Key Features:

Rounded Corners: The rounded edges provide a stronger cutting edge compared to square end mills, reducing the likelihood of chipping.

Versatility: Suitable for both roughing and finishing operations.

Improved Tool Life: The radius at the corners distributes stress more evenly, enhancing the tool's durability.

Applications:

Fillet Milling: Creating internal fillets in pockets and slots.

Profile Milling: Machining complex profiles with reduced tool wear.

Die and Mold Applications: Creating molds and dies with rounded internal corners to prevent stress concentrations.

General Purpose Milling: Useful for a wide range of milling tasks, offering a balance between flat and ball end mills.

Material Considerations:

Carbide: Provides excellent wear resistance and is ideal for high-speed applications and hard materials.

Benefits:

Reduced Chipping: The rounded edges are less prone to chipping, which is common in square end mills.

Better Surface Finish: Provides a smoother finish than square end mills, especially on complex surfaces.

Increased Tool Strength: The corner radius adds strength to the tool, making it suitable for more demanding applications.

Tips for Using Corner Radius End Mills:

Select the Appropriate Radius: Choose a corner radius that matches the requirements of your part geometry.

Optimize Feeds and Speeds: Adjust the milling machine's settings to match the material and desired surface finish.

Tool Path Planning: Plan your tool paths to minimize tool deflection and optimize machining efficiency.

Coolant and Lubrication: Use coolant and lubrication to enhance tool life and surface finish, especially in high-speed or heavy-duty applications.

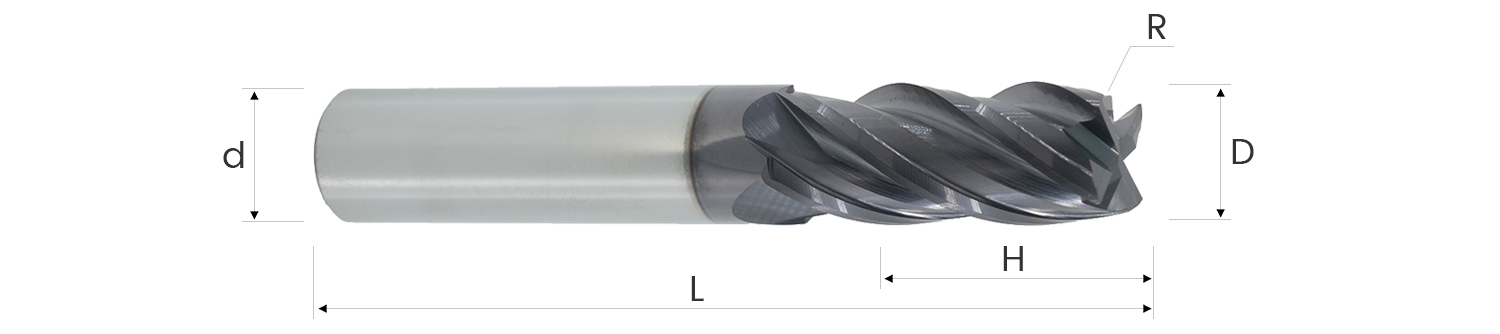

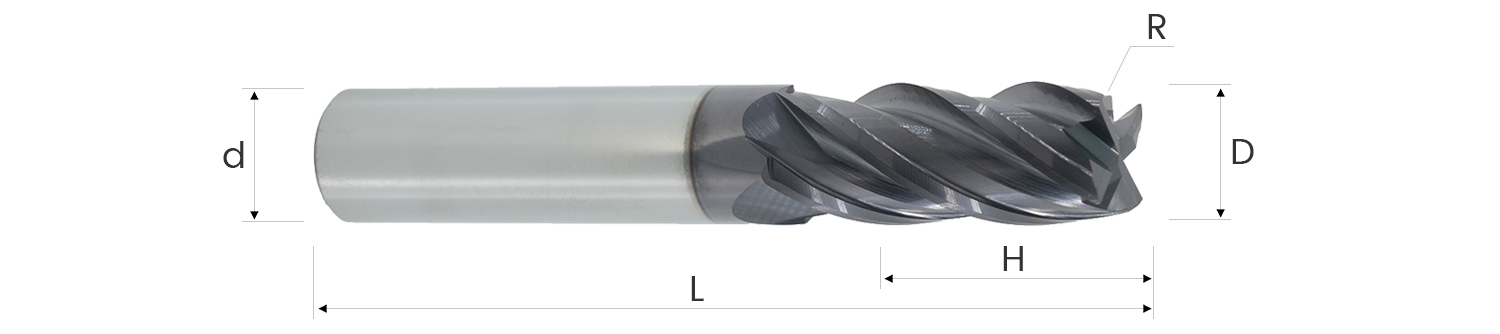

| Cutting | Flute | Shank | Corner | A.0.L |

| D | l | d | R Corner | L |

| 1 | 3 | 4 | R0.2 | 50 |

| 1 | 3 | 4 | R0.3 | 50 |

| 1.5 | 4 | 4 | R0.2 | 50 |

| 1.5 | 4 | 4 | R0.3 | 50 |

| 2 | 6 | 4 | R0.2 | 50 |

| 2 | 6 | 4 | R0.3 | 50 |

| 2.5 | 6 | 4 | R0.2 | 50 |

| 2.5 | 6 | 4 | R0.5 | 50 |

| 3 | 8 | 3 | R0.3 | 50 |

| 3 | 8 | 3 | R0.5 | 50 |

| 3 | 8 | 4 | R0.3 | 50 |

| 3 | 8 | 4 | R0.5 | 50 |

| 4 | 10 | 4 | R0.5 | 50 |

| 4 | 10 | 4 | R1.0 | 50 |

| 4 | 10 | 6 | R0.5 | 50 |

| 4 | 10 | 6 | R1.0 | 50 |

| 5 | 13 | 6 | R0.5 | 50 |

| 5 | 13 | 6 | R1.0 | 50 |

| 6 | 15 | 6 | R0.5 | 50 |

| 6 | 15 | 6 | R1.0 | 50 |

| 8 | 20 | 8 | R0.5 | 60 |

| 8 | 20 | 8 | R1.0 | 60 |

| 8 | 20 | 8 | R1.5 | 60 |

| 10 | 25 | 10 | R0.5 | 75 |

| 10 | 25 | 10 | R1.0 | 75 |

| 10 | 25 | 10 | R1.5 | 75 |

| 10 | 25 | 10 | R2.0 | 75 |

| 12 | 30 | 12 | R0.5 | 75 |

| 12 | 30 | 12 | R1.0 | 75 |

| 12 | 30 | 12 | R1.5 | 75 |

| 12 | 30 | 12 | R2.0 | 75 |

| 3 | 8 | 3 | R0.3 | 75 |

| 3 | 8 | 3 | R0.5 | 75 |

| 3 | 8 | 4 | R0.5 | 75 |

| 3 | 8 | 4 | R1.0 | 75 |

| 4 | 10 | 4 | R0.5 | 75 |

| 4 | 10 | 4 | R1.0 | 75 |

| 4 | 10 | 6 | R0.5 | 75 |

| 4 | 10 | 6 | R1.0 | 75 |

| 5 | 13 | 6 | R0.5 | 75 |

| 5 | 13 | 6 | R1.0 | 75 |

| 6 | 15 | 6 | R0.5 | 75 |

| 6 | 15 | 6 | R1.0 | 75 |

| 8 | 20 | 8 | R0.5 | 100 |

| 8 | 20 | 8 | R1.0 | 100 |

| 8 | 20 | 8 | R1.5 | 100 |

| 10 | 25 | 10 | R0.5 | 100 |

| 10 | 25 | 10 | R1.0 | 100 |

| 10 | 25 | 10 | R1.5 | 100 |

| 10 | 25 | 10 | R2.0 | 100 |

| 12 | 30 | 12 | R0.5 | 100 |

| 12 | 30 | 12 | R1.0 | 100 |

| 12 | 30 | 12 | R1.5 | 100 |

| 12 | 30 | 12 | R2.0 | 100 |

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

বাংলা

Hrvatski

Gaeilge

Oʻzbekcha

latviešu

Беларуская мова

Български

Lietuvių

Gaelo Albannach

ئۇيغۇرچە

Cymraeg