You want great results for your machining projects. Pick from these top 10 custom end mill manufacturers for 2025: Hiboo Tool, Shenzhen Zhuoluoyu Precision Tool Co., Ltd., DATRON Dynamics, Inc., Melin Tool, Utensileria Carmon Srl, Sandvik Coromant, Kennametal, ISCAR, EndMillMan.com LLC, and Union Tool. These end mill manufacturers are known for new ideas, custom solutions, and high-quality cutting tools. The global market for custom end mills may reach USD 57.3 billion by 2025. This is because more people want Carbide Square End Mills, square end mill, and flat end mill choices. You need a cutting tool manufacturer that fits your needs.

Key Takeaways

Pick top makers like Hiboo Tool and Sandvik Coromant for good custom end mills made for your needs. The world market for custom end mills may reach USD 57.3 billion by 2025. This shows more people want special cutting tools. Find makers that let you choose options so you get the right tools for your jobs and materials. Choose companies with strong quality checks, like ISO certifications, to make sure you get good and safe cutting tools. Think about how long it takes to get your order and if the company helps customers, so you get your tools on time and get help when you need it.

Top Custom End Mill Manufacturers

When you want the best custom end mill cutters, you need to know which brands are the best. These top cutting tool manufacturers are leading in 2025. Each company has something special. Some make high-performance carbide end mills. Others offer custom solutions for machining. Let’s see why these end mill brands are great for your needs.

2025 Market Share at a Glance:

Hiboo Tool (China)

You want your custom end mill cutter to be precise and reliable. Hiboo Tool gives you both. This company makes high-performance carbide end mills and custom end mill cutters for many jobs. Their tools use strong carbide and special coatings like AlTiN and TiAlN. These coatings help the tools last longer and cut faster. Hiboo Tool lets you order custom cutting tools for your needs. Their products include carbide square end mills, ball end mills, and corner radius end mills. You can use these cutters for aluminum, steel, stainless steel, titanium alloy, wood, or acrylic. Hiboo Tool uses 5-axis grinding machines and checks quality carefully. Every end mill cutter meets high standards. If you want fast and strong milling, Hiboo Tool is a top global manufacturer.

Key Features:

High-performance coatings make tools last longer

Custom options for special machining jobs

Carbide material is hard and resists wear

Multi-point taper drills work for many uses

1-month warranty gives you peace of mind

Shenzhen Zhuoluoyu Precision Tool Co., Ltd. (China)

If you work in electronics, cars, or planes, Shenzhen Zhuoluoyu Precision Tool Co., Ltd. has custom end mill cutters for you. This company has a 14.2% click share in the cutting tools market. They are a leader among top cutting tool manufacturers. You get carbide end mills and custom end mill cutters that meet strict rules. They focus on CNC machining, optics, and healthcare. You can trust their end mill brands for very precise work. Shenzhen Zhuoluoyu’s custom end mill cutters help you get smooth finishes and tight fits, even for hard jobs.

| Industries Served |

| Consumer Electronics |

| Automotive |

| Aerospace |

| Healthcare |

| Optics |

| CNC Machining |

DATRON Dynamics, Inc. (USA)

You want new ideas in your custom end mill cutter. DATRON Dynamics, Inc. brings advanced technology to the cutting tools market. Their Neo VMC uses a vacuum workholding system. You can put parts on the table without clamps. This makes setup and machining faster. DATRON also shows interactive machining demos. You can watch how their custom end mill cutters work in real time. They focus on fast milling and easy use. This makes them a favorite for high-speed, high-performance carbide end mills. If you need custom end mill cutters for quick jobs or big runs, DATRON Dynamics helps you do better work.

Faster setup and milling with vacuum workholding

Interactive demos help you learn

Custom end mill cutters for fast machining

Melin Tool (USA)

You want tools you can trust. Melin Tool is known for high-quality carbide end mills and custom end mill cutters. They care about customer happiness and check every end mill cutter for quality. Melin Tool improves their quality checks every day. You can use their custom end mill cutters for many jobs, like aerospace or medical devices. Their focus on quality makes them a trusted end mill brand.

Utensileria Carmon Srl (Italy)

Utensileria Carmon Srl is well-known in Europe for custom end mill cutters. They offer many carbide end mills and custom end mill cutters for fast machining. Their tools work well in cars, planes, and engineering. Utensileria Carmon Srl mixes Italian skill with new technology. You get end mill cutters that are both precise and strong. Their 7.1% market share shows they are important in the cutting tools market.

Sandvik Coromant (Sweden)

You want new ideas and worldwide support. Sandvik Coromant has custom end mill cutters with special coatings and shapes. Their carbide end mills work for fast machining and tough materials. Sandvik Coromant helps industries like aerospace, cars, and energy. You can count on their end mill brands for steady work and long tool life. Their worldwide network means you get help anywhere.

Special coatings for longer tool life

Custom end mill cutters for many industries

Strong support everywhere

Kennametal (USA)

Kennametal gives you custom end mill cutters with special designs. Their open 5-flute design and strong core help remove more material and last longer. Special flute shapes and chip gashes help chips move out and keep things cool. You can use their solid carbide end mills for steel, stainless steel, high-temperature alloys, and cast iron. Kennametal’s custom end mill cutters help you handle tough jobs with confidence.

| Feature Description | Benefit |

| Open 5-flute design with strong core | Removes more material, lasts longer |

| Special W-flute shape | Moves chips out better |

| Centerless end face design | Better for ramping and plunging |

| Eccentric relief | Makes edges stronger |

| Chip gashes | Keeps tools cool |

| Solid carbide end mill | Works on many materials |

ISCAR (Israel)

ISCAR is famous for custom end mill cutters and high-performance carbide end mills. You get tools made for fast machining and tricky shapes. ISCAR helps industries like aerospace, cars, and die/mold. Their custom end mill cutters help you get tight fits and smooth finishes. ISCAR spends a lot on research and development. You always get the newest cutting tool technology.

Focus on research and new ideas

Custom end mill cutters for hard jobs

Fast, high-performance carbide end mills

EndMillMan.com LLC (USA)

If you need custom end mill cutters for special jobs, EndMillMan.com LLC is a good choice. They have over 25,000 items in stock. You can find the right end mill cutter for any job. Their advanced manufacturing and skilled workers make high-quality carbide end mills. EndMillMan.com LLC gives you fast service, usually in 10-14 days. Their great customer service makes them a favorite end mill brand for custom work.

| Evidence | Description |

| High-quality cutting tools | Made for special uses |

| Advanced manufacturing | Makes tools precise and good |

| Skilled workers | High standards for every tool |

| Customer service | Good help for buyers |

| Big inventory | Over 25,000 items ready |

| Fast service | Custom tools in 10-14 days |

Union Tool (Japan)

Union Tool is strong in Asia, Europe, and America. You get custom end mill cutters and carbide end mills trusted by many companies. Union Tool makes carbide end mills, PCB drills, and precision tools. They are known for quality and new ideas. If you want reliable custom end mill cutters for electronics, cars, or general jobs, Union Tool is a good choice.

| Aspect | Details |

| Company Name | Union Tool (佑能工具株式会社) |

| Market Presence | Strong in Asia, Europe, America |

| Specialization | Carbide end mills, PCB drills, precision tools |

| Reputation | Trusted for quality and new ideas |

Tip: When you pick a custom end mill cutter from these brands, you get advanced technology, careful quality checks, and solutions made for your needs. These top global manufacturers help you stay ahead in the cutting tools market.

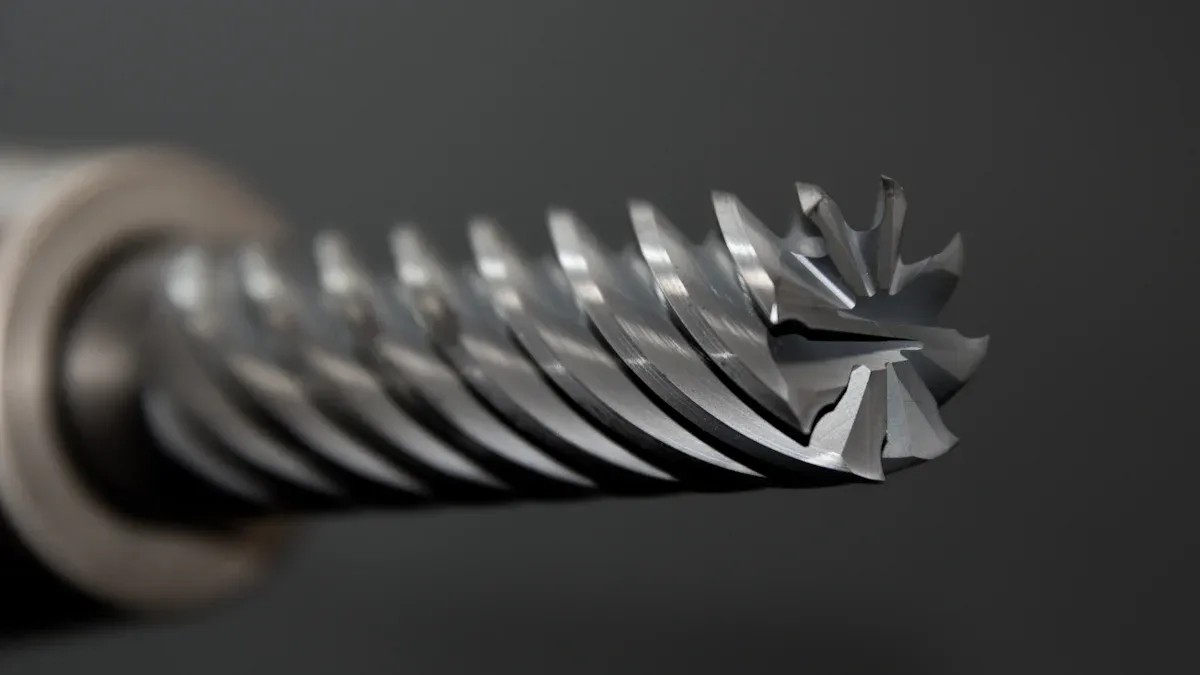

What Makes Custom End Mill Cutters Special

Innovation & Technology

You want your machining to be better. Custom end mill cutters use new technology. These tools have special designs for each job. You get more accuracy and smoother finishes. Carbide end mills with strong coatings last longer. They work well in hard jobs. Special shapes help you make things that normal tools cannot. For example, a marine company used a custom roughing end mill. It had chip-breaking geometry. This tool cut their tool count in half. It also made machining faster. Custom end mills help you work quicker and get great results.

Special designs for your needs

More accuracy and smooth cuts

Faster and better work

Strong coatings make tools last longer

Special shapes for hard jobs

Customization Capabilities

You need tools that fit your job. Customization lets you choose the best carbide end mills. Cutting tool makers give you custom solutions. These tools work better and last longer. You get tools that fit your job perfectly. Custom end mills help you get the accuracy you want.

Custom solutions for each job

Best tools for your work

More accuracy and stronger tools

Better results in machining

Quality Assurance

You want tools you can trust. Top makers follow strict rules for quality. Certifications like ISO 9001 and AS9100 show they care about quality. These rules make sure you get good carbide end mills.

| Certification | What It Means |

| ISO 9001 | Makes sure products are always good |

| AS9100 | Checks quality for aerospace tools |

Global Reach

You need help wherever you work. Top custom end mill makers sell tools worldwide. You get good carbide end mills no matter where you are. North America sets high standards for quality. Buyers everywhere trust these tools for their new features. As industries like electric cars and clean energy grow, you get the newest custom end mills. Global sales mean you always get the best tools.

Manufacturer Profiles

Country

Custom end mill suppliers are found in many places. China, the USA, Italy, Sweden, Israel, and Japan have top makers. Each country has its own way of making tools. Italy uses old skills and new machines. Sweden helps customers all over the world. Japan is best at tiny carbide end mills and electronics. You can pick from suppliers everywhere. This helps you find the best one for your job.

Core Strengths

You want every cut to be smooth and exact. The best suppliers work hard on these things:

Precision engineering gives smooth cuts and tight fits

Carbide end mills work well for hard jobs

Custom solutions help with special tasks

Quality checks happen at every step

Fast shipping and good customer service

Harvey Tool is great for value and performance. Kyocera and Niagara Cutter make new designs for better finishes. These suppliers give you good results every time.

Unique Offerings

You need custom end mills that match your job. Each supplier has something special. Look at this table to see what makes them different:

| Manufacturer | Unique Offerings |

| Kyocera | Special shapes, many sizes, focus on quality and precision |

| Harvey Tool | Tiny carbide end mills, coolant channels, high-performance tools |

| OSG Corporation | Carbide end mills with DUROREY coatings, different shapes, tools for tough jobs |

| Niagara Cutter | Special shapes, many types, advanced making for smooth finishes |

You can find custom end mills for any job. Suppliers make tools for aluminum, steel, and other metals. There are choices for tiny jobs and big projects.

Industries Served

Custom end mill suppliers help many industries. Aerospace needs exact tools for plane parts. Cars use carbide end mills for their parts. Metalworking uses custom end mills to cut metal fast. Electronics, healthcare, and optics also need precise tools.

| Industry | Description |

| Aerospace | Exact cutting tools for plane parts |

| Automotive | Strong end mills for car parts |

| Metalworking | Custom end mills for cutting metal fast |

You can find the right supplier for your work. If you work in aerospace or metalworking, you get custom tools that help you do better and get good quality.

End Mill Brands Comparison Table

Table Overview

You want to pick the best custom end mill for your job. A comparison table helps you see how top brands compare. You can find differences in carbide end mills, performance, and precision. This table gives you a quick look at what each brand has. Use it to find the right one for your shop or project. Each manufacturer has something special. Some focus on advanced coatings. Others are best at custom solutions or worldwide support. You get a clear view of quality, product choices, and how well they work.

| Manufacturer | Market Share | Product Range | Customization | Quality | Global Reach |

| Hiboo Tool | High | Wide (carbide end mills, drills, reamers) | Yes | High | Global |

| Shenzhen Zhuoluoyu | Strong | Carbide end mills, CNC tools | Yes | High | Asia, Europe |

| DATRON Dynamics | Moderate | High-speed carbide end mills | Yes | High | North America |

| Melin Tool | Moderate | Carbide end mills, custom tools | Yes | High | USA |

| Utensileria Carmon Srl | Notable | Carbide end mills, roughers | Yes | High | Europe |

| Sandvik Coromant | Leading | Full range, advanced coatings | Yes | High | Global |

| Kennametal | Leading | Carbide end mills, specialty tools | Yes | High | Global |

| ISCAR | Leading | Carbide end mills, custom shapes | Yes | High | Global |

| EndMillMan.com LLC | Niche | Large inventory, custom end mills | Yes | High | USA |

| Union Tool | Strong | Carbide end mills, PCB drills | Yes | High | Global |

Use this table to compare brands easily. You can see which ones have the most precision, the biggest product range, or the best worldwide help.

Key Metrics

When you compare custom end mill brands, you should look at key things. These help you judge how well the tools work. Here are the main things to check:

Material: This changes how long the tool lasts and how it works with metals.

Coatings: These help tools work better by lowering friction and handling heat.

Flute Configuration: This affects how chips move and how smooth your cut is.

Cutting Diameter: This sets the size of your cut and how strong the tool is.

Cutting Speed: This tells you how fast you can finish your job.

You want carbide end mills that work well and are precise. Some brands, like Cleveland and Kyocera, have special flute shapes and advanced coatings. Others, like Niagara Cutter, make tools that last longer for soft metals. You can find custom end mills for any machining job, from roughing to fine finishing. Always check these things before you buy. They help you get the best results in your shop.

Choosing Cutting Tool Manufacturers

Material & Application

Pick the right tool for your job. First, think about what you need to cut. Some carbide end mills work better with metal. Others are best for plastic. Aerospace projects need special shapes and high precision. These tools help make light parts. Cars use end mills for aluminum and composites. Medical devices need tools that make exact cuts. They also need smooth finishes. Electronics use tiny tools for circuit boards. Mold and die making needs cutters that keep tight tolerances. General manufacturing uses end mills for many tasks. Always match your tool to the material and job. This helps you get good results and accuracy.

Support & Service

You should get good help from your manufacturer. The best companies give you technical support when you need it. They answer questions and fix problems fast. They help you pick the right carbide end mills. Many companies offer warranties and check quality. You can trust their tools. Look for manufacturers who inspect every tool before shipping. They also give quick solutions if you have issues. Good support keeps your shop working well. It helps you keep high precision in every job.

| Support Feature | What You Get |

| Technical Help | Answers for tool selection and use |

| Problem Solving | Fast fixes for machining challenges |

| Warranty & Quality Checks | Confidence in tool reliability and performance |

| Quick Production | New tools made and delivered quickly |

Lead Times

You want your tools to arrive on time. Good manufacturers send carbide end mills quickly. This keeps your work moving. Some companies make custom end mills in just a few days. Fast lead times help you avoid waiting. Your projects stay on track. Always ask about delivery times before you buy. Pick a manufacturer who meets deadlines. They should keep their promises. This helps you keep your schedule and do your best work.

Pricing & Value

You want good value for your money. Price is important, but so is quality. Some manufacturers give discounts if you buy a lot. Always check if the tools meet standards like ISO 9001 or ANSI. Ask for samples to test how long the tool lasts. See if the surface finish is smooth. Look for companies with modern machines and a good reputation. The best value comes from tools that last longer and cut better. They should also come with strong support. Balance the cost with all the benefits you get from your carbide end mills.

Tip: Always look at both price and how well the tool works. The cheapest tool may not give you the accuracy or reliability you need.

You can see why these companies are leaders. They make good tools and help you do your best work. If you want to pick the right company for your job, follow these steps:

Make a list of good companies for your project.

Ask each company for a price quote.

Use a scorecard to pick the best factories.

Check your top choices with clear rules for machining.

Use a checklist to look at quality and standards.

Choose the company that will help you succeed.

Look at the comparison table and company profiles to help you decide. Contact the companies and start your next project feeling sure about your choice.

FAQ

What is a custom end mill cutter?

A custom end mill cutter is a tool made just for your job. You choose the size, shape, and material. This helps you get better results and makes your work easier.

How do you pick the right end mill manufacturer?

You look at quality, support, and delivery speed. Check if the company offers custom options. Ask for samples. Compare prices and see which brand fits your needs best.

Why do coatings matter on carbide end mills?

Coatings help your tool last longer. They reduce heat and wear. You get smoother cuts and save money because you replace tools less often.

Can you use custom end mills for different materials?

Yes, you can. Custom end mills work on steel, aluminum, plastic, and more. You pick the right tool for your material. This gives you cleaner cuts and better finishes.

How fast can you get custom end mills delivered?

Some companies ship in just a few days. Others may take two weeks. Always ask about lead times before you order. Fast delivery keeps your project on track.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg