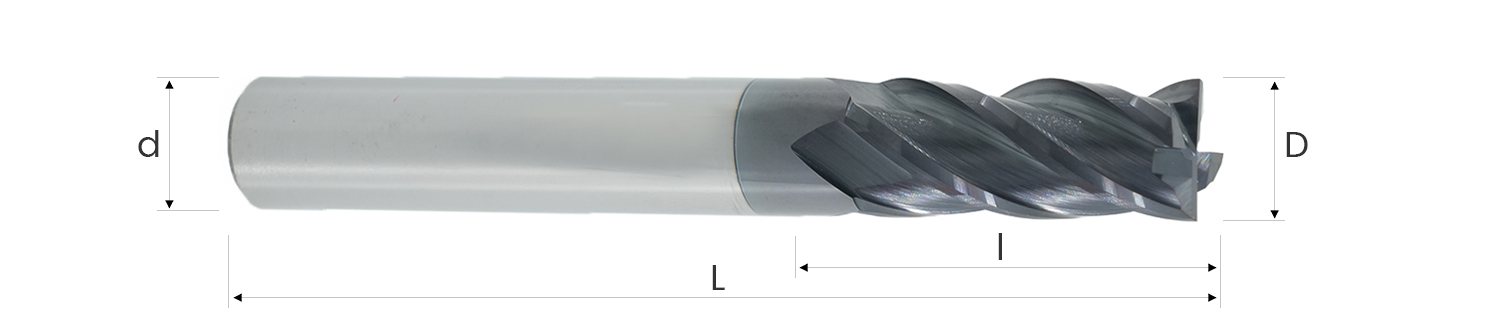

A square end mill, also known as a flat end mill, is a type of cutting tool used in milling operations. It has a flat bottom and straight cutting edges, making it ideal for machining flat surfaces, square corners, and shoulders. Square end mills are commonly used in a variety of materials, including metals, plastics, and wood.

Key Features of flat end mill:

Flat Bottom: This allows for the creation of flat surfaces and square corners.

Straight Cutting Edges: These edges enable the mill to cut cleanly and efficiently through the material.

Various Sizes and Coatings: HRC63 Square end mills come in different diameters, lengths, and with various coatings to enhance performance and tool life, such as TiN (Titanium Nitride) or TiAlN (Titanium Aluminum Nitride).

Flat bottom end mill Applications:

Face Milling: Creating a flat surface on the workpiece.

Slot Milling: Cutting slots into the material.

Side Milling: Machining the sides of a workpiece.

Contour Milling: Machining complex shapes with flat surfaces and sharp corners.

Material Considerations:

High-Speed Steel (HSS): Good for general-purpose milling.

Carbide: Offers higher cutting speeds and longer tool life, suitable for harder materials.

Cobalt: Provides better wear resistance and toughness than HSS.

| D(Diameter of cut) | d(Shank Diameter) | l(Flute Length) | L(Overall Length) |

| 1 | 3 | 4 | 50

|

| 1.5 | 4 | 4 | 50 |

| 2 | 6 | 4 | 50 |

| 2.5 | 8 | 4 | 50 |

| 3 | 8 | 6 | 50 |

| 3.5 | 10 | 6 | 50 |

| 4 | 11 | 6 | 50 |

| 4.5 | 13 | 6 | 50 |

| 5 | 13 | 6 | 50 |

| 5.5 | 13 | 6 | 50 |

| 6 | 15 | 6 | 50 |

| 7 | 16 | 8 | 60 |

| 8 | 20 | 8 | 60 |

| 9 | 20 | 10 | 75 |

| 10 | 25 | 10 | 75 |

| 11 | 25 | 12 | 75 |

| 12 | 30 | 12 | 75 |

| 14 | 35 | 14 | 100 |

| 16 | 40 | 16 | 100 |

| 18 | 45 | 18 | 100 |

| 20 | 45 | 20 | 100 |

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg