Brand

| Hiboo |

| | Small aperture boring tool |

| | HRC42-60 degrees |

| Material | Tungsten steel |

| MOQ | 10pcs |

| Coating | nano coating |

| Shank diameter | 3mm to 8 mm, or inch size |

| Shank Type | Weldon, or round shank |

| Machining type | Internal Step, profile, thread, groove |

| Face groove turning | Available |

| Cutting length | 0.2-80mm |

| Product features | Almost all cutting edge geometry can be specified |

| Connection diameter(DCON) | 4 mm |

| Overall length | 40-75 mm |

| Weight of item(WT) | 0.015 kg |

| Diameter | 0.15-12 |

| Cutting Diameter | φ1-φ8 |

| Workpiece material | For Steel, Stainless Steel, Cast iron, Aluminum alloys, also for Titanium alloys |

| | High Speed Machining/Coolant |

| | Stainless steel, die steel, ball milling cast iron, alloy steel, modulation steel |

| Product performance | Sharp wear-resistant, hard and soft high finish, surface polishing |

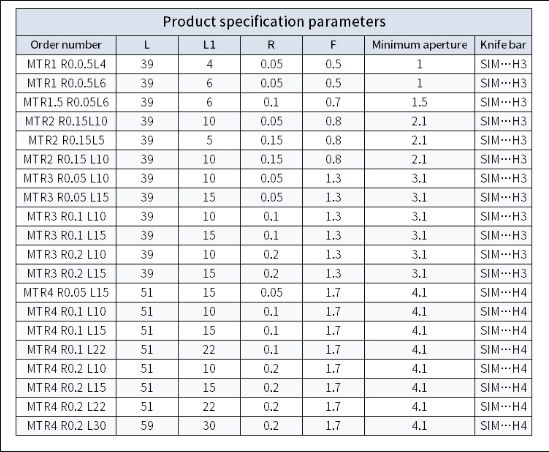

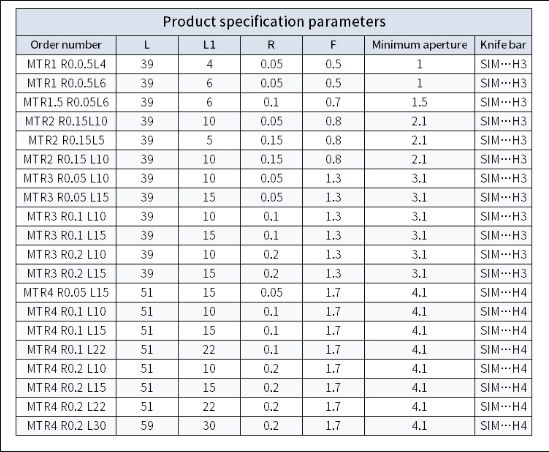

Product Specification:

The T40 boring tool is a high-efficiency boring tool, usually used for precision machining. Its main features include:

Tool type: suitable for fine boring and rough boring, especially in the machining of cast iron, steel and alloy materials.

Tool material: generally uses high-performance cemented carbide, with high wear resistance and strength.

Diameter: T40 is usually used for smaller diameter hole machining, suitable for occasions with high precision requirements.

Application field: widely used in automobile, aviation, mold and other industries.

Detailed specifications

Tool diameter: usually 40mm, but can be selected according to processing requirements.

Tool material: usually made of high-quality carbide or other high-performance materials, with good wear resistance and heat resistance.

Cutting angle: design optimization to improve cutting efficiency and reduce vibration.

Blade type: replaceable blade design, easy maintenance and replacement, and improve tool life.

Cooling method: generally equipped with cooling holes to provide sufficient cooling during processing to prevent overheating.

Application examples

Automotive industry: precision boring on engine cylinder blocks or crankshafts to ensure the roundness and surface finish of holes.

Aerospace: used for processing aircraft fuselage parts, requiring high-strength and high-precision hole processing.

Mold manufacturing: boring on the cooling holes or guide holes of the mold to ensure mold performance and service life.

Heavy machinery: boring the bearing seats and other key components of heavy equipment to improve the fit accuracy.

Changzhou Hiboo Tools Co., Ltd is a high-tech enterprise with all vitality, potential and comprehensive Strength. The company located in Changzhou, Jiangsu, China, a unique place near by Shanghai.We are Gold Supplier who specialized in producting and exporting Carbide End Mills, Drills, Inserts, Reamers and more other customized cutting tools.The efficient workshop and Imported 5AXIS grind machines run by skillful operators. The strict inspection standards to make sure each cutter is inspected by Zoller Measuring and Inspecting Machine. Now, Our monthly output up to 50000pcs of carbide end mills, drills ect, More than 20000 cutters are in stock which meet your urgent requirements. Enough Raw Materials in stock to keep the price stability.

Changzhou Hiboo Tools Co., Ltd is a high-tech enterprise with all vitality, potential and comprehensive Strength. The company located in Changzhou, Jiangsu, China, a unique place near by Shanghai.We are Gold Supplier who specialized in producting and exporting Carbide End Mills, Drills, Inserts, Reamers and more other customized cutting tools.The efficient workshop and Imported 5AXIS grind machines run by skillful operators. The strict inspection standards to make sure each cutter is inspected by Zoller Measuring and Inspecting Machine. Now, Our monthly output up to 50000pcs of carbide end mills, drills ect, More than 20000 cutters are in stock which meet your urgent requirements. Enough Raw Materials in stock to keep the price stability.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg

Changzhou Hiboo Tools Co., Ltd is a high-tech enterprise with all vitality, potential and comprehensive Strength. The company located in Changzhou, Jiangsu, China, a unique place near by Shanghai.We are Gold Supplier who specialized in producting and exporting Carbide End Mills, Drills, Inserts, Reamers and more other customized cutting tools.The efficient workshop and Imported 5AXIS grind machines run by skillful operators. The strict inspection standards to make sure each cutter is inspected by Zoller Measuring and Inspecting Machine. Now, Our monthly output up to 50000pcs of carbide end mills, drills ect, More than 20000 cutters are in stock which meet your urgent requirements. Enough Raw Materials in stock to keep the price stability.

Changzhou Hiboo Tools Co., Ltd is a high-tech enterprise with all vitality, potential and comprehensive Strength. The company located in Changzhou, Jiangsu, China, a unique place near by Shanghai.We are Gold Supplier who specialized in producting and exporting Carbide End Mills, Drills, Inserts, Reamers and more other customized cutting tools.The efficient workshop and Imported 5AXIS grind machines run by skillful operators. The strict inspection standards to make sure each cutter is inspected by Zoller Measuring and Inspecting Machine. Now, Our monthly output up to 50000pcs of carbide end mills, drills ect, More than 20000 cutters are in stock which meet your urgent requirements. Enough Raw Materials in stock to keep the price stability.