Image Source: pexels

Advanced coatings, smart integration, and sustainable practices now shape the aluminum end mill landscape for 2025. These innovations boost machining precision, streamline efficiency, and reduce overall costs. Professionals see significant improvements in tool performance and reliability. Hiboo tools leads the way with cutting-edge solutions in this field.

For those seeking the latest industry advancements, hiboo tools (https://www.hiboo-tools.com) offers valuable resources and proven expertise.

Key Takeaways

Advanced nano-coatings greatly increase aluminum end mills' heat resistance and tool life, allowing faster machining with less wear.

Low-friction coatings like DLC improve chip removal and reduce tool wear, boosting surface quality and cutting speed.

Variable helix tool designs reduce vibration and chatter, enabling smoother cuts and higher machining speeds.

Embedded sensors in end mills provide real-time data on tool health, helping prevent failures and reduce downtime.

Industry 4.0 technologies connect smart tools with CNC machines for automated, precise, and efficient machining processes.

Sustainable practices, including recycled materials and energy-efficient equipment, lower costs and reduce environmental impact.

Custom aluminum end mills tailored for aerospace, automotive, and electronics improve part quality and production efficiency.

Software simulation and turnkey solutions speed up tool design and machining, cutting cycle times and increasing productivity.

Aluminum End Mill Coatings

Image Source: pexels

Nano-Coatings

Heat Resistance

Nano-coatings represent a major leap in aluminum end mill technology. These ultra-thin layers, often measured in nanometers, provide exceptional heat resistance. Manufacturers use advanced materials like AlTiSiN and AlCrN to create coatings that withstand high temperatures during milling. The presence of silicon in these coatings refines the grain structure and increases oxidation resistance. As a result, the tool maintains its hardness and sharpness even under intense heat. This improvement allows machinists to run tools at higher speeds without risking thermal damage.

Tool Life

Nano-coatings also extend the life of aluminum end mills. Studies show that nanocomposite coatings such as AlTiSiN can double tool life compared to uncoated or conventionally coated tools. These coatings form protective films, like Al2O3, on the tool surface. The films reduce wear and prevent the formation of built-up edges. Tools with nano-coatings maintain better surface integrity and deliver consistent results over longer periods. This means fewer tool changes and lower production costs for manufacturers.

Hiboo Tools applies advanced nano-coatings to its aluminum end mill lineup. Their R&D team uses imported CNC grinders and high-quality tungsten steel to ensure each tool meets strict standards. Every tool undergoes precise inspection, guaranteeing long-lasting performance in demanding environments.

Low-Friction Coatings

Chip Evacuation

Low-friction coatings, such as diamond-like carbon (DLC), play a crucial role in efficient chip evacuation. These coatings create a smooth surface on the tool, which helps chips slide away quickly during machining. Fast chip removal prevents clogging and reduces the risk of tool failure. DLC coatings, with friction coefficients as low as 0.01, minimize the chances of aluminum sticking to the tool. This property is especially important in high-speed operations, where chip buildup can halt production.

Wear Resistance

Wear resistance improves significantly with low-friction coatings. DLC and nano-crystalline diamond (NCD) coatings outperform traditional hard coatings like TiN and TiAlN in aluminum machining. They reduce cutting forces and built-up edge formation, leading to better surface quality and longer tool life. For example, carbon-based coatings such as Graphit-iC™ have increased tool life by over 400% in automotive aluminum applications. These coatings also maintain dimensional accuracy by reducing the number of undersized holes.

The following table summarizes the latest coating technologies and their benefits for aluminum end mills:

Coating Type | Application Area | Key Benefits | Best Suited For |

DLC (Diamond-Like Carbon) | Aluminum machining, high-speed ops | Low friction, smooth finish, reduces build-up | Aluminum end mills needing precision and reduced heat |

TiN (Titanium Nitride) | General-purpose HSS tools | Enhanced wear resistance, high hardness, low friction | Softer materials including aluminum, general machining |

Multi-layer Coatings | Extreme machining conditions | Superior wear and heat resistance, friction reduction | High-performance and complex materials machining |

Bio-inspired Nano-Coatings | Adaptive cutting environments | Self-adaptive, progressive wear resistance | Advanced and emerging machining applications |

Hiboo Tools leads the industry by offering colorful single-edge aluminum milling cutters with advanced coatings. These tools deliver high-quality surface finishes, reduce friction, and enable efficient chip removal. Their commitment to innovation ensures that customers receive reliable solutions for every aluminum end mill application.

Tool Geometries

Specialized tool geometries have transformed the performance of the aluminum end mill. Engineers now design tools with advanced flute shapes and helix angles to achieve higher feed rates and better machining results. These innovations allow machinists to remove more material in less time while maintaining accuracy and tool life.

Variable Helix Designs

Vibration Reduction

Variable helix designs play a critical role in reducing vibration during milling. By altering the helix angle along the cutting edge, these tools disrupt the regular patterns that cause harmonic chatter. This approach leads to smoother operation and less noise in the machining process.

Industry testing reports up to 80% reduction in harmonic chatter in certain applications with variable helix and variable pitch end mills.

Variable helix designs disrupt harmonic resonance patterns, significantly reducing chatter and vibration.

These designs improve stability during high-speed machining and enhance surface finish quality.

The combination of variable helix angles with variable pitch spacing creates a powerful anti-vibration system, especially effective in challenging machining scenarios.

Scientific research confirms that variable helix end mills offer much greater stability and productivity than standard tools. Analytical models and experiments show that these designs suppress chatter and improve machining stability. As a result, machinists achieve better surface finishes and longer tool life.

High-Speed Machining

Variable helix designs also support high-speed machining. The unique geometry allows the tool to cut smoothly at elevated speeds without sacrificing accuracy. This feature proves essential for industries that demand rapid production and tight tolerances. Machinists can push feed rates higher, knowing the tool will resist vibration and maintain a consistent chip load.

Micro-Edge Prep

Surface Finish

Micro-edge preparation involves refining the cutting edge at a microscopic level. This process removes imperfections and creates a uniform edge profile. A smoother edge reduces friction and heat during cutting, which leads to improved surface finishes on the workpiece. In practice, a four-flute end mill with a 30-degree helix angle has shown optimized tool life and surface finish when machining tough materials.

Precision

Precision increases with micro-edge prep. The uniform edge profile ensures each cut remains consistent, even at high speeds. Specialized flute designs and edge treatments improve chip evacuation, which reduces heat and tool wear. High-feed end mills with small entering angles and large axial depths of cut allow increased feed rates and improved material removal rates while minimizing tool wear and heat generation. These features enable machinists to achieve tight tolerances and repeatable results, even in complex 3D milling operations.

Tip: When selecting an aluminum end mill, consider tools with variable helix designs and micro-edge prep. These features deliver higher productivity, better surface quality, and longer tool life.

Smart Aluminum End Mill Integration

Image Source: pexels

Embedded Sensors

Real-Time Monitoring

Manufacturers now embed advanced sensors directly into aluminum end mills. These sensors include fiber optic, piezoelectric, micro-photonic, and magneto-strictive types. They monitor critical parameters such as stress, strain, vibration, temperature, and even crack growth during machining. Micro-photonic sensors, for example, offer high spatial and temporal resolution and resist electromagnetic interference, making them ideal for harsh factory environments. Hybrid manufacturing processes, like ultrasonic additive manufacturing, allow engineers to place sensors inside the tool structure. This integration enables real-time monitoring of tool health and performance.

Embedded sensors track cutting forces and vibrations as they happen.

Operators receive instant alerts about tool wear or abnormal conditions.

Real-time data helps prevent tool failure and reduces downtime.

Monitoring systems can trigger maintenance actions before problems escalate.

Data Collection

Sensor integration in machining operations provides a steady stream of valuable data. This data includes information on tool wear, surface integrity, and machining errors. Intelligent signal processing turns raw sensor data into actionable insights. Early detection of tool wear or process errors reduces the need for post-process inspection and rework. As a result, manufacturers achieve higher part quality and more consistent results.

Data collected from embedded sensors supports process optimization.

Operators use this information to adjust machining parameters for better outcomes.

Predictive maintenance becomes possible, extending tool life and reducing costs.

Embedded sensors improve the prognosis of tool life and enable smarter decision-making.

Note: Hiboo tools integrates sensor-ready solutions into its aluminum end mill lineup, supporting real-time monitoring and data-driven process control for smart manufacturing environments.

Industry 4.0

Automation

Industry 4.0 technologies have transformed the way manufacturers use aluminum end mills. Automated CNC machines now work alongside smart sensors and AI-powered software. These systems optimize tool paths, reduce tool wear, and extend cutter lifespan. Automation streamlines production, minimizes human error, and ensures consistent machining quality. Operators benefit from real-time expert assistance and remote training through augmented reality tools, which further improve machine precision and operator effectiveness.

AI-driven software customizes cutting tool designs for specific applications.

Automated CNC machines use real-time data analytics to adjust machining parameters.

Predictive maintenance algorithms reduce unplanned downtime and improve productivity.

Robotics and IoT devices enable adaptive control and process optimization.

CNC Connectivity

Modern CNC machines connect seamlessly with digital tool management systems. These systems use RFID tags and sensors to monitor tool wear, performance, and usage patterns. Real-time monitoring supports predictive maintenance and optimized tooling strategies. Tool presetters, for example, drastically reduce tool setting time and improve measurement precision. Centralized tool presetters serve multiple machines, saving time and cost.

Metric | Manual Method | In-Machine Laser Probe | Advanced Tool Presetter |

Tool Setting Time (seconds) | ~300 | ~150 | 16-32 |

Measurement Repeatability (μm) | N/A | N/A | Better than 2.5 |

Tool Setting Precision (μm) | N/A | N/A | As precise as 1 |

Tool presetters generate 3D CAD models for CAM programs, enhancing workflow integration.

Precision measurements within 1 micron improve surface finish and tool life.

Real-time data sharing through digitized CNC interfaces enhances process learning and maintenance.

Hiboo tools offers digital solutions compatible with Industry 4.0, including sensor-ready end mills and smart tool management systems. Their products support seamless integration with modern CNC equipment, ensuring manufacturers stay ahead in the era of smart manufacturing.

Sustainable Practices

Eco-Friendly Materials

Green Manufacturing

Sustainability stands at the forefront of aluminum end mill technology in 2025. Manufacturers now focus on green manufacturing to reduce environmental impact and conserve resources. They use recycled metals, including aluminum, to limit mining activities and preserve natural resources. Aluminum’s recyclability allows it to be melted and reprocessed, which lowers the demand for new raw materials. Advanced plastic deformation methods enable recycling without energy-intensive melting. This process preserves the material’s properties and reduces the carbon footprint. Solid-state recycling techniques reuse aluminum from complex or heavily processed scrap, supporting a circular economy.

Companies like hiboo tools invest in energy-efficient machinery and renewable energy sources. Their facilities use high-efficiency motors that cut energy consumption by up to 30%. These efforts help lower emissions and promote responsible manufacturing.

Manufacturers also adopt biodegradable cutting fluids. These fluids reduce harmful emissions and protect operators from toxic chemicals. Waste reduction techniques, such as optimized tool paths and recycling of chips and coolant, further minimize material waste. A case study from Cascade Engineering shows a 30% energy savings and a reduced carbon footprint after integrating material recycling and wind energy. Denton Engineering lowered electricity costs by 25% using solar energy in CNC machining. These examples prove that green manufacturing delivers both environmental and economic benefits.

Cost Reduction

Eco-friendly materials and processes do more than protect the environment. They also drive cost savings for manufacturers. Recycled aluminum costs less than virgin material. Energy-efficient equipment reduces utility bills. Waste reduction strategies cut disposal costs and improve overall efficiency. Companies that invest in green manufacturing often see a quick return on investment.

Sustainability Practice | Environmental Benefit | Cost Benefit |

Recycled Aluminum Use | Reduces mining, saves energy | Lowers material costs |

Energy-Efficient Machinery | Cuts emissions | Reduces electricity bills |

Biodegradable Cutting Fluids | Lowers toxic waste | Improves workplace safety |

Waste Reduction Techniques | Minimizes landfill use | Cuts disposal expenses |

Tool Life Extension

Reduced Waste

Extending tool life remains a key strategy for sustainable machining. Longer-lasting tools generate less waste because operators replace them less often. Advanced coatings and optimized geometries help end mills resist wear and maintain performance over time. Fewer tool changes mean less scrap and lower consumption of raw materials. Manufacturers also recycle worn tools, further reducing landfill waste.

Economic Impact

Longer tool life leads to significant economic advantages. Companies spend less on replacement tools and reduce downtime for tool changes. Improved tool performance ensures consistent product quality, which minimizes rework and scrap. These factors combine to lower production costs and boost profitability.

Hiboo tools supports sustainability by offering end mills with advanced coatings and durable materials. Their products help customers achieve longer tool life, reduce waste, and operate more efficiently. By prioritizing green manufacturing and tool longevity, hiboo tools sets a strong example for the industry in 2025.

Application Customization

Industry Solutions

Aerospace

Aerospace manufacturers demand high-precision parts that can withstand extreme conditions. They use custom aluminum end mill solutions to produce lightweight components with tight tolerances. These parts must resist corrosion and maintain strength during flight. Companies often select alloys like 6061 for their balance of strength and machinability. Custom end mills with specific flute counts and advanced coatings help achieve the required surface finish and durability. Rigorous quality control ensures each part meets strict aerospace standards.

Automotive

Automotive companies rely on tailored aluminum end mill tools to create engine parts, brackets, and housings. These parts need to be strong, accurate, and lightweight. Customization allows manufacturers to choose the right tool geometry and coating for each operation, such as roughing or finishing. For example, 2-flute carbide end mills work well for roughing, while 3-flute designs provide a smoother finish. Anodized aluminum parts offer improved corrosion resistance, which is essential for vehicles exposed to harsh environments. CNC machining with custom tools supports scalable production and consistent quality.

Electronics

Electronics manufacturers use custom aluminum end mill solutions to produce housings, heat sinks, and connectors. These parts require excellent thermal management and a high-quality appearance. Custom tooling enables the creation of complex shapes and fine details. Anodized finishes enhance both the look and durability of electronic components. Manufacturers select specific flute counts and coatings to optimize chip evacuation and surface finish, ensuring reliable performance in compact devices.

Customization in aluminum end mill design addresses the unique needs of each industry. Manufacturers benefit from improved efficiency, better product quality, and reduced production costs.

Industry | Weight Reduction (%) | Corrosion Resistance (1-10) | Aesthetic Appeal (1-10) | Tool Life Impact (%) | Thermal Management Efficiency (%) | Sustainability (1-10) |

Aerospace | 25-35 | 9 | 8 | -30 | 85 | 9 |

Automotive | 20-30 | 8 | 9 | -25 | 80 | 8 |

Electronics | 15-25 | 7 | 10 | -20 | 90 | 7 |

Rapid Prototyping

On-Demand Production

Rapid prototyping has changed how manufacturers approach aluminum machining. Companies now produce prototypes in days instead of weeks. This speed allows for quick design changes and faster product launches. Additive manufacturing, such as 3D printing, creates complex tool shapes that traditional methods cannot achieve. Manufacturers reduce material waste and shorten production cycles, making on-demand production more cost-effective.

Rapid tooling cuts lead times, enabling faster prototype delivery.

Additive manufacturing supports complex geometries and design changes.

Shorter cycles reduce labor and rework costs.

Design Flexibility

Design flexibility is a major advantage of rapid prototyping. Engineers can test multiple designs quickly and refine them based on feedback. Each iteration improves the final product and reduces the risk of costly errors. In industries like automotive and medical devices, rapid prototyping leads to better product quality and faster time-to-market. The ability to move from CAD models to physical parts in a short time supports innovation and competitiveness.

Hiboo tools offers custom aluminum end mill solutions for aerospace, automotive, and electronics applications. Their rapid prototyping services help customers test and refine designs quickly. Case studies show that hiboo tools’ tailored solutions deliver improved part quality, reduced lead times, and greater production efficiency.

Software and Simulation

Advanced Modeling

Design Accuracy

Advanced modeling software has changed how engineers design aluminum end mills. Designers now use three-dimensional solid models to visualize every detail of a tool before production. This digital approach allows them to adjust features like rake angle and inner radius with precision. They can simulate the grinding process by combining the shapes of the grinding wheel and the tool blank. This method removes the need for physical prototypes, saving both time and resources.

Finite element analysis tools, such as AdvantEdge, let engineers simulate cutting forces, temperatures, and chip formation. These simulations use mathematical models based on plastic deformation and fracture mechanics. By analyzing these factors, designers can predict how an end mill will perform in real-world conditions. This process helps them optimize tool geometry and select the best machining parameters. As a result, manufacturers produce end mills that last longer and deliver better results in aluminum machining.

Machining Simulation

Machining simulation provides a virtual testing ground for new tool designs. Engineers can see how a tool interacts with aluminum under different speeds and feeds. The software predicts wear patterns, heat buildup, and chip flow. This information guides improvements in tool shape and material selection. By using simulation, companies avoid costly trial-and-error experiments on the shop floor.

Simulation data gives manufacturers confidence in their designs. They can launch new products faster and with fewer risks.

Turnkey Solutions

Productivity

Turnkey simulation solutions offer ready-to-use packages for machining operations. These systems combine advanced software, hardware, and process know-how. Companies that adopt turnkey solutions see rapid gains in productivity. For example, some operations report at least a 30% increase in output within two months. Quality parts come off the line from day one, which speeds up the return on investment.

Improvement Aspect | Reported Result |

Productivity Increase | At least 30% increase within 2 months |

Cycle Time Reduction | Order-to-shipment time reduced from weeks to days |

ROI | Quality parts produced from day one, faster capital return |

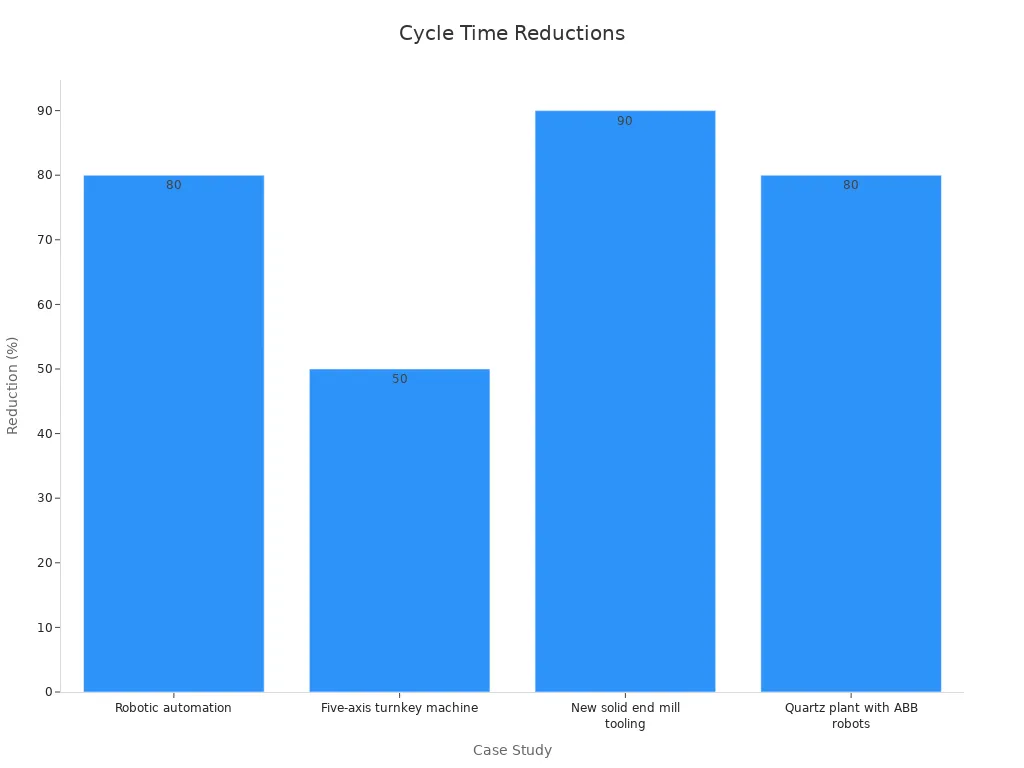

Cycle Time Reduction

Cycle time reduction stands as a key benefit of turnkey solutions. Robotic automation can cut production time from 25 minutes to just 5 minutes, resulting in a fourfold increase in output. Five-axis turnkey machines combine multiple operations, reducing cycle times by up to 50%. New solid end mill tooling has achieved up to 90% cycle time reduction in some cases. In one quartz plant, ABB robots helped cut cycle time by 80%.

Companies that use turnkey simulation solutions deliver parts faster, improve efficiency, and stay competitive in the fast-changing world of aluminum machining.

Emerging trends in end mill technology drive machining forward in 2025. Companies see longer tool life, smoother finishes, and higher precision.

Modern coatings and materials reduce heat and wear, allowing tools to last longer and perform better.

Users report faster cycle times, fewer tool changes, and improved consistency.

Industries like aerospace and automotive achieve better results and lower costs.

Hiboo tools provides the latest solutions for those seeking to upgrade their machining operations. Teams can apply these innovations to boost productivity and stay competitive.

FAQ

What makes nano-coatings important for aluminum end mills?

Nano-coatings increase heat resistance and tool life. They help tools stay sharp and last longer during high-speed machining. Many manufacturers choose nano-coatings for better performance and lower costs.

How do embedded sensors improve machining with aluminum end mills?

Embedded sensors track tool wear, vibration, and temperature in real time. Operators use this data to prevent tool failure and reduce downtime. Smart monitoring leads to higher quality and safer operations.

Why do manufacturers prefer variable helix designs?

Variable helix designs reduce vibration and chatter. These tools cut more smoothly and produce better surface finishes. Machinists achieve higher speeds and improved accuracy with variable helix end mills.

Are eco-friendly materials cost-effective for manufacturers?

Yes. Eco-friendly materials, such as recycled aluminum, lower material costs and reduce waste. Companies also save money by using energy-efficient machines and biodegradable cutting fluids.

How does rapid prototyping benefit aluminum machining?

Rapid prototyping allows fast production of test parts. Engineers can make quick design changes and see results in days. This process speeds up product development and reduces errors.

Can software simulation replace physical tool testing?

Software simulation predicts tool performance and wear. Engineers use these tools to test designs before making physical prototypes. This approach saves time and resources.

What industries benefit most from custom aluminum end mills?

Aerospace, automotive, and electronics industries gain the most. Custom end mills help these sectors meet strict quality standards and produce complex parts efficiently.

Where can professionals find the latest aluminum end mill solutions?

Professionals visit hiboo tools for advanced aluminum end mill technologies. The company offers innovative coatings, smart integration, and custom solutions for many industries.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg