Hiboo Tools presents a premium Ball Nose End Mill series engineered for demanding machining applications. This HRC58-rated Ball Nose End Mill features an optimized 2-flute design and extended neck geometry, delivering exceptional performance in deep cavity work and complex 3D contouring. Manufactured from micro-grain solid carbide, this Long Neck Ball Nose End Mill maintains stability and precision when processing hard materials up to 58 HRC.

Characteristics of Ball Nose End Mills:

Extended Reach Design: The specialized long neck ball nose end mill provides superior access to deep pockets and complex geometries, making this extended ball nose end mill ideal for deep cavity machining.

Efficient Chip Evacuation: Two-flute configuration in our ball nose end mill ensures smooth chip removal during continuous machining operations, allowing this premium ball nose end mill to maintain consistent performance.

Enhanced Rigidity: Solid carbide construction minimizes vibration and deflection in extended-reach applications, giving this robust ball nose end mill exceptional stability during deep cutting operations.

Multiple Coating Options: Available with TiAlN, AlTiN, or TiSiN coatings for improved wear resistance and thermal protection, each ball nose end mill can be customized to match specific machining requirements.

Material | Carbide |

Coating | TiSiAIN / nACo blue / Uncoated |

Customized Support | OEM, ODM |

Product Name | 2 Flute Mirco End Mill |

Flute | 2 Flutes |

Helix Angel | 35° |

Application | General steel, Castiron, Mould steel and Titanium alloy etc |

Controlling Mode | CNC Tooling System |

Machine Type | CNC Miling Machine |

MOQ | 1pcs/box |

Shipment | UPS, Fedex, DHL, EMS or Sea |

Dellvery Time | 6-14 days |

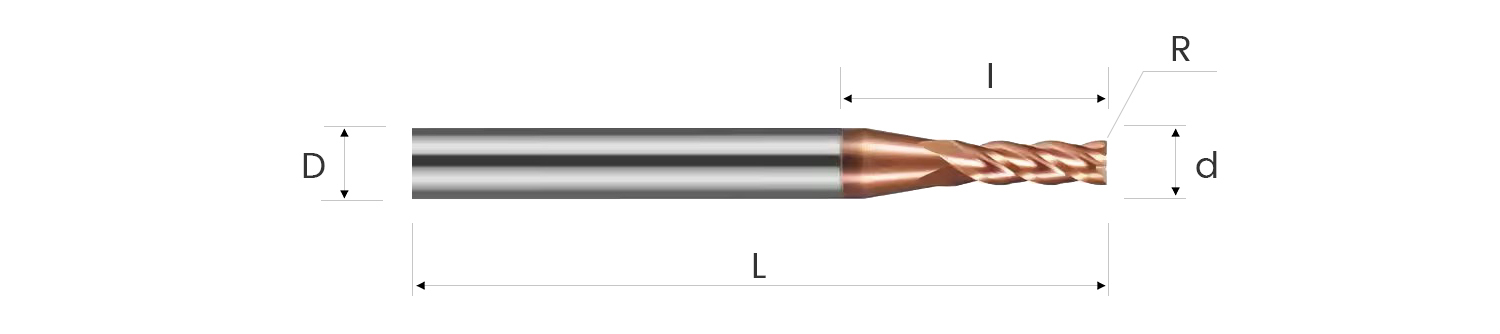

long neck ball nose end mill |

(d Dia.) | (I Length of Cut) | (D Shank Dia.) | O.A.L |

0.1 | 0.2 | 4D | 50L |

0.15 | 0.3 | 4D | 50L |

0.2 | 0.4 | 4D | 50L |

0.3 | 0.6 | 4D | 50L |

0.4 | 0.8 | 4D | 50L |

0.5 | 1 | 4D | 50L |

0.6 | 1.2 | 4D | 50L |

0.7 | 1.4 | 4D | 50L |

0.8 | 1.6 | 4D | 50L |

0.9 | 1.8 | 4D | 50L |

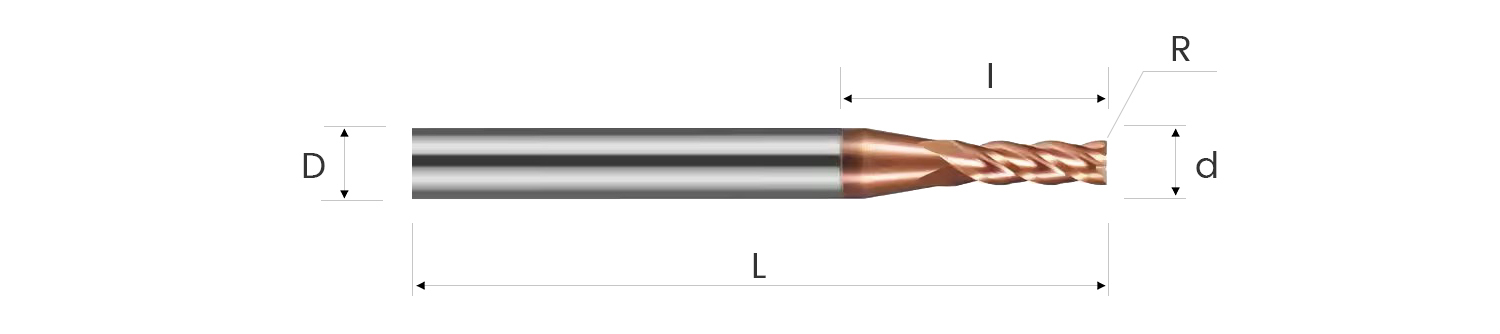

(R Dia.) | (I Length of Cut) | (D Shank Dia.) | O.A.L |

R0.1 | 0.4 | 4D | 50L |

R0.15 | 0.6 | 4D | 50L |

R0.2 | 0.8 | 4D | 50L |

R0.25 | 1 | 4D | 50L |

R0.3 | 1.2 | 4D | 50L |

R0.35 | 1.4 | 4D | 50L |

R0.4 | 1.6 | 4D | 50L |

R0.45 | 1.8 | 4D | 50L |

Why Choose Our Ball Nose End Mill?

Precision in Complex Machining

Our Ball Nose End Mill is used for 3D profiling and maintaining high detail on the part. This Long Neck Ball Nose End Mill offers dimensional accuracy even in long-reach, deep-cavity applications.

Optimized for Hard Materials

Designed for aggressive milling of most materials, this Ball Nose End Mill yields unrivaled performance on hardened steels, tool steels, and additive steels. Premium micro-grain carbide and advanced coating technology combine to provide very long tool life in high-temperature machining environments.

Enhanced Productivity

The optimized structure of 2 Flute Ball Nose End Mill provides excellent chip evacuation, minimizing the risk of ambiguity and tool breakage. Extended neck design for deeper cutting depths and provides greater clearance with a critical profile radius, which ensures efficient machining of complex parts.

Applications

• 3D surface machining and profiling

• Mold and die manufacturing

• Aerospace component processing

• Automotive mold production

• Medical device manufacturing

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg