Product Description

Achieve mirror-quality, burr-free chamfers with our specialized Chamfering End Mill designed to prevent material buildup and maximize productivity in aluminum CNC machining.

Anti-Gumming Design: Features polished flutes and a sharp edge to prevent aluminum adhesion (BUE), ensuring a flawless finish.

Superior Chip Evacuation: A high helix angle and efficient flute design allow for rapid chip removal, preventing recutting and scratches.

Built for Speed: Made from solid micro-grain carbide, this Chamfering End Mill maintains rigidity and stability at high RPMs.

Application Versatility: Perfect for deburring, beveling, and edge-breaking on aluminum, brass, copper, and other non-ferrous metals.

Carbide Chamfering End Mill Description

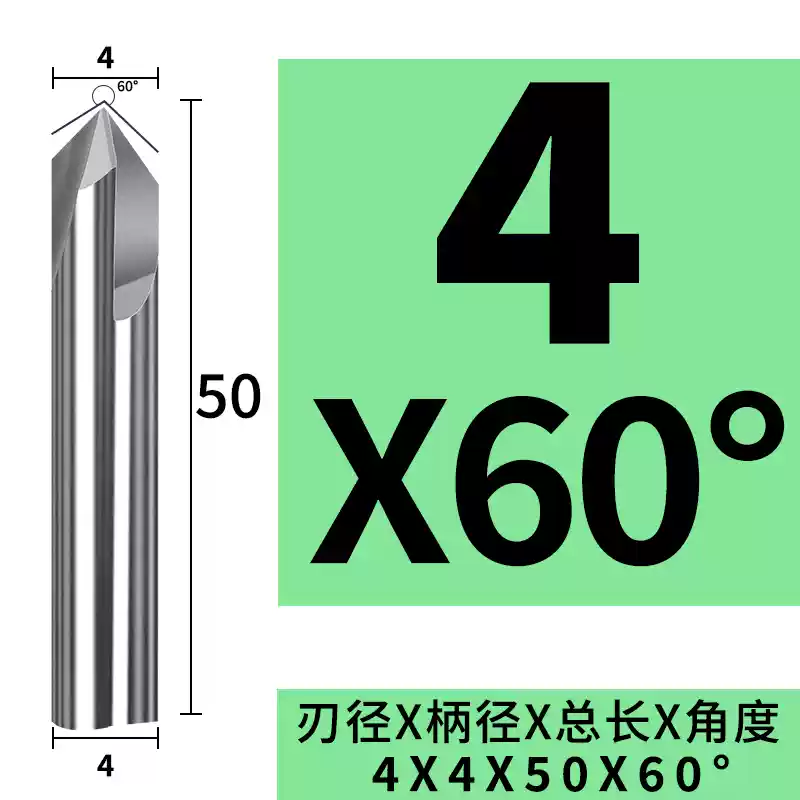

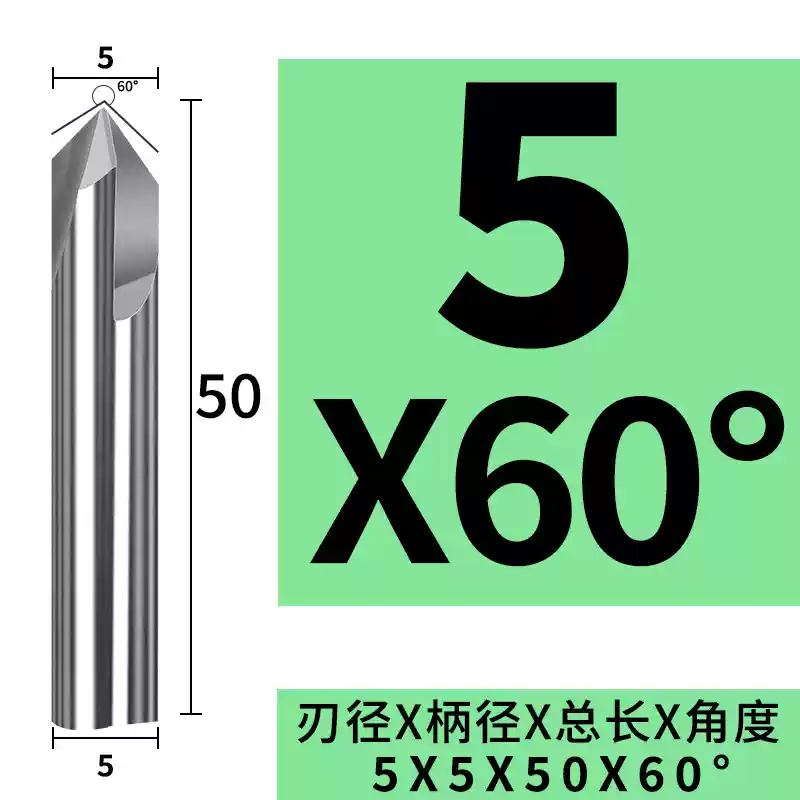

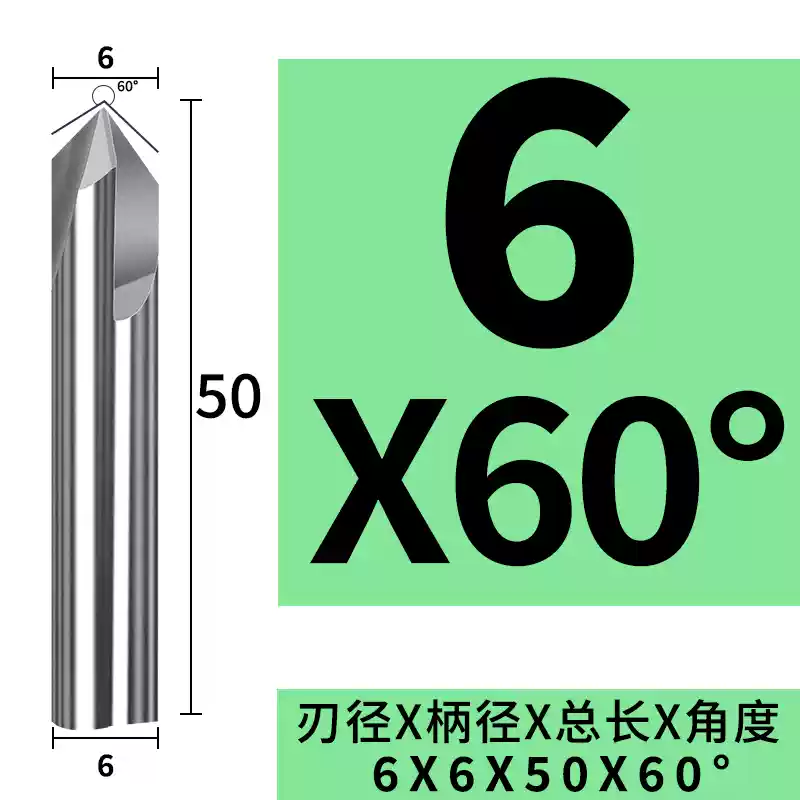

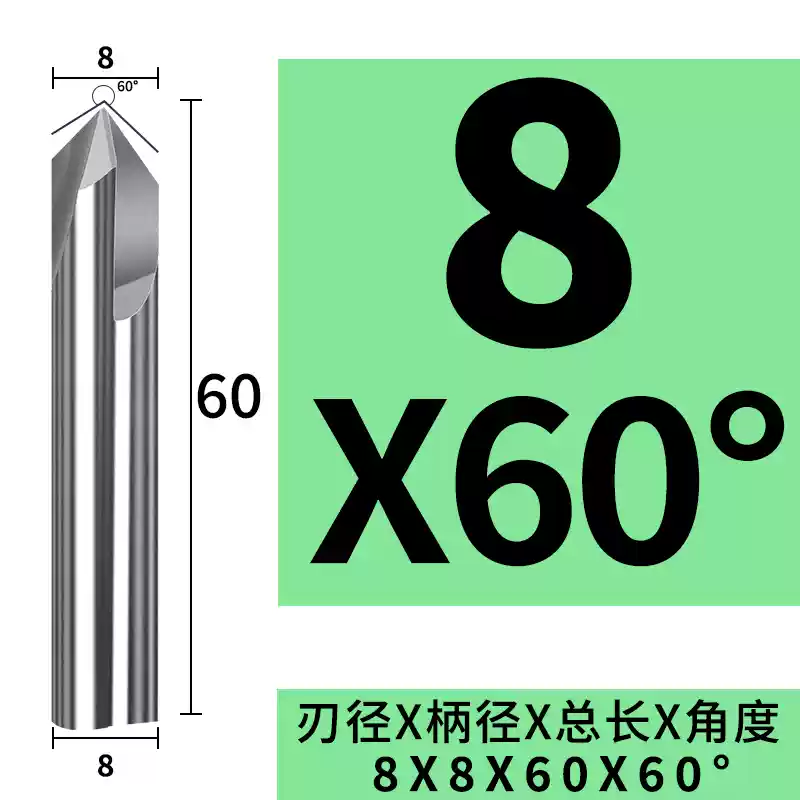

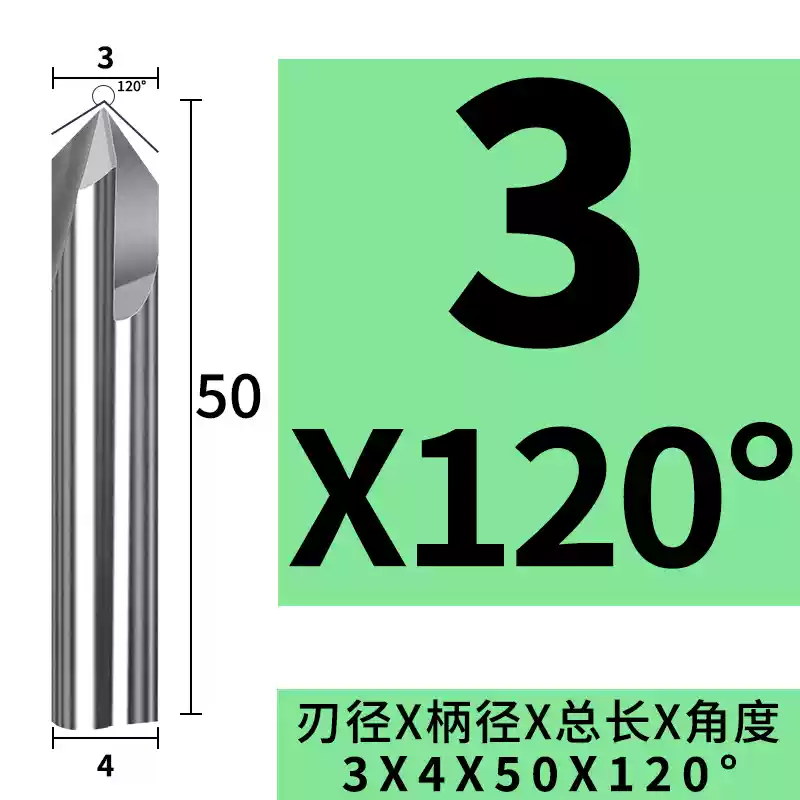

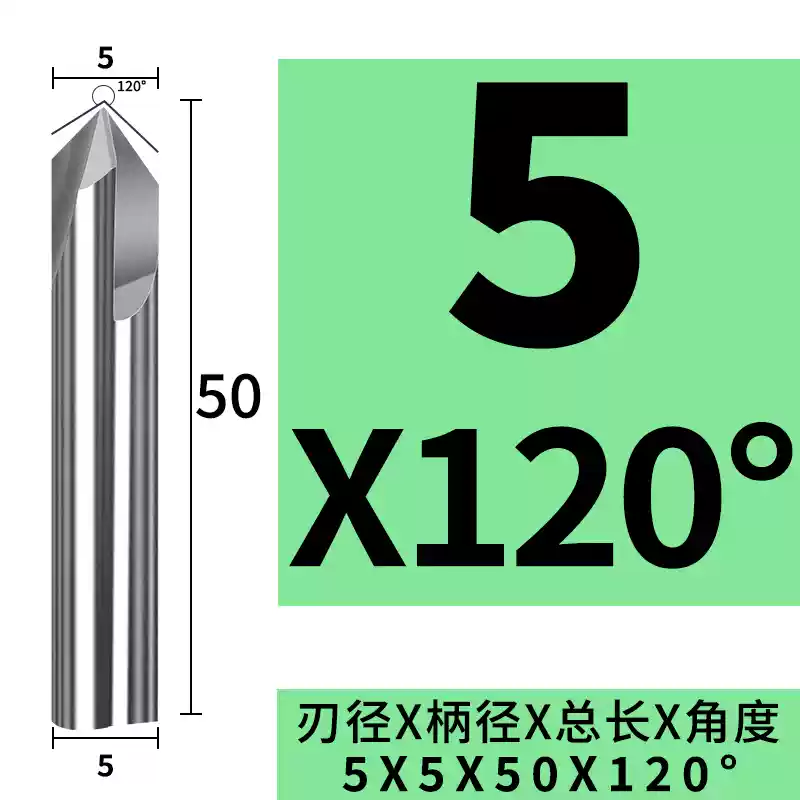

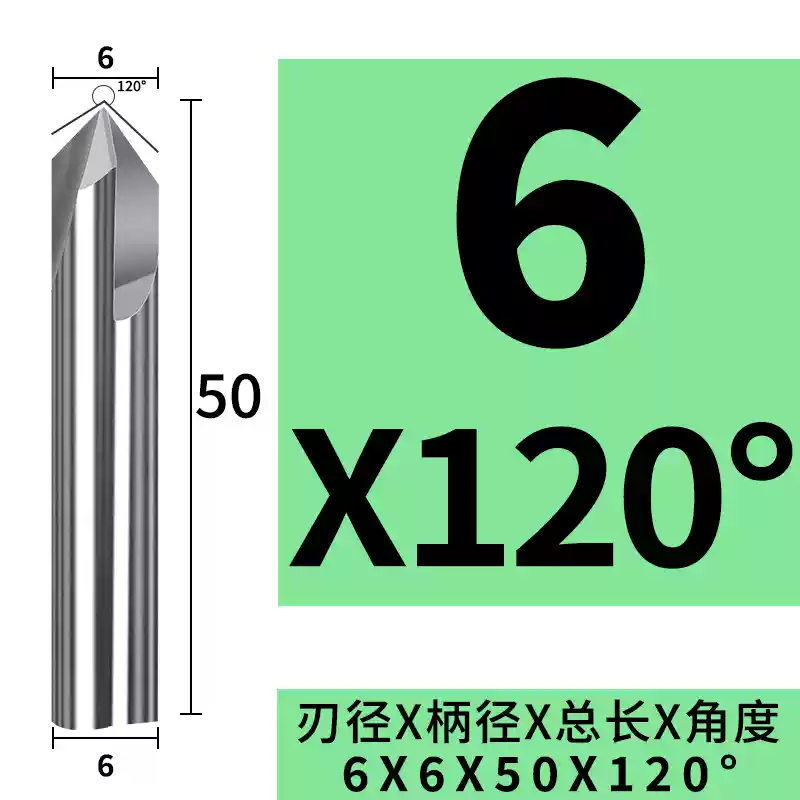

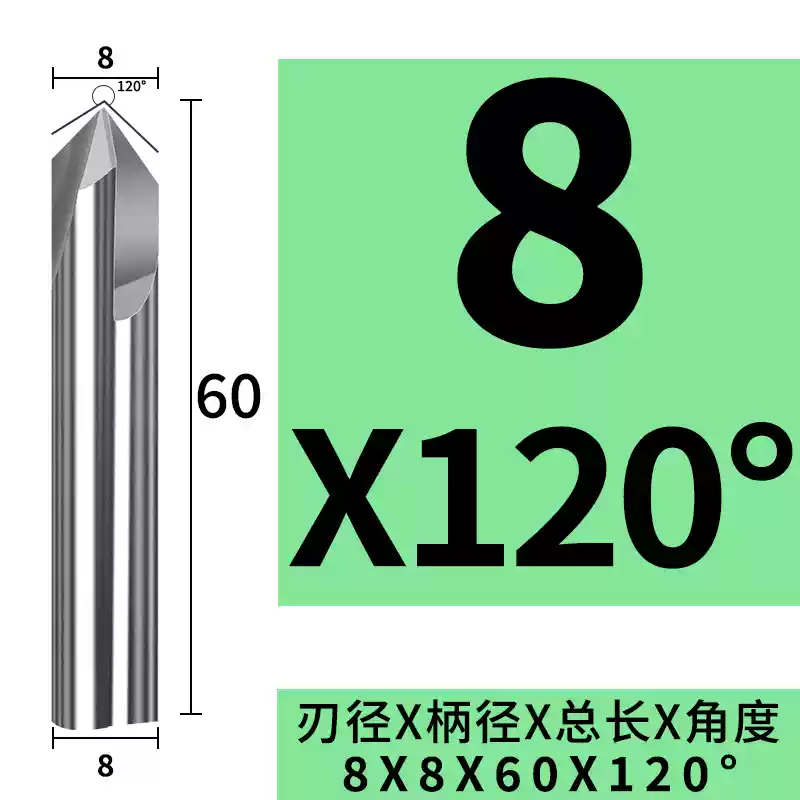

Name | Chamfer End Mill |

Material | Carbide |

Coating | AITiN/TiAlCN/TiSiN or customized |

HRC | 45/55/60/65 |

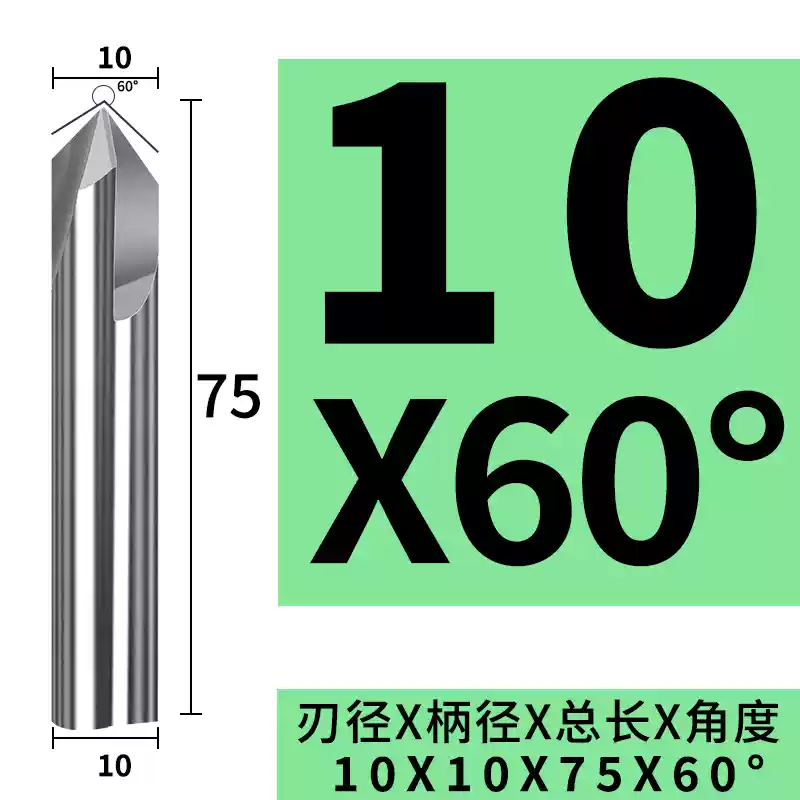

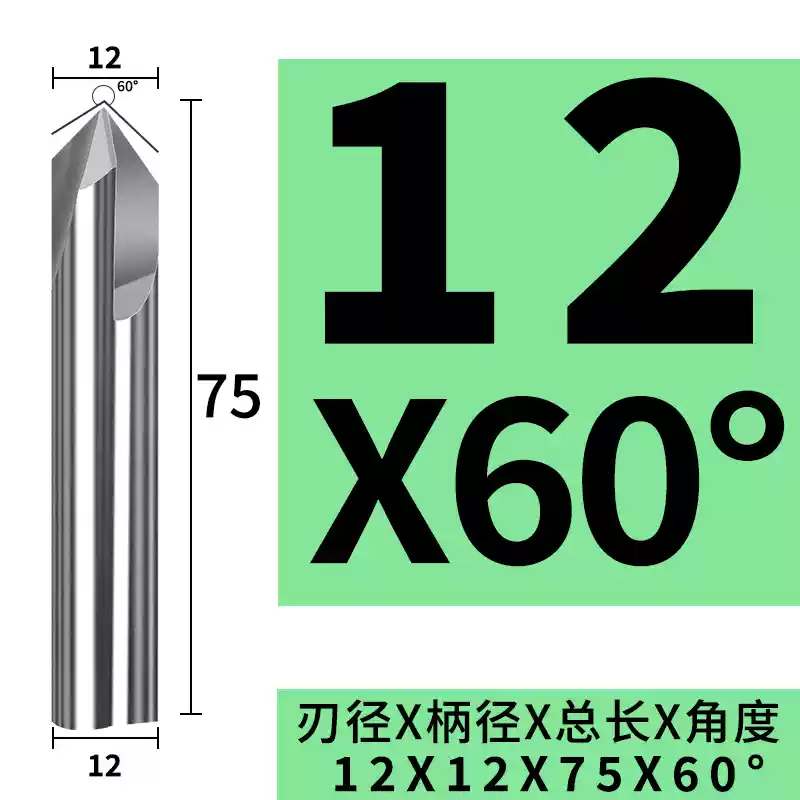

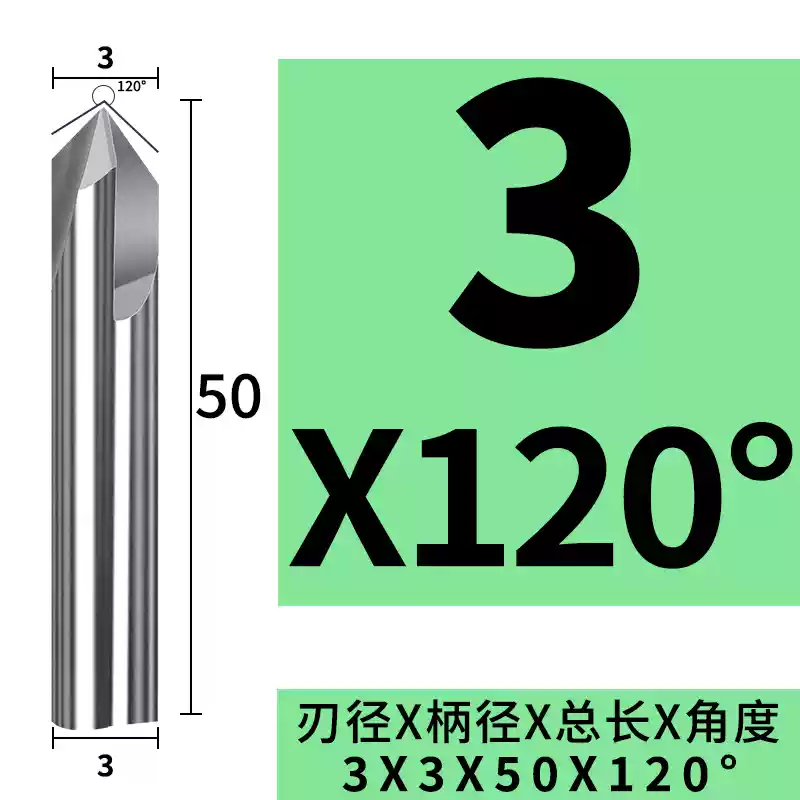

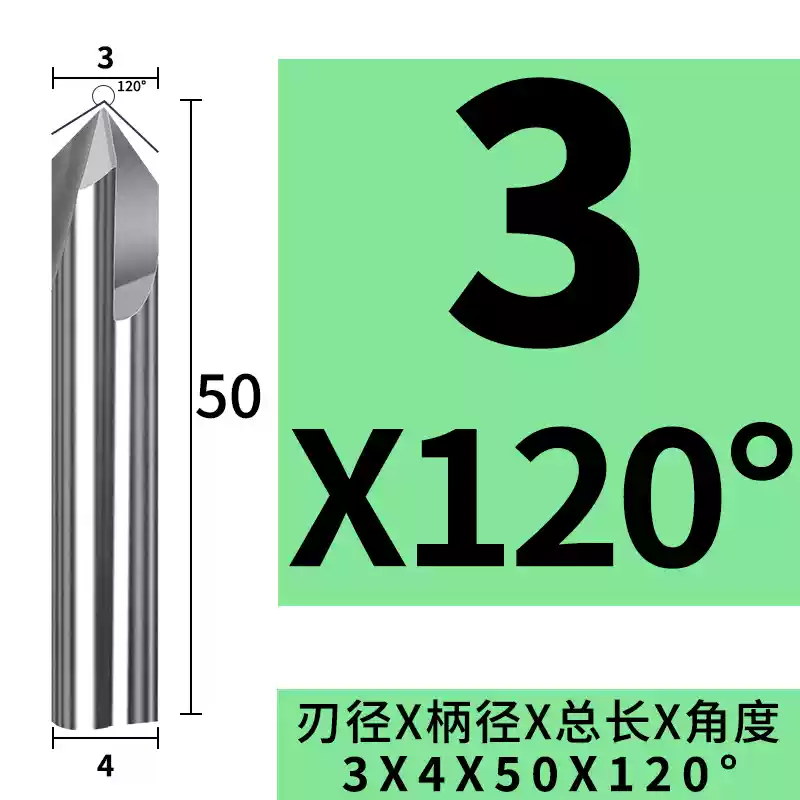

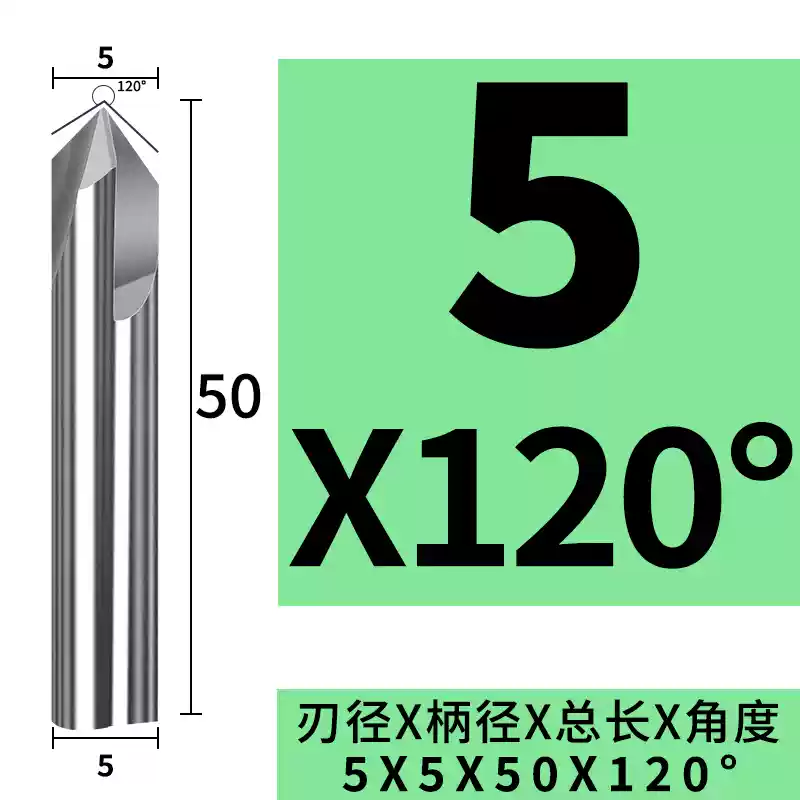

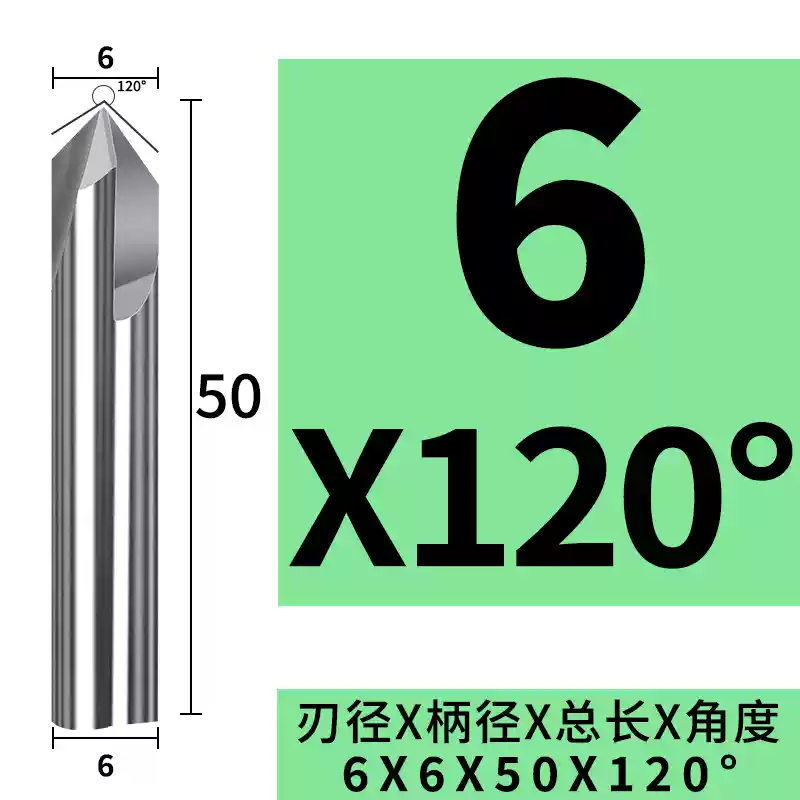

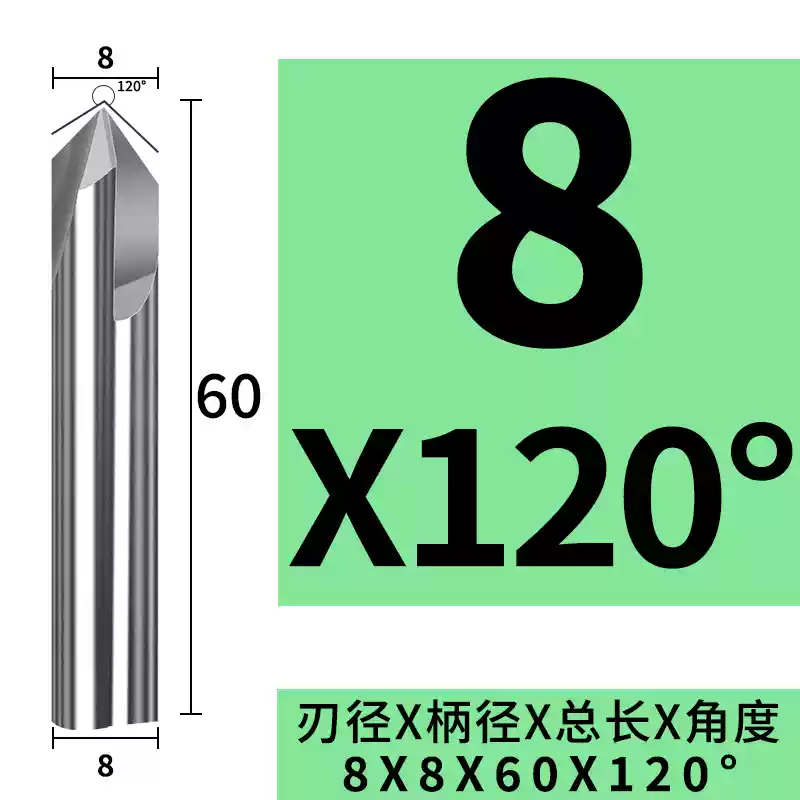

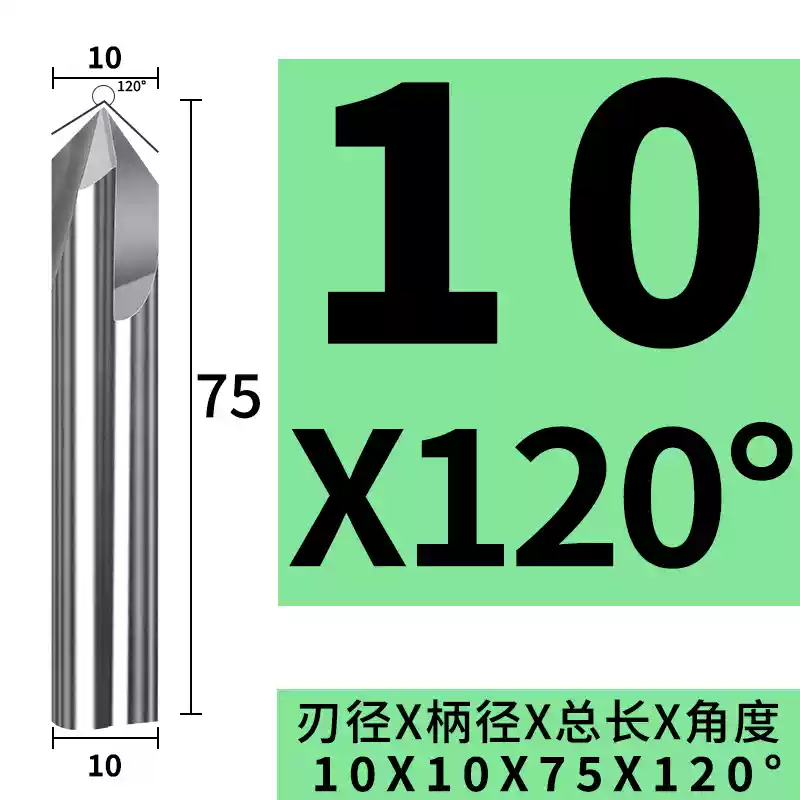

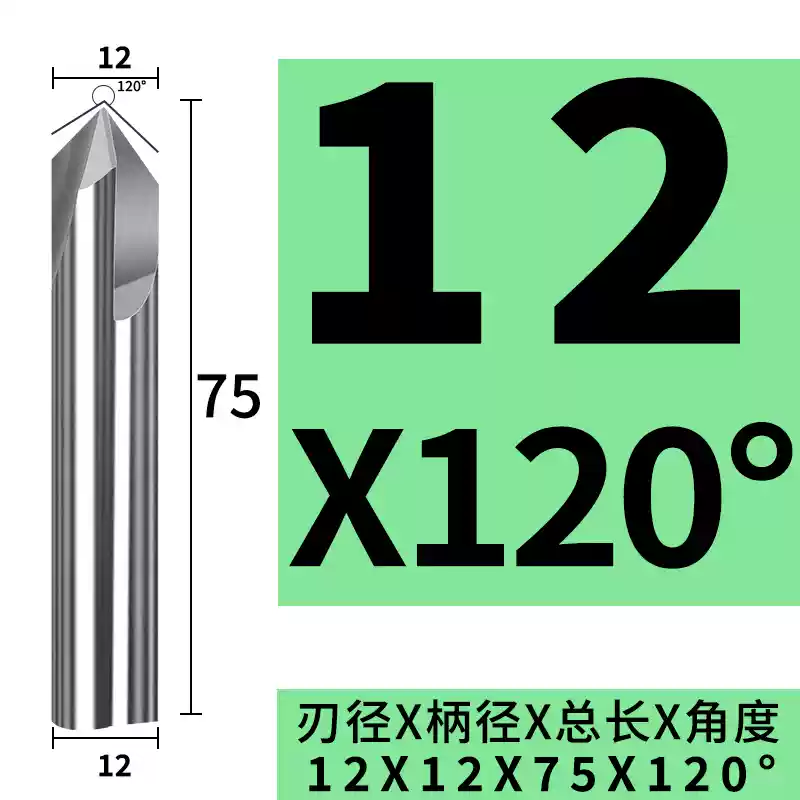

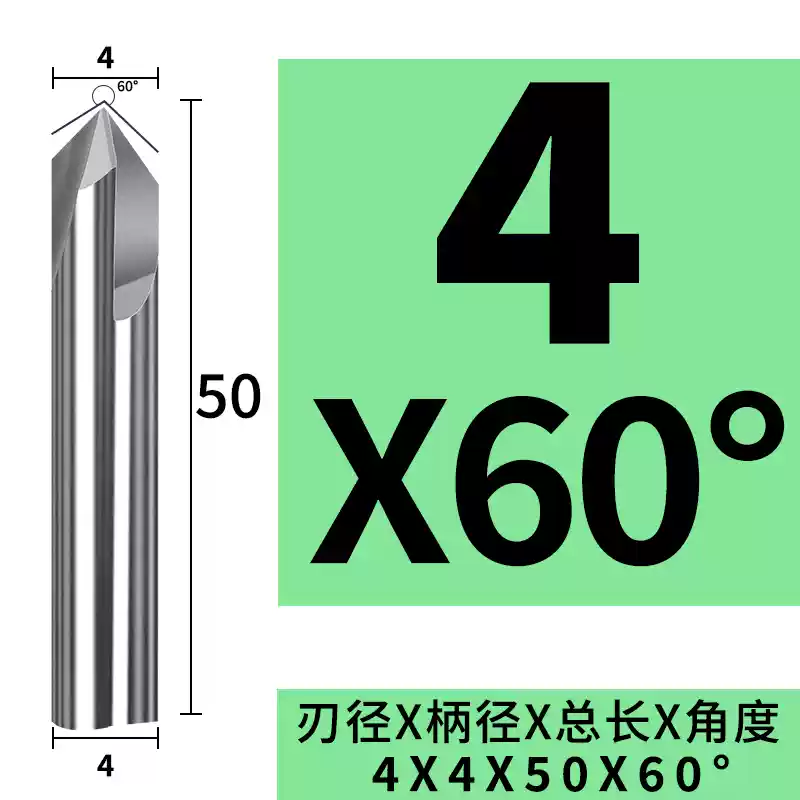

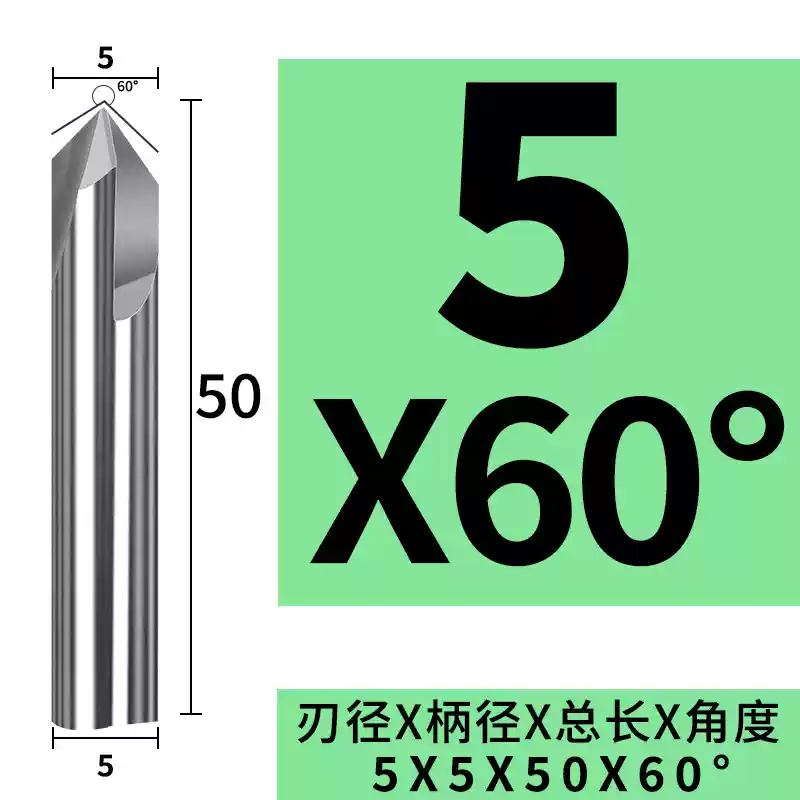

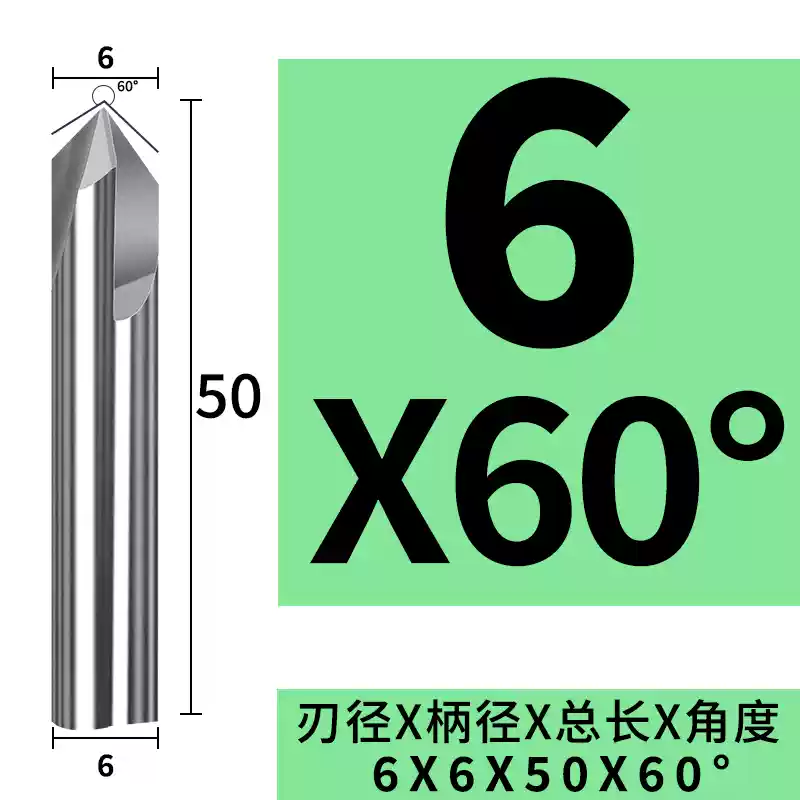

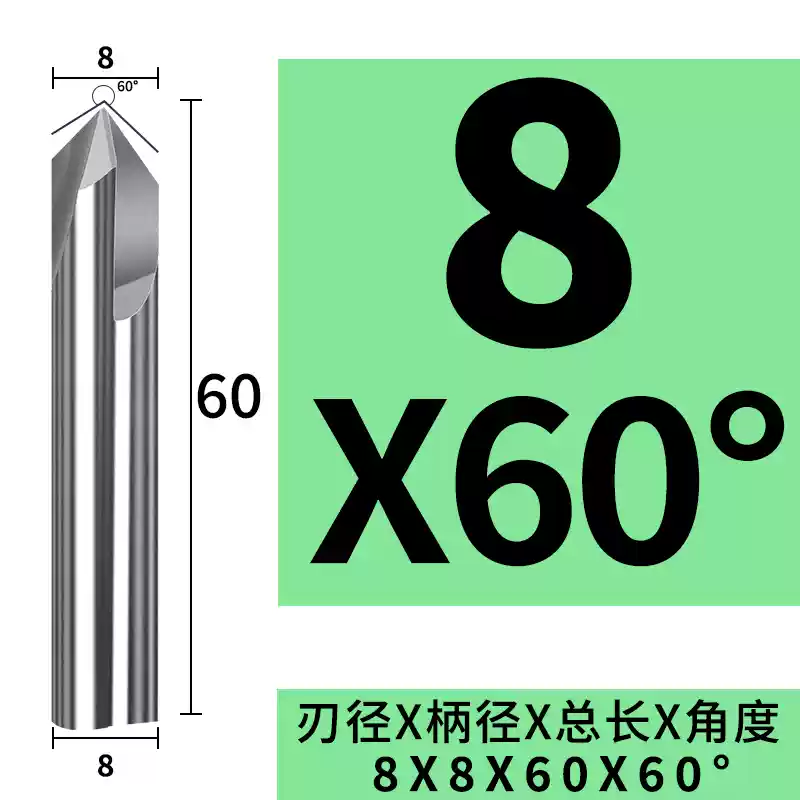

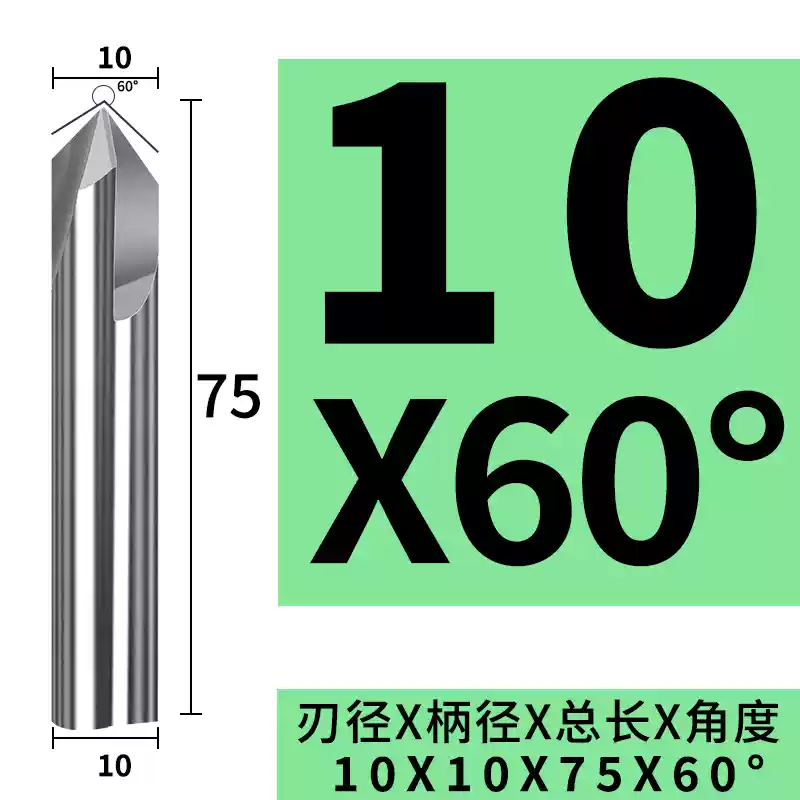

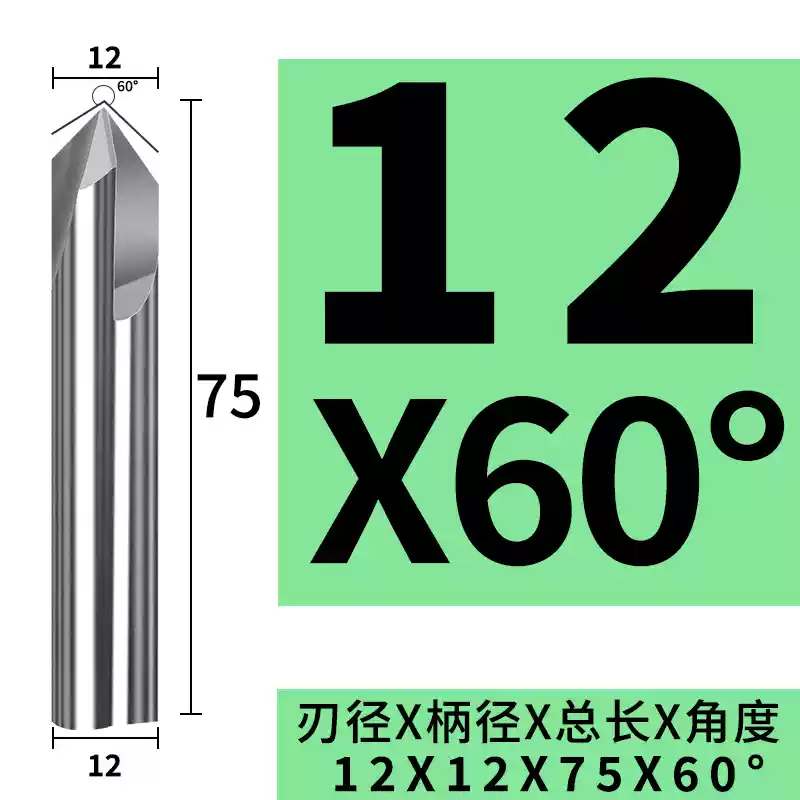

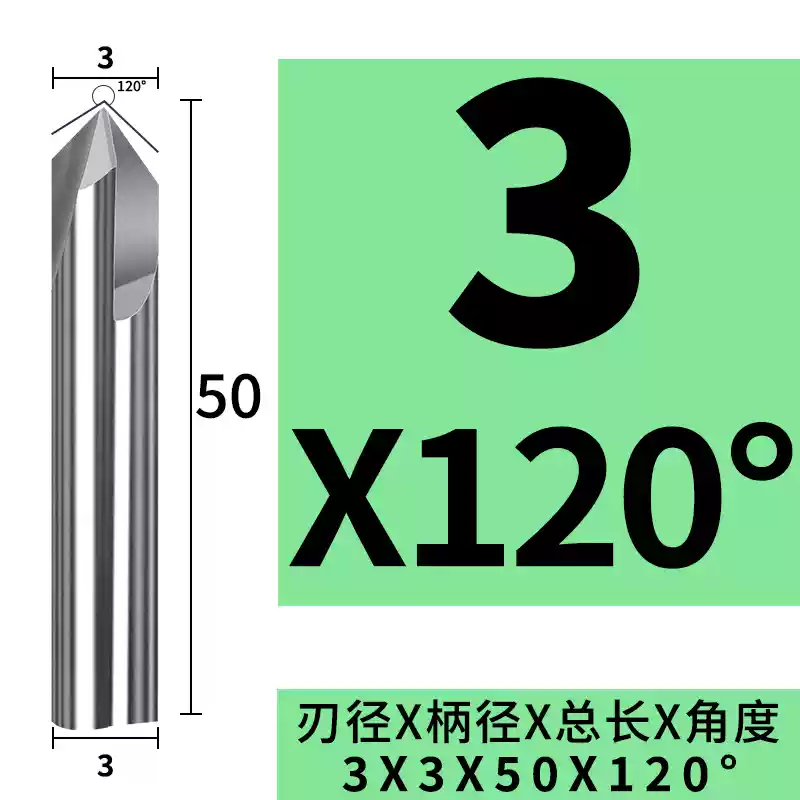

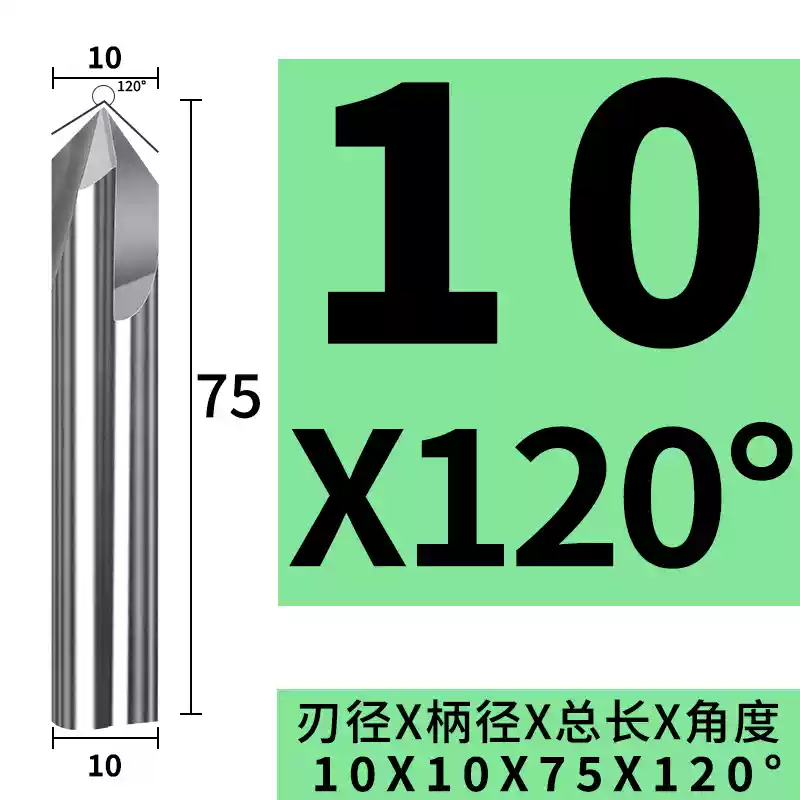

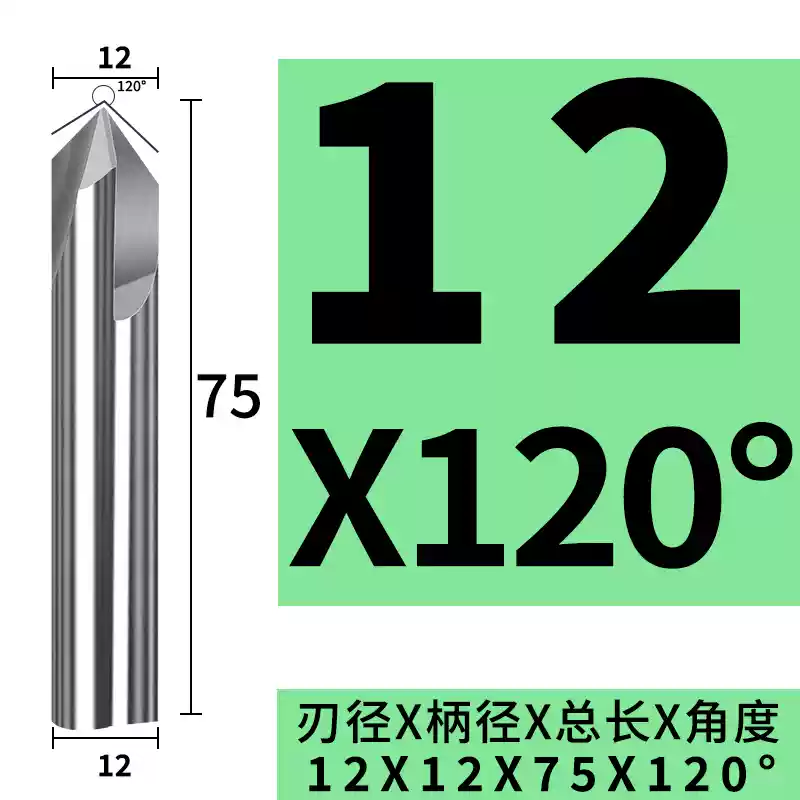

Diameter | 1.0mm-20mm or customized |

Overall Length | 50-150mm or customized |

HRC | 58 degree |

Angle | 60°/90°/120° |

Use | Metal Chamfering/Aluminum Chamfering |

Flute | 2 Flutes/3 Flutes |

Type | chamfering end mill,chamfering knife,chamfering milling cutter,chamfer tool |

Equipment | CNC machine, engraving machine |

Suitable for | 45# steel, cast iron, tool steel, abrasive steel and other materials within 53 degrees |

OEM | Yes and Welcome |

All the specs. can be customized |

Coated with TiSiN:Improve the speed and feed rate of the tool ,Improve the surface wear resistance

Note:

Please allow 1-3mm error due to manual measurement.

Due to the difference between different monitors, the picture may not reflect the actual color of the item

The Challenge of Chamfering Aluminum

Machining aluminum presents unique challenges, including material sticking to the cutting edge (Built-Up Edge) and forming stubborn burrs. Using a standard Chamfering End Mill often leads to poor surface finishes and frequent tool maintenance. Our tool is engineered specifically to overcome these issues.

Why This is The Ultimate Chamfering End Mill for Aluminum?

Eliminates Material Buildup: The core of this Chamfering End Mill is its highly polished flute surface and razor-sharp cutting edge. This specialized geometry drastically reduces the surface area for chips to adhere to, effectively preventing aluminum from gumming up the tool and ensuring a consistent, clean cut.

Engineered for High-Speed Performance: Constructed from premium solid carbide, this Chamfering End Mill possesses the rigidity required for high-speed machining operations without deflection. This results in precise chamfer angles and extended tool life, even under demanding conditions.

Optimized for Clean Finishes: The high helix angle and flute design are not just for strength; they create an efficient pathway for chips to be ejected quickly. This prevents delicate finished surfaces from being scratched by recirculating chips, guaranteeing the high-quality aesthetic required for critical parts.

Why Choose Our Hiboo Chamfering End Mill for Aluminum?

Precision Engineered for Non-Ferrous Metals: Our specialized chamfering end mill features a high-efficiency flute design with polished grooves and an optimized helix angle that ensures effortless chip evacuation. This prevents chip adhesion and re-cutting, delivering a smooth, burr-free finish on aluminum and other non-ferrous materials.

Superior Anti-BUild-Up Design: Crafted from premium micro-grain solid carbide, this chamfering end mill maintains exceptional sharpness while resisting material adhesion. The polished flutes and specialized geometry minimize friction and prevent aluminum buildup, ensuring consistent performance throughout the tool's extended service life.

Optimized for High-Speed Machining: Whether you need a 60° angle for delicate edges, a 90° for standard beveling, or a 120° for specific applications, this chamfering end mill maintains perfect geometry at high RPMs. Its balanced construction ensures vibration-free operation, guaranteeing precise, mirror-quality chamfers in every aluminum processing application.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg