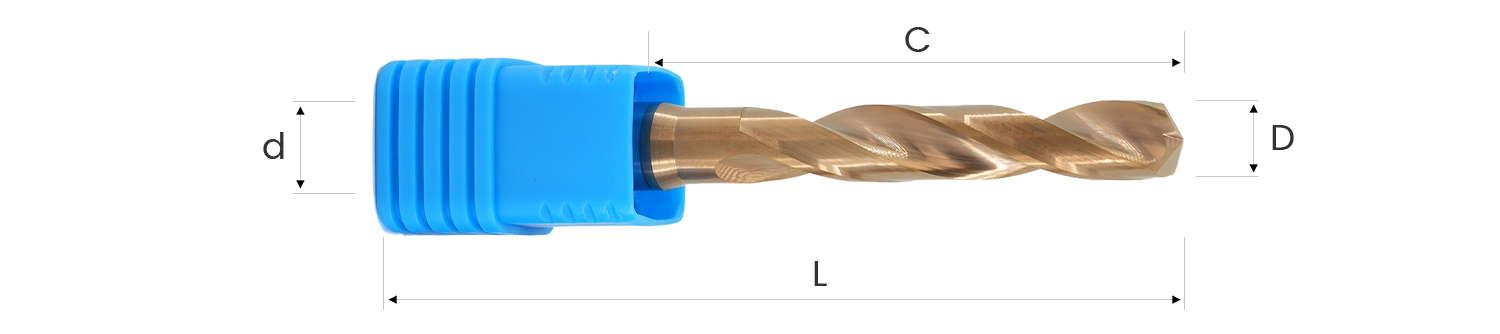

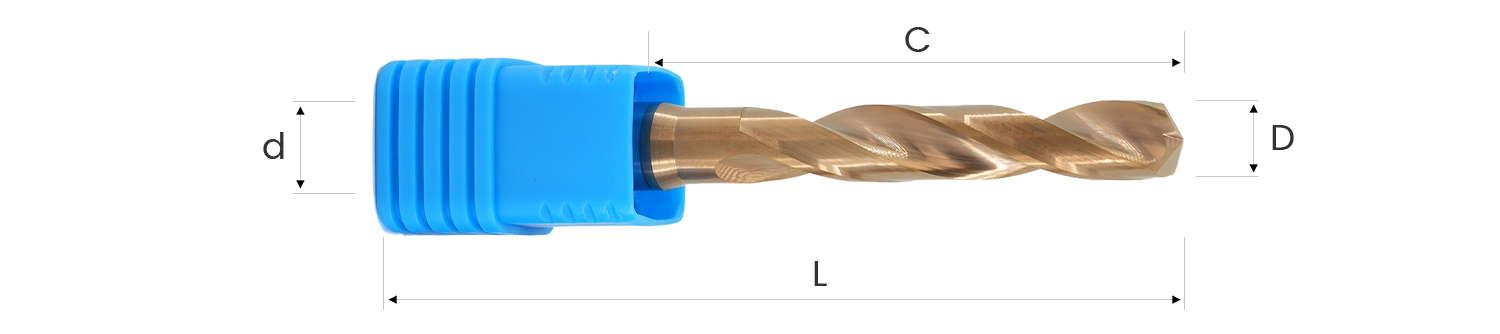

Structure and characteristics of Fried Dough Twists drill:

Flutes: The main feature of Fried Dough Twists bits is spiral grooves, which help remove chips and cool the bits. The number of slots is usually two, but there are also multiple slot designs.

Cutting Edges: located at the front end of the drill bit, responsible for cutting materials. The sharpness and angle of the cutting edge have a significant impact on drilling efficiency.

Shank: Used for installation in a drill chuck, usually circular or hexagonal in shape.

Point Angle: usually 118° or 135°. 118° is suitable for most materials, while 135° is typically used for hard materials such as stainless steel.

Classify by drill tip angle:

118° tip angle: The most common tip angle, suitable for most materials.

135° tip angle: Used for harder materials such as stainless steel, it can more effectively prevent slipping.

| Specifications |

| (d Dia.) | (I Length of Cut) | (D Shank Dia.) | O.A.L | (A) |

| 0.2 | 3 | 3D | 38L | 118° |

| 0.3 | 3 | 3D | 38L | 118° |

| 0.4 | 3 | 3D | 38L | 118° |

| 0.5 | 4 | 3D | 38L | 118° |

| 0.6 | 6 | 3D | 38L | 118° |

| 0.7 | 6 | 3D | 38L | 118° |

| 0.8 | 6 | 3D | 38L | 118° |

| 1.5 | 8 | 3D | 38L | 118° |

| 2.0 | 10 | 3D | 38L | 118° |

| 3.0 | 25 | 3D | 50L | 1180 |

| 4.0 | 25 | 4D | 50L | 118° |

| 5.0 | 25 | 5D | 50L | 118° |

| 6.0 | 25 | 6D | 50L | 118° |

| 7.0 | 30 | 7D | 60L | 118° |

| 8.0 | 40 | 8D | 75L | 118° |

| 9.0 | 40 | 9D | 75L | 118° |

| 10.0 | 40 | 10D | 75L | 118° |

| 11 | 45 | 11D | 100L | 118° |

| 12 | 50 | 12D | 100L | 118 |

| 12.5 | 50 | 12.5D | 100L | 118° |

| 13 | 50 | 13D | 100L | 118° |

| 9 | 50 | 9D | 100L | 130° |

| 12.3 | 60 | 12.3D | 120L | 130° |

| 12.3 | 65 | 12.3D | 130L | 130° |

| 13.8 | 50 | 13.8D | 100L | 130° |

| 13.8 | 60 | 13.8D | 120L | 130° |

| 12.55 | 90 | 13D | 150L |

|

| 12.55 | 90 | 14D | 150L |

|

| 14.5 | 70 | 14.5D | 140L |

|

| 16 | 75 | 16D | 150L | 118° |

Internal Cooling Drill Bit is commonly used for high-precision and high-efficiency metal processing, especially for deep hole drilling and hard material processing.

Characteristics of Internal Cold Drill:

Internal cooling channels: There are specially designed channels inside the drill bit, through which the coolant directly reaches the drilling area for efficient cooling and lubrication.

High efficiency: Due to its good cooling effect, internal cold drills can work at higher feed and cutting speeds, thereby improving machining efficiency.

Extending the lifespan of drill bits: Effective cooling and lubrication reduce friction and heat accumulation, extending the service life of drill bits.

Better hole quality: Internal cold drilling can better eliminate chips during the machining process, reduce friction and cutting resistance on the hole wall, thereby improving the quality and accuracy of the hole.

Suitable for deep hole machining: Internal cold drilling has significant advantages in deep hole machining, effectively preventing chip accumulation and drill bit overheating.

Application Area:

Aerospace industry: used for processing complex parts of high-strength and high-temperature alloy materials.

Automobile manufacturing: used for processing deep holes and high-precision holes for engines, transmissions, and other critical components.

Mold manufacturing: used for processing cooling water channels and other deep hole structures of molds.

Oil and gas extraction: used for the manufacturing of drilling equipment and tools.

Here are some common specifications examples of internal cooling drill bits:

Diameter: Ø 6mm, Ø 8mm, Ø 10mm, Ø 12mm

Effective drilling length: 20mm, 40mm, 60mm

Total length: 70mm, 100mm, 150mm

Number of cooling holes: 2

Material: Hard alloy

Cutting angle: 135°

Spot Drill Bits are mainly used to prevent the drill bit from shifting during subsequent drilling, improving the accuracy and quality of the hole.

Characteristics of Centering Drill Bit:

Short and sturdy: Centering drill bits are usually short and structurally sturdy to prevent vibration and displacement during drilling.

Center Precision: Designed to drill precise center points on workpieces, helping subsequent drill bits maintain the correct position.

Tip angle: There are usually larger tip angles (such as 90°, 120°, 142°) to ensure quick positioning and drilling.

Material: Usually made of high-speed steel (HSS) or hard alloy to provide sufficient hardness and wear resistance.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg