Products Function

HRC50 3flutes mirco end mills

| | tungsten carbide 3 flutes micro end mill milling machine |

| | |

| Helix Angle | 45° |

| Flutes | 3 Flutes |

| Coating | TiSiAlN/nACo blue/uncoated |

| | |

| | |

| | CNC Milling Machine, engraving machine, precision engraving machine |

| Workpiece material | Steel, Cast iron, Alloy steel, Copper, Aluminium etc |

| | |

| Style | Mirco end mill |

Features:

Sharp cutting edge for burr-free finishing

High-speed compatible

Low friction, anti-stick surface

Excellent tool balance for stable micro machining

Suitable for processing steel, stainless steel, nickel alloy, Titanium alloy, cast iron, plastic and other materials' hardness below HRC55

"3-blade aluminum small diameter cutter" is a small diameter milling cutter designed specifically for aluminum and other non-ferrous metals (such as copper, brass, etc.), usually used for high-speed cutting. The following are its main features:

3-blade structure: The three-blade design increases the number of cutting edges per revolution, improves the material removal rate in the processing of softer metals such as aluminum, and maintains a high surface finish. The three-blade design also ensures smooth chip removal and is suitable for high-speed processing.

Small diameter design: The small diameter is suitable for milling small, precise parts and complex structures. The processing process is flexible and fine, especially suitable for precision molds, aerospace parts and 3C products. Details processing.

Helix angle and cutting edge designed specifically for aluminum: In view of the softness of aluminum, it is usually designed with a high helix angle (such as 45°-55°). This structure can provide smoother cutting results. The cutting edge is usually sharp and easy to cut, which helps to reduce cutting heat and prevent aluminum from sticking.

Deep groove chip removal groove: The wide chip removal groove can quickly remove a large amount of chips, reduce the risk of clogging, and improve processing efficiency.

Smooth coating or no coating: Aluminum tools are usually uncoated or use special smooth coatings (such as DLC coatings) to prevent aluminum from adhering to the tool at high temperatures and improve wear resistance.

This type of tool is suitable for fine processing of aluminum alloys and other soft metals, such as contour milling of electronic product housings, mold aluminum alloy parts, shallow groove processing, etc.

The following Specification for your refer, We also provide the OEM or ODM service.

| (Order No) | Cutting | Flute | Shank | A.0.L |

| d | l | D | L |

| 1.0×3×4D×50L×3F | 1 | 3 |

4 |

50 |

| 1.5×4×4D×50L×3F | 1.5 | 4 |

| 2.0×6×4D×50L×3F | 2 | 6 |

| 2.5×8×4D×50L×3F | 2.5 | 8 |

| 3.0×8×4D×50L×3F | 3 | 8 |

| 3.5×10×4D×50L×3F | 3.5 | 10 |

| 4.0×11×4D×50L×3F | 4 | 11 |

| 3.0× 8×6D×50L×3F | 3 | 8 |

6 |

| 3.5×10×6D×50L×3F | 3.5 | 10 |

| 4.0×11×6D×50L×3F | 4 | 11 |

| 4.5×13×6D×50L×3F | 4.5 | 13 |

| 5.0×13×6D×50L×3F | 5 | 13 |

| 5.5×13×6D×50L×3F | 5.5 | 13 |

| 6.0×15×6D×50L×3F | 6 | 15 |

| 7.0×16×8D×60L×3F | 7 | 16 | 8 | 60 |

| 8.0 ×20×8D×60L×3F | 8 | 20 |

| 9 ×20×10D×75L×3F | 9 | 20 | 10 | 75 |

| 10×25×10D×75L×3F | 10 | 25 |

| 11×25×12D×75L×3F | 11 | 25 | 12 |

| 12×30×12D×75L×3F | 12 | 30 |

| 14×35×14D×100L×3F | 14 | 35 | 14 | 100 |

| 16×40×16D×100L×3F | 16 | 40 | 16 |

| 18×40×18D×100L×3F | 18 | 40 | 18 |

| 20×45×20D×100L×3F | 20 | 45 | 20 |

Clients Good Feedback

"We've been using Hiboo Tool’s solid carbide square end mills for over a year, and they’ve greatly improved our machining efficiency and tool life. Highly recommend for any precision milling job."

- Alex, Russia

Factory

"Hiboo Tool is a leading square end mill manufacturer based in China. Our solid carbide square end mills are known for their high precision and durability, ideal for a wide range of applications including CNC machining, aerospace, automotive, and medical industries. Whether you need standard or custom-made solutions, we provide high-quality cutting tools at competitive prices."

We specialized in producing and exporting Carbide End Mills, Drills, Inserts, Reamers and more other customized cutting tools.

Well trained production team, all ends mills are produced ANCA Grinding Machine.

Made by world latest 5-AXIS tools grinding machine, promise the quality and precision of cutter.

Why Choose Hiboo Tool's Square End Mills?

Precision Manufacturing: We use advanced CNC grinding technology to produce high-precision solid carbide square end mills that deliver consistent performance.

Durability and Wear Resistance: Our solid carbide end mills feature exceptional hardness (up to HRC 65) and resistance to wear, making them ideal for high-speed machining and extended tool life.

Wide Range of Sizes and Customization: We offer a wide range of standard sizes and can also create custom-made square end mills to suit your specific machining needs.

Competitive Pricing: As a leading square end mill manufacturer in China, we offer high-quality products at competitive prices with quick turnaround times.

Global Shipping: We ship worldwide, offering fast and reliable delivery to international customers, especially to markets in Russia, Mexico, Brazil, Italy, Malaysia, India, and South Africa.

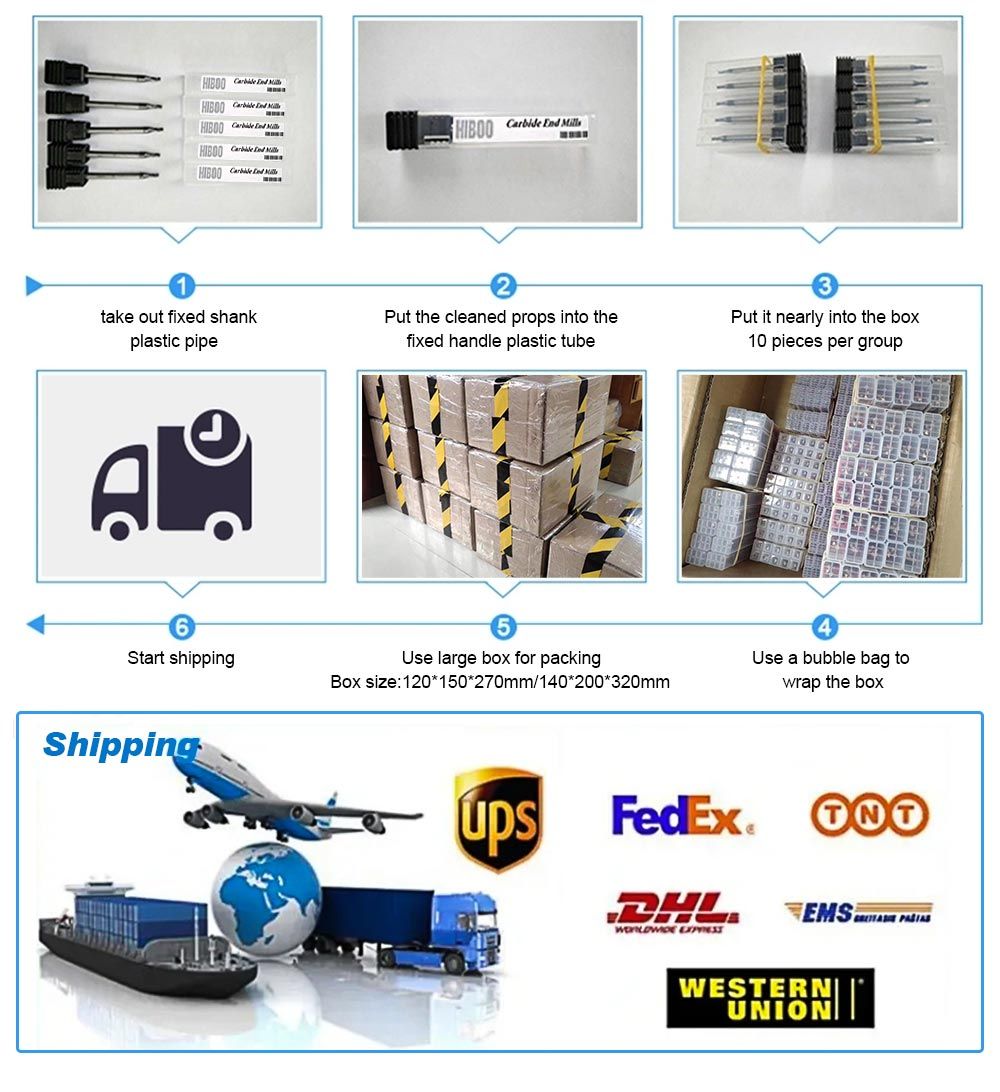

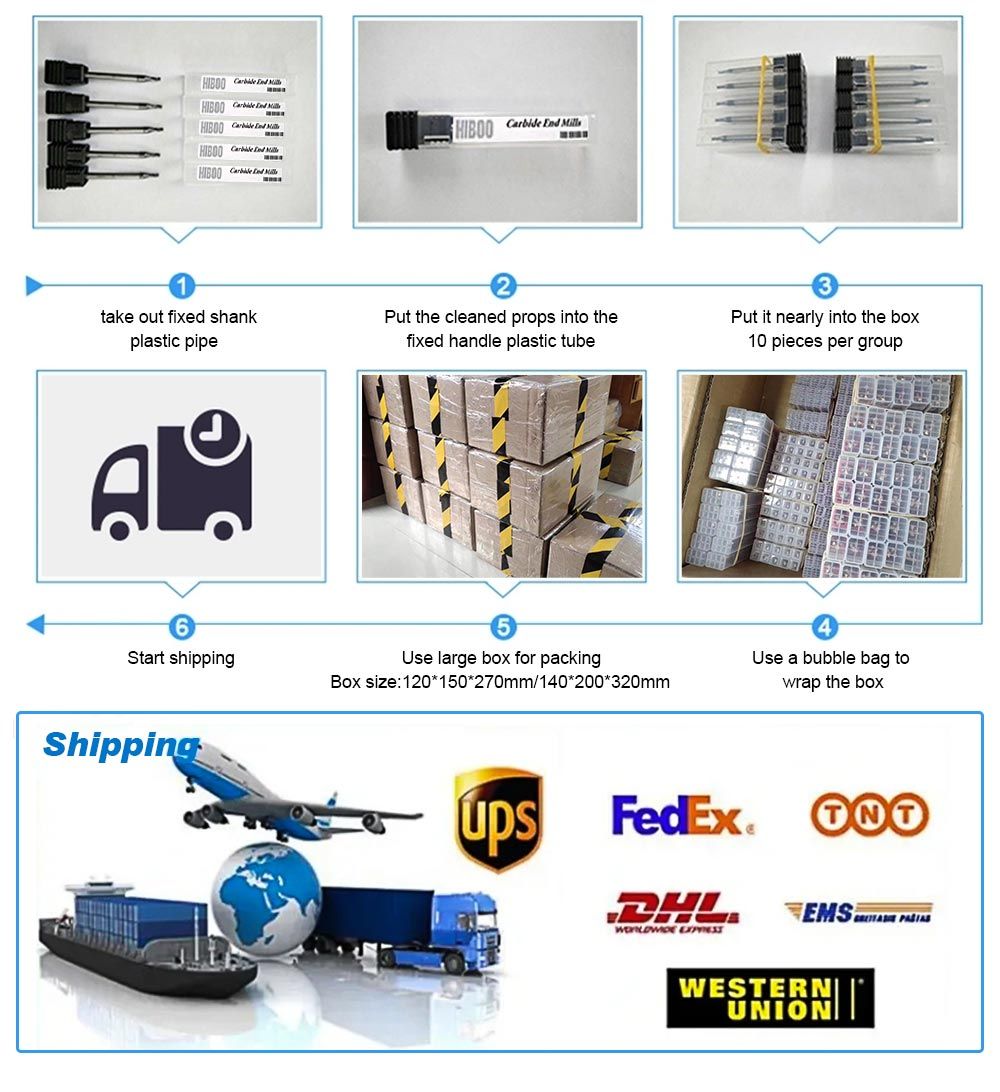

Packaging & Shipping

Package and shipping details

Laser brand on the cutter's shank , 1 pc in a plastic tube , 10pcs a group

We cooperated with DHL , Fedex, UPS ,TNT, EMS and other express you wanted.

Delivery Time

For samples , we dispatch your tools in 2-7 workdays .

For formal orders,We delivery tools to you in 7-30 workdays , it will depond on your order quantity.

Payment Term

T/T ,Western Union , MoneyGram,L/C

Our Exhibition

Over the years, we have participated in multiple leading trade shows across the globe, including those in Russia, Mexico, Brazil, Italy, Malaysia, India, and South Africa. These international exhibitions have allowed us to showcase our products, connect with global distributors, and stay ahead of industry trends. By engaging with professionals worldwide, we continue to improve our offerings and meet the unique needs of customers in various industries."

FAQ

1. Are you manufacturer? Do you have factory?

We are professional manufacturer,have more than20 years experience in this field.

2.what can you buy from us?

We specialized in producing and exporting Carbide End Mills, Drills, Inserts, cutter bodies,Reamers and more other customized cutting tools.

3. Is free shipping possible?

We don't offer free shipping service,but we will give you some discount if you buy large quantity products. We have cooperation Express Companies,can offer you the best price of shipping cost.

4. Can you send products to our Forwarder in China?

Yes,if you have Forwarder in China,we will glad to send products to him/her.

5.What cnc machines do you use?

More than 5 pcs ANCA ,Walter CNC grind machines ,and professional staff to make sure the good quality , with short delivery time .

6.Can we be your distributor?

Yes, of course . Welcome to contact us for this matter.

7.Can you product special cutting tools according to drwaing?

Yes We can. We will check the drwaing and reply you in 1 workday.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg