant India

Overview

A global giant, Sandvik Coromant is one of the most premium cutting tool brands in India. Their focus on precision engineering and research makes them a leader in advanced milling applications.

Strengths

Ultra-high-quality carbide

Proprietary coatings

Advanced geometries for heat-resistant materials

Excellent training & technical support

Popular End Mill Series

CoroMill® Plura

CoroMill® 316

3. Kennametal India

Overview

Kennametal is a trusted name among heavy-duty machining industries, especially aerospace and die-mold.

Strengths

Robust carbide capable of high feed rates

Superior tolerance accuracy

Long tool life, even at high temperatures

Ideal For

Manufacturers requiring durability in stainless steel, titanium, or Inconel milling.

4. Seco Tools India

Overview

Seco is known for its balanced approach—great quality paired with strong affordability. They are especially popular among mid-sized Indian machine shops.

Strengths

Excellent chip evacuation designs

Carbide with predictable wear behavior

Fine surface finishing capability

Best Application Areas

Die & mold

General engineering

Precision machining

5. Iscar India

Overview

Part of the IMC Group, Iscar delivers innovative milling tools with patented geometries.

Strengths

Multi-flute high-feed end mills

Carbide with enhanced toughness

Great for high-speed & dry machining

Standout Feature

Extensive range of indexable milling tools in addition to solid carbide.

6. Mitsubishi Materials India

Overview

Known for their research-driven manufacturing, Mitsubishi offers high-end carbide with exceptional wear resistance.

Strengths

Popular Series

Aluma Series

VQ end mills

7. Kyocera India

Overview

Kyocera tools are engineered with exceptional attention to detail. They’re widely used in CNC machining industries across India.

Strengths

Most Popular Products

8. Guhring India

Overview

Guhring’s German engineering blends well with localized Indian production. Their Indian facilities ensure competitive pricing with premium quality.

Strengths

Specialization

Micro-machining & miniature tool geometries.

9. Yongjin Tools India

Overview

A fast-growing supplier in India, Yongjin offers cost-effective carbide cutting tools for general machining and mold industries.

Strengths

Popular Products

Roughing end mills

2F & 4F square end mills

10. Fullerton India

Overview

Fullerton is known for supplying high-performance solutions to industries requiring tight tolerances.

Strengths

Ideal Industries

Aerospace

Defense

Medical machining

Comparison Table: Top 10 End Mill Manufacturers in India (2025)

| Rank | Manufacturer Name | Core Strength | Best For |

| 1 | Changzhou Hiboo Tools Co., Ltd | High precision, affordability | General machining, molds |

| 2 | Sandvik Coromant | Premium quality & innovation | Aerospace, automotive |

| 3 | Kennametal India | Heavy-duty performance | Hard metals & alloys |

| 4 | Seco Tools India | Balanced quality | SMEs & mid-scale machining |

| 5 | Iscar India | Patented geometries | High-speed operations |

| 6 | Mitsubishi Materials | High wear resistance | Hardened steel cutting |

| 7 | Kyocera India | Stable finishing tools | CNC finishing operations |

| 8 | Guhring India | Precision micro tools | Miniature machining |

| 9 | Yongjin Tools India | Low-cost carbide | General workshops |

| 10 | Fullerton India | High-performance end mills | Critical precision industries |

How to Choose the Right End Mill Manufacturer for Your Needs

1. Identify Your Material

Different manufacturers specialize in:

Aluminum milling

Stainless steel milling

Titanium milling

Hardened steel machining

2. Choose Based on Application

Need roughing?

Go for high-feed mills from Iscar or Kennametal.

Need fine finishing?

Kyocera or Guhring might be better.

3. Budget vs. Performance

Hiboo, Yongjin → Best pricing

Sandvik, Mitsubishi → High-end engineering

Seco, Guhring → Balanced performance

4. Look for Technical Service

Brands that offer coating advice, geometry selection help, and troubleshooting can save you both money and time.

Why Carbide End Mills Dominate the Indian Market

Carbide end mills are preferred because they:

If machining were a race, carbide end mills would be the supercars.

Final Thoughts

Finding the right end mill manufacturer is crucial for achieving precision, productivity, and profitability. India’s cutting tool market in 2025 is stronger than ever, with strong contributions from global leaders and local innovators.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg